Anti-antipolar catalyst for fuel cell and preparation method and application of anti-antipolar catalyst

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor material durability, large catalyst size, and easy agglomeration, and achieve the effects of increasing difficulty, reducing residual volume, and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a fuel cell anti-reversed catalyst, the preparation method of the catalyst is as follows:

[0039] (1) Dissolve 10mg of chloroiridic acid and 70mg of polyvinylpyrrolidone in sodium hydroxide solution, keep stirring until the solution is clear while ensuring pH = 13-14, heat up to 80°C while continuing to stir until the solvent is almost completely removed ;

[0040] (2) Transfer the solvent-removed mixture to a muffle furnace, heat-treat at 500° C. for 1 h and cool to room temperature, then wash in a hydroalcoholic solution to obtain a fuel cell anti-reverse catalyst;

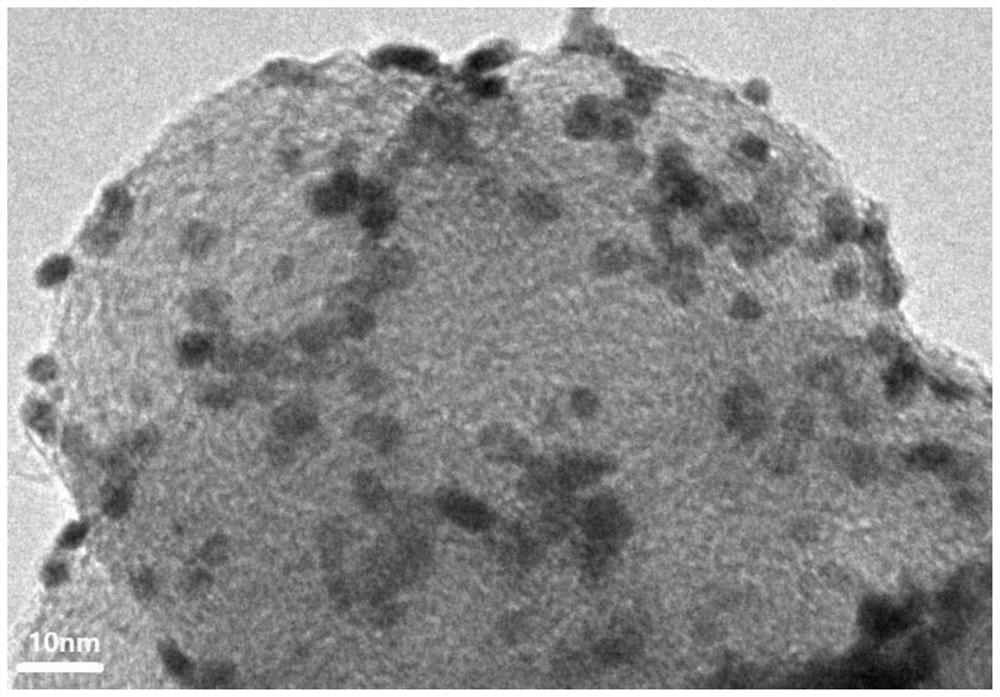

[0041] The SEM figure of described catalyst is as figure 1 shown by figure 1 It can be seen that the present invention prevents the catalyst particles from agglomerating and growing up well by adding a surfactant as a stabilizer, so that the final catalyst particle size is smaller, and at the same time, the surface is removed by high-temperature heat treatment and a combination...

Embodiment 2

[0043] This embodiment provides a fuel cell anti-reversed catalyst, the preparation method of the catalyst is as follows:

[0044] (1) Dissolve 10 mg of iridic acid acetate and 75 mg of polyvinylpyrrolidone in an alkaline solution, keep stirring until the solution is clear and ensure pH = 13-14, and heat up to 75° C. while continuing to stir until the solvent is almost completely removed;

[0045] (2) The solvent-removed mixture was transferred to a muffle furnace, heat-treated at 400° C. for 1 h, cooled to room temperature, and then washed in a hydroalcoholic solution to obtain a fuel cell anti-reverse catalyst.

Embodiment 3

[0047]This embodiment provides a fuel cell anti-reversed catalyst, the preparation method of the catalyst is as follows:

[0048] (1) Dissolve 10 mg of chloroiridic acid and 70 mg of sodium lauryl sulfate in sodium hydroxide solution, continue to stir until the solution is clear and ensure pH = 13-14, and heat up to 80 ° C while continuing to stir until the solvent almost completely removed;

[0049] (2) The solvent-removed mixture was transferred to a muffle furnace, heat-treated at 400° C. for 1 h, cooled to room temperature, and then washed in a hydroalcoholic solution to obtain a fuel cell anti-reverse catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com