A kind of preparation method of positive electrode conductive agent and conductive agent slurry of lithium ion battery

A lithium-ion battery and conductive agent technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of high energy consumption, complex preparation process, etc., and achieve a large contact area, simple preparation process, and high productivity short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

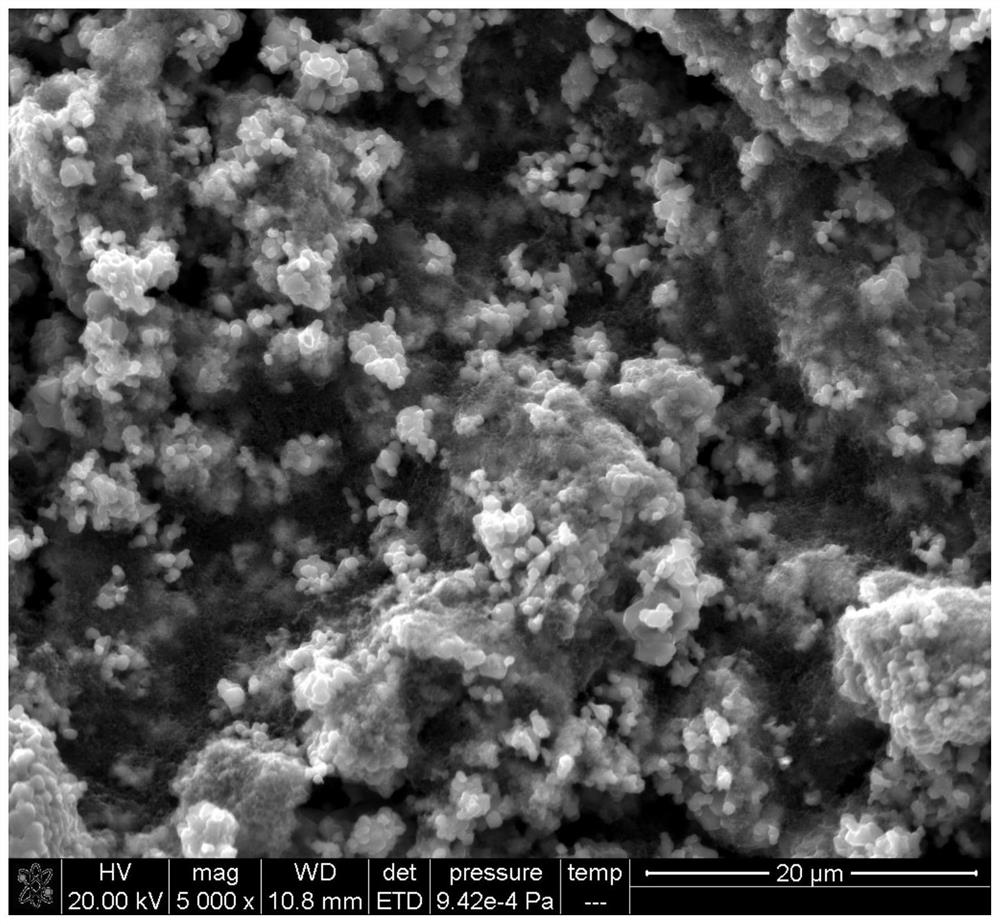

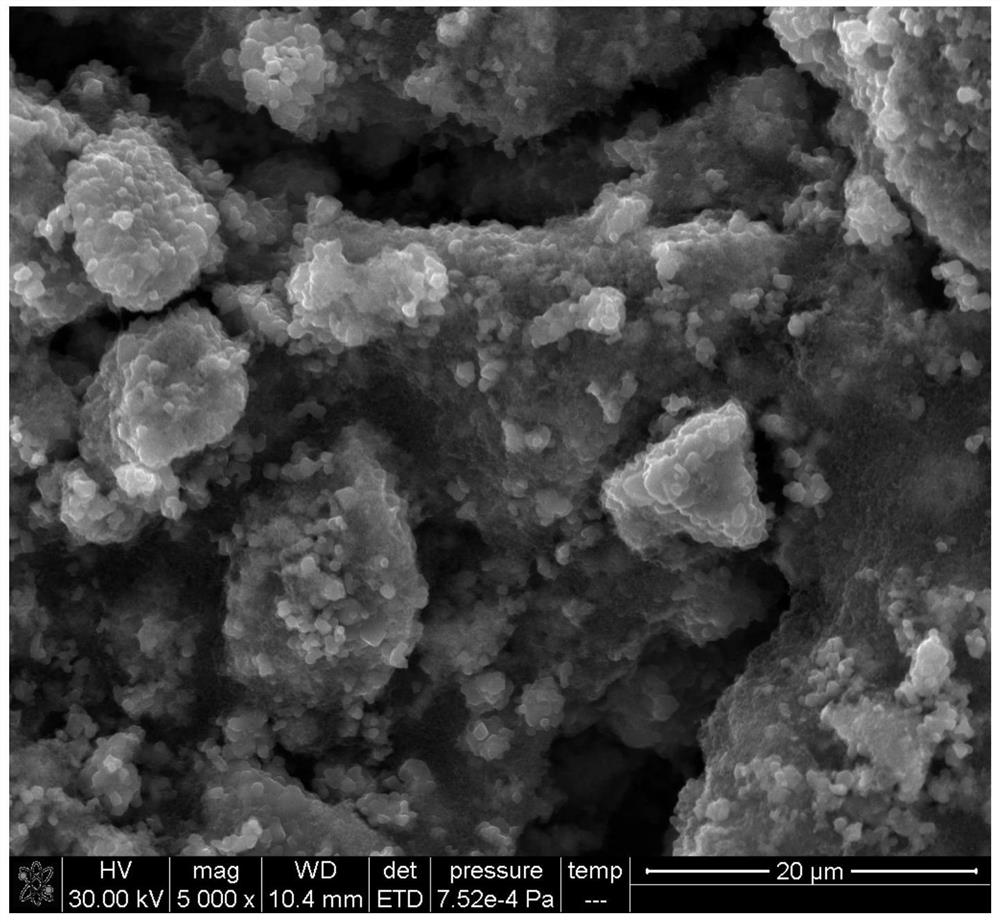

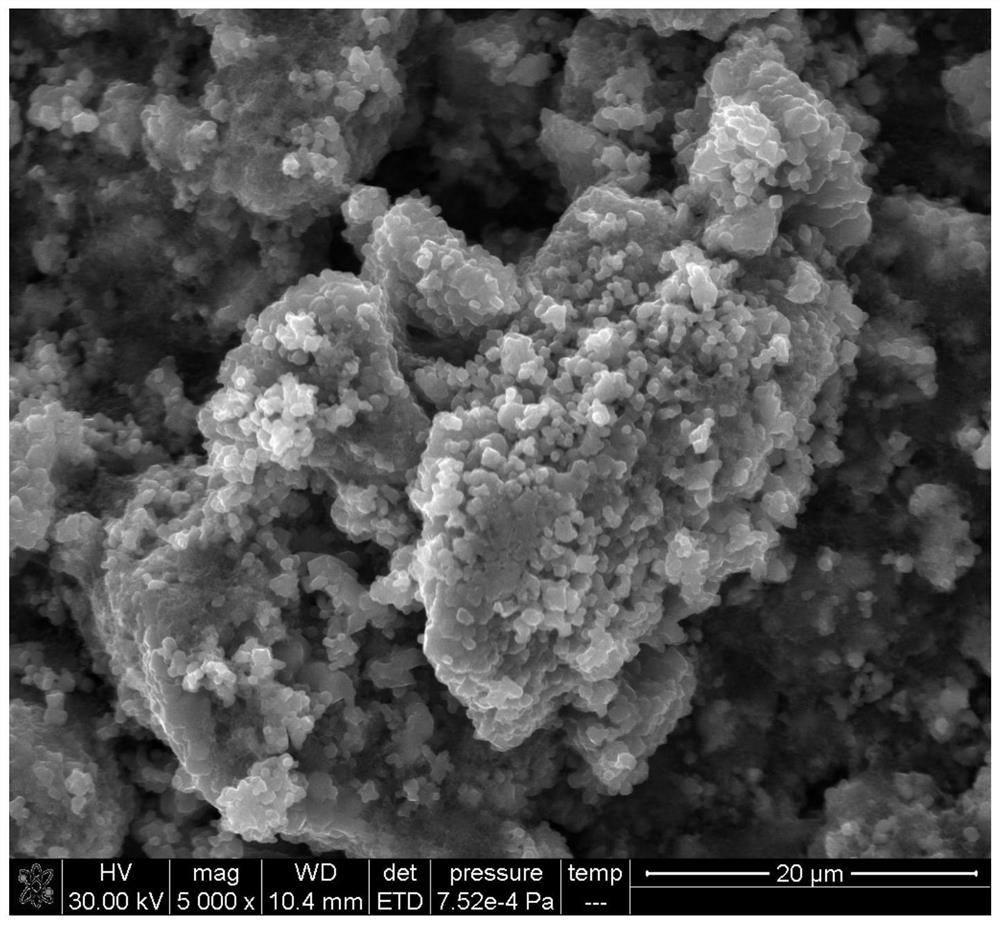

Image

Examples

Embodiment 1

[0034] (1) Mix 50g of raw Ketjen black with 2500g of ultrapure water, feed high-purity oxygen while stirring, and control the flow rate of oxygen feed to 0.5m 3 / h, oxygen time is 3h;

[0035] (2) Put the Ketjen Black after the oxygen treatment into a sand mill for sanding, the sanding medium is zirconia balls, the speed of the sanding is 1800 rpm, and the sanding time is 4 hours, to obtain the Ketjen black pulp material;

[0036] (3) drying the ketjen black slurry obtained in step (2) at a temperature of 80° C. for 12 hours to obtain a ketjen black coarse material;

