Arc extinguish chamber structure of disconnector

A technology of arc extinguishing chamber and circuit breaker, which is applied in the direction of circuits, electrical components, electric switches, etc. It can solve the problems of metal particles easily returning to the arc extinguishing chamber, so as to improve the effect of arc extinguishing, prevent ejection and reduce density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

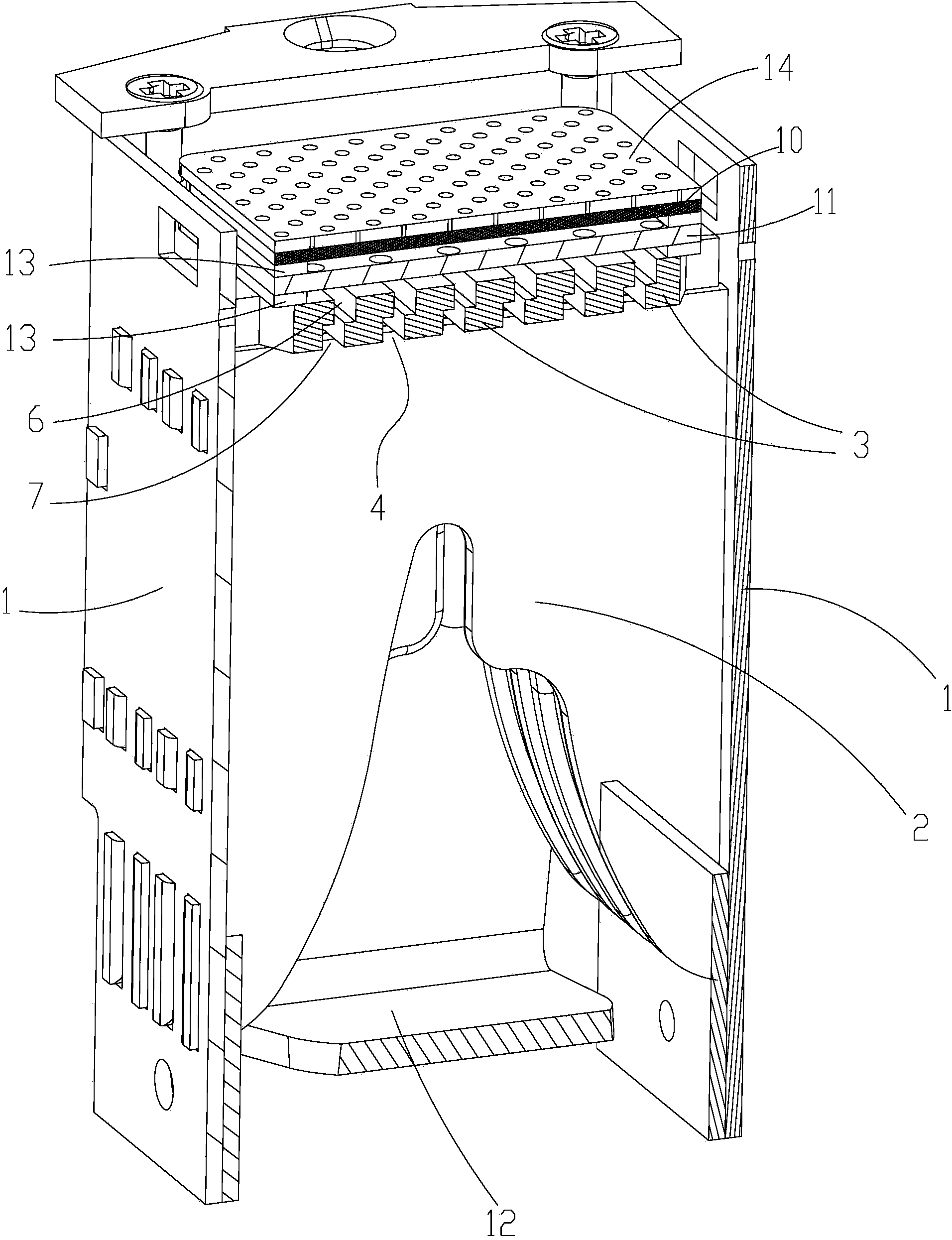

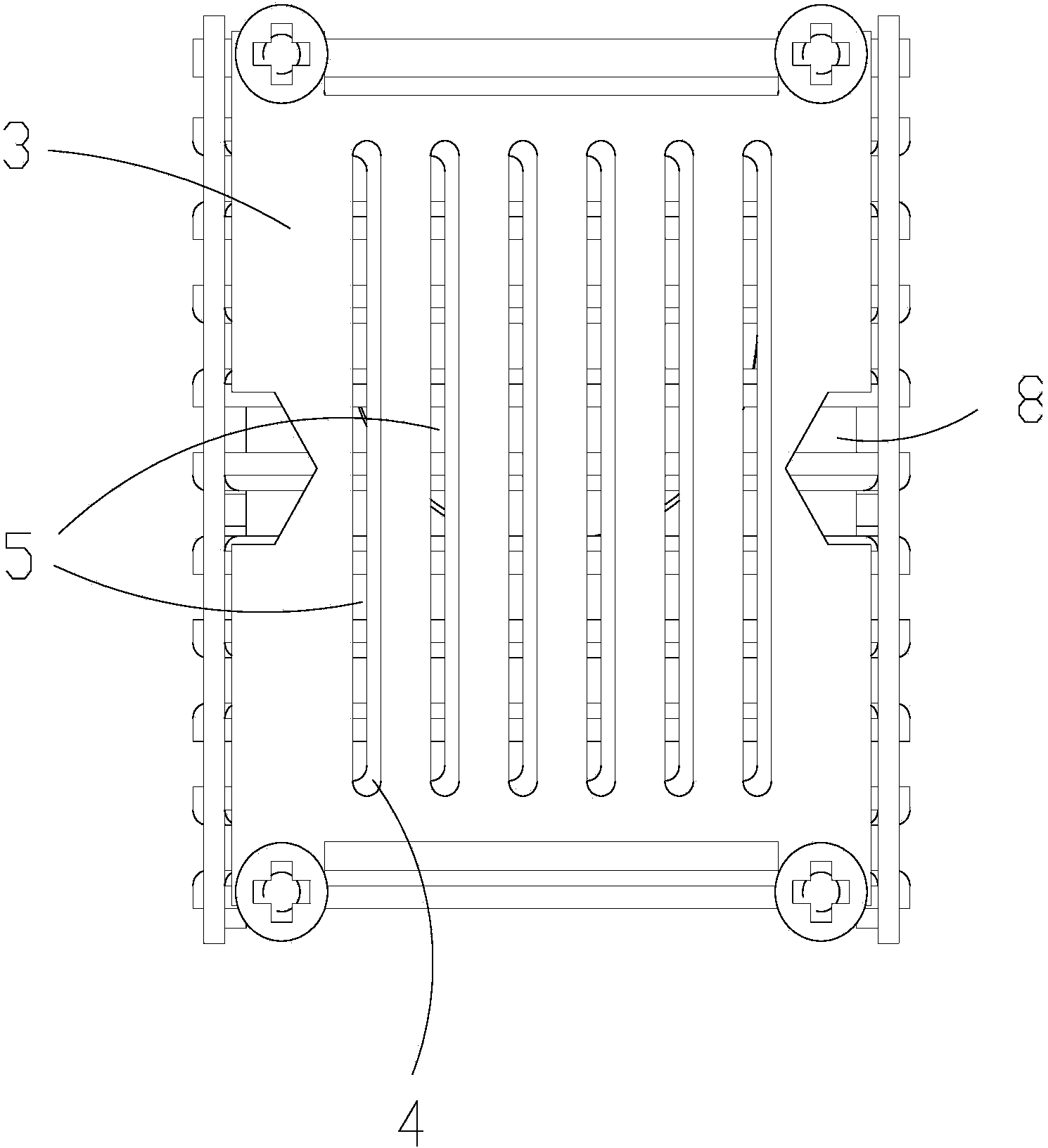

