rolling stock

A technology for railway vehicles and vehicle lengths, applied in the direction of railway car bodies, railway car body parts, buffer cars, etc., can solve the problems of indoor space compression, unsatisfactory, heavy repairs, etc., and achieve the effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments according to the present invention will be described with reference to the drawings. Hereinafter, the same reference numerals are assigned to the same or corresponding elements throughout the drawings, and repeated descriptions will be omitted.

[0027] (first embodiment)

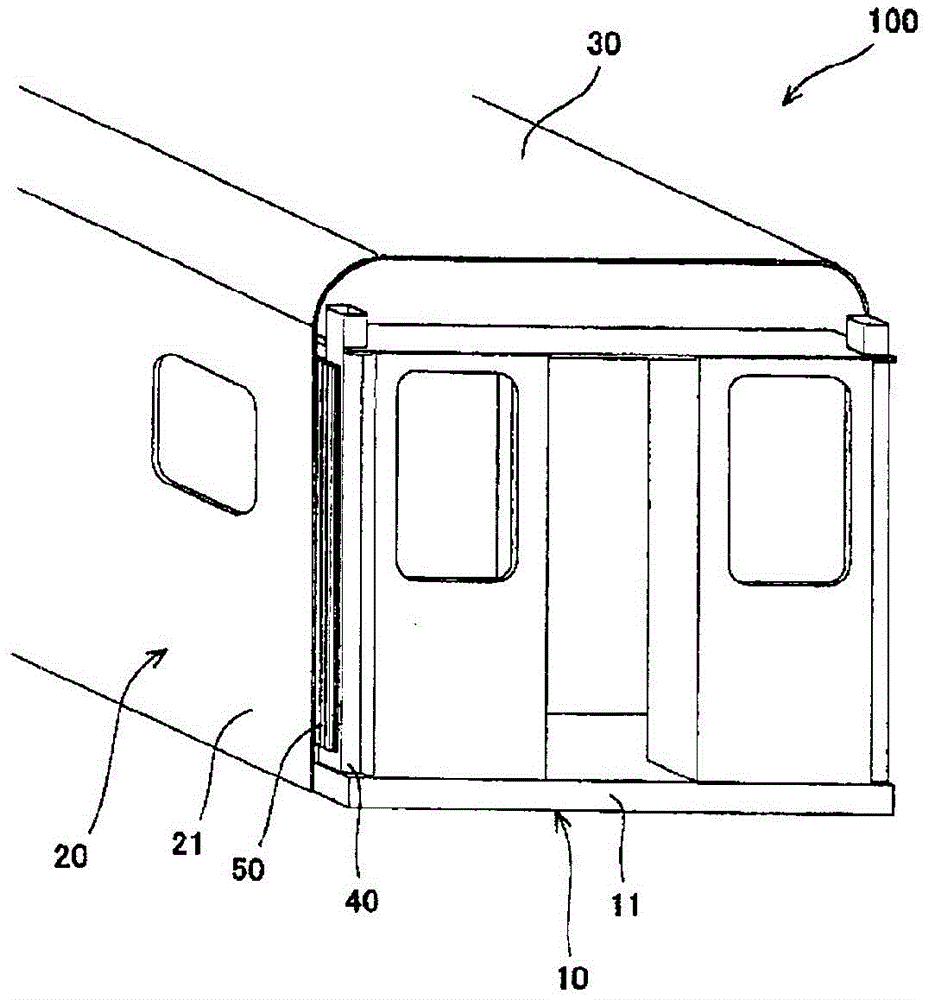

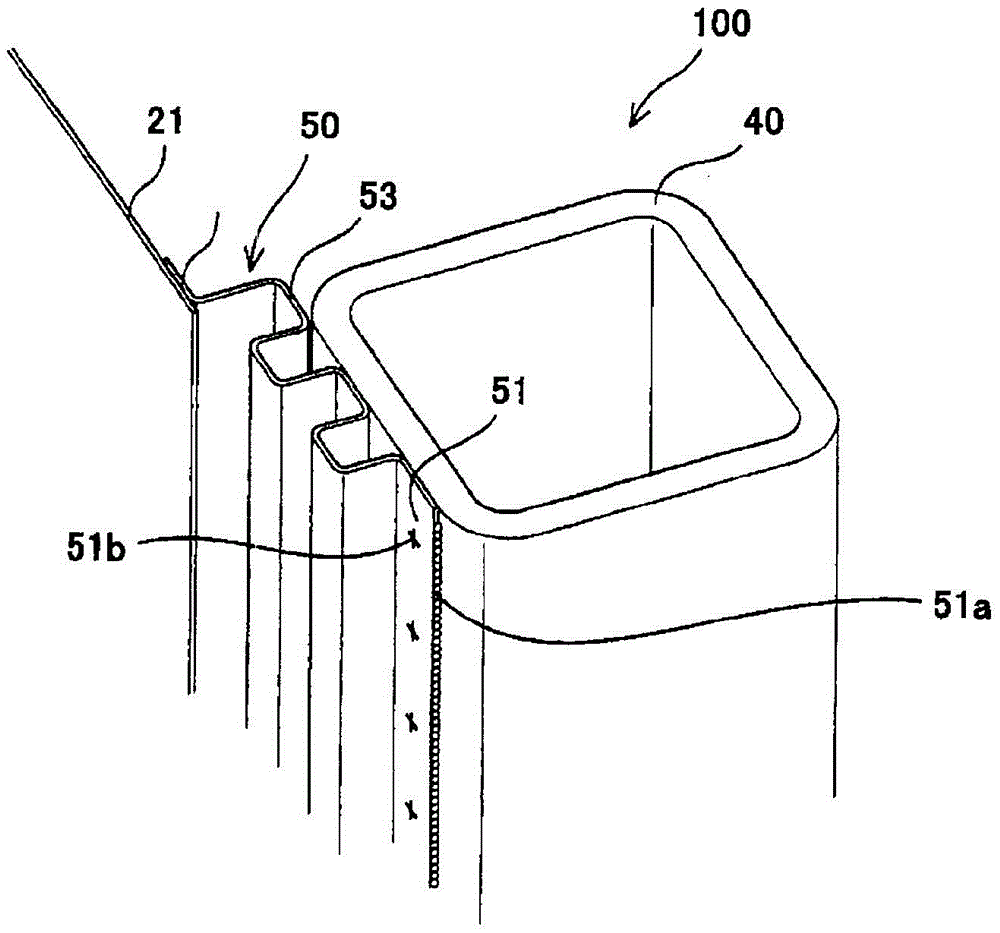

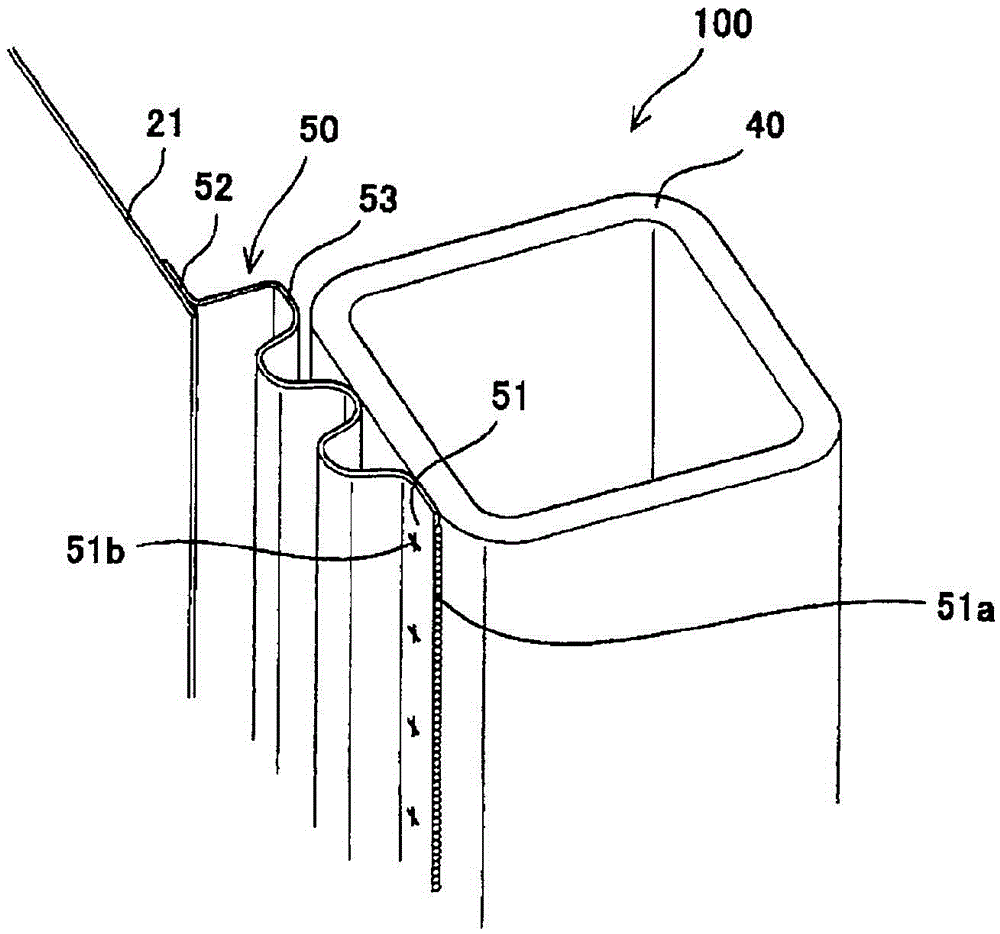

[0028] First, refer to Figure 1 to Figure 6 The railway vehicle 100 according to the first embodiment of the present invention will be described. figure 1 It is a perspective view of the railway vehicle 100 according to this embodiment, and is a view of a state where an end outer panel is removed. Such as figure 1 As shown, the railway vehicle 100 according to this embodiment has a basic structure of an underframe 10 having end beams 11 at ends in the vehicle longitudinal direction (vehicle longitudinal direction), side structures 20 , and roof structures 30 . Moreover, the railroad vehicle 100 is equipped with the side outer panel 21, the corner post 40, and the interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com