[0037] (4) Pass through a 200-mesh sieve, and collect the sieved material to obtain an oxidation-modified Ketjen Black conductive agent.

[0038] (5) 30g of binder polytetrafluoroethylene PVDF, 30g of oxidation-modified Ketjen black conductive agent, 940g of active material lithium manganese oxide LMO, nickel-cobalt-manganese ternary material NCM, lithium iron phosphate LFP and lithium nickel manganese oxide LN...

Embodiment 2

[0040] (1) Mix 30g of raw material Ketjen black with 1000g of ultrapure water, feed high-purity oxygen while stirring, and control the flow rate of oxygen feed to 0.2m 3 / h, oxygen time is 5h;

[0041] (2) Put the Ketjen black after the oxygen treatment into a sand mill for sand grinding, the sand grinding medium adopts zirconia balls, the speed of the sand mill is 1000 rpm, and the sand mill time is 5h to obtain Ketjen black pulp material;

[0042] (3) drying the ketjen black slurry obtained in step (2) at a temperature of 50°C for 12 hours to obtain a ketjen black coarse material;

[0043] (4) Pass through a 100-mesh sieve, and collect the sieved material to obtain an oxidation-modified Ketjen Black conductive agent.

[0044] (5) 10g of binder polytetrafluoroethylene PVDF, 20g of oxidation-modified Ketjen black conductive agent, 970g of active material lithium manganese oxide LMO, nickel-cobalt-manganese ternary material NCM, lithium iron phosphate LFP and lithium nickel m...

Embodiment 3

[0046] (1) Mix 50g of raw Ketjen black with 2000g of ultrapure water, feed high-purity oxygen while stirring, and control the flow rate of oxygen feed to 0.8m 3 / h, oxygen time is 2h;

[0047] (2) Put the Ketjen Black after the oxygen treatment into a sand mill for sanding, the sanding medium is zirconia balls, the speed of the sanding is 2500 rpm, and the sanding time is 2 hours to obtain the Ketjen black pulp material;

[0048](3) drying the ketjen black slurry obtained in step (2) at a temperature of 100° C. for 6 hours to obtain a ketjen black coarse material;

[0049] (4) Pass through a 300-mesh sieve, and collect the sieved material to obtain an oxidation-modified Ketjen Black conductive agent.

[0050] (5) 50g of binder polytetrafluoroethylene PVDF, 50g of oxidation-modified Ketjen black conductive agent, 900g of active material lithium manganese oxide LMO, nickel-cobalt-manganese ternary material NCM, lithium iron phosphate LFP and lithium nickel manganese oxide LNMO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com