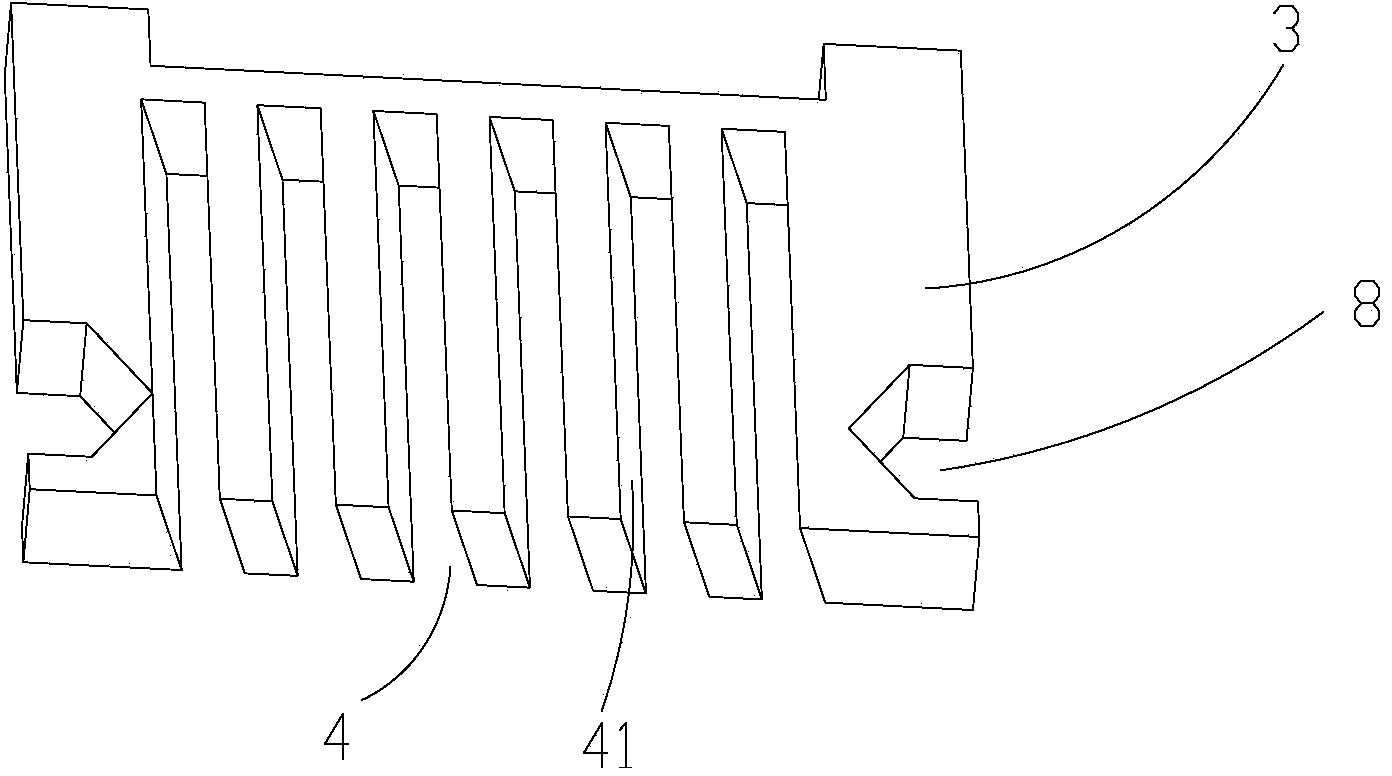

[0025] The structure of the arc extinguishing chamber of the circuit breaker provided by the specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as figure 1 with 2 As shown, the arc extinguishing chamber structure of the circuit breaker includes a pair of arc extinguishing walls 1 opposite to each other, a plurality of arc extinguishing grids 2 arranged between the arc extinguishing walls 1 and spaced parallel to each other, and the arc extinguishing grid The insulating grid 3 above the sheet 2 is characterized in that the insulating grid 3 is formed with a plurality of extended non-straight-through exhaust slits 4, and the exhaust slits 4 are in phase with the arc extinguishing grids 2 arranged in parallel at intervals. Cross setting, that is, mutually staggered setting to form a plurality of exhaust holes 5 for the discharge of arc free steam. At the same time of discharge, it can block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com