Calculation Method of Circumferential Stress of Non-isostructural Superposed Valve Plate of Automobile Shock Absorber

A technology of circumferential stress and calculation method, applied in calculation, instrument, special data processing application, etc., can solve the problem that the finite element simulation software cannot give the calculation formula, and cannot satisfy the design and strength calibration of automobile shock absorber and superimposed valve plate Nuclear requirements, circumferential stress calculation does not give a simple and reliable calculation method and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

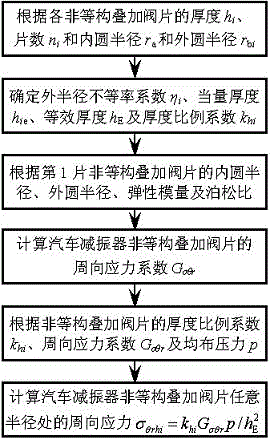

Method used

Image

Examples

Embodiment 1

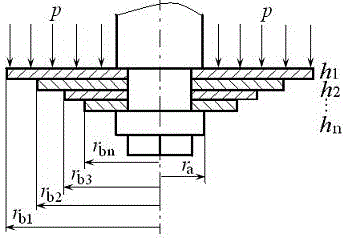

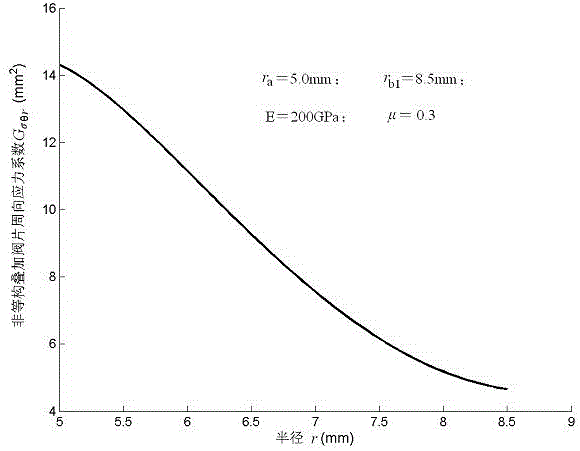

[0048] Example 1: The inner radius r of the non-isostructural superimposed valve plate of an automobile shock absorber a =5.0mm, elastic modulus E=200GPa, Poisson’s ratio μ=0.3, the thickness, number and outer radius of the stacked valve plates are h 1 = 0.25mm, n 1 = 1, r b1 = 8.5 mm; h 2 = 0.20mm, n 2 = 1, r b2 =7.0mm; h 3 = 0.15mm, n 3 = 1, r b3 = 6.0mm; the pressure p = 3.0MPa on the superimposed valve plate, calculate the circumferential stress of the non-isomorphic superimposed valve plate of the automobile shock absorber.

[0049] (1) Determine the outer radius non-uniformity coefficient η of each non-isosteric superimposed valve plate i :

[0050] According to the outer radius r of the non-isostructural superimposed valve plate of the automobile shock absorber b1 =8.5mm, r b2 =7.0mm, r b3 =6.0mm, inner radius r a =5.0mm, determine the outer radius unequal ratio η of each superimposed valve plate i ,which is

[0051] η 1 ...

Embodiment 2

[0077]Example 2: The inner radius r of the non-isostructural superimposed valve plate of a certain automobile shock absorber a = 5.0mm, elastic modulus E = 200GPa, Poisson's ratio μ = 0.3, the thickness, number and outer radius of stacked valve plates are h 1 = 0.3mm, n 1 = 1, r b1 = 8.5 mm; h 2 = 0.20mm, n 2 = 1, r b2 = 7.0mm; the pressure p = 3.0MPa on the non-isomorphic superimposed valve plate, calculate the circumferential stress of the non-isostructic superimposed valve plate of the automobile shock absorber.

[0078] Calculate according to the steps of Example 1, namely:

[0079] (1) Determine the outer radius non-uniformity coefficient η of each non-isosteric superimposed valve plate i :

[0080] According to the outer radius r of the non-isostructural superimposed valve plate of the automobile shock absorber b1 =8.5mm, r b2 =7.0mm, inner radius r a =5.0mm, determine the outer radius unequal ratio η of each superimposed valve plate i ,which is

[0081] ...

Embodiment 3

[0098] Example 3: The inner radius r of the non-isostructural superimposed valve plate of a certain automobile shock absorber a =5.0mm, elastic modulus E=200GPa, Poisson’s ratio μ=0.3, the thickness, number and outer radius of the stacked valve plates are h 1 = 0.2mm, n 1 = 1, r b1 = 8.5 mm; h 2 = 0.15mm, n 2 = 1, r b2 = 7.0mm, the pressure p = 2.5MPa on the non-isomorphic superimposed valve plate, calculate the circumferential stress of the non-isomorphic superimposed valve plate of the automobile shock absorber.

[0099] Calculate according to the steps of Example 1, namely:

[0100] (1) Determine the outer radius non-uniformity coefficient η of each non-isosteric superimposed valve plate i :

[0101] According to the outer radius r of the non-isostructural superimposed valve plate of the automobile shock absorber b1 =8.5mm, r b2 =7.0mm, inner radius r a =5.0mm, determine the outer radius unequal ratio η of each superimposed valve plate i ,which is

[0102] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com