Multi-directional pay-off block

A technology of pay-off pulley and side plate, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the workload of construction personnel, affecting the safe and stable operation of the power system, and heating of contacts, so as to avoid wire jamming or damage to the insulation layer of wires , reduce potential safety hazards, and avoid disconnection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

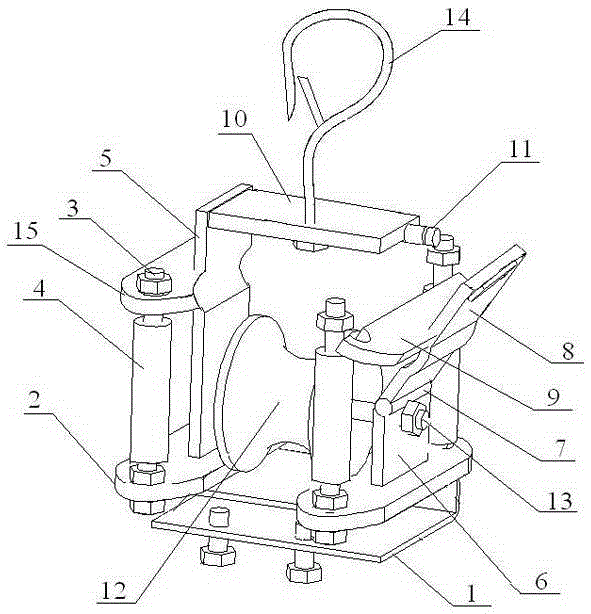

[0023] Multi-directional pay-off block, its structure is as follows figure 1 Shown, comprise base 1, support, roller 12 and nylon steering bar 4.

[0024] The base 1 is a U-shaped structure placed horizontally, and the lower bottom plate of the base 1 is provided with matching bolt holes and bolts for fixing the base 1 on a pole tower or a cross arm.

[0025] The support includes a lower fixing plate 2, a beam 10 and two side plates. In this embodiment, the lower fixing plate adopts a strip structure, and there are two pieces in total. The two lower fixing plates 2 are welded side by side on the top plate of the base 1. Both ends of the lower fixing plate 2 are provided with bolt holes. Four iron pins 3 Bolt holes are respectively vertically arranged at the two ends of the two lower fixing plates 2, both ends of the iron pin 3 are provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com