Back iron and method for manufacturing back iron

A technology of back iron and metal strip, applied in the back iron of motor rotor or stator, electromagnetic back iron core, in the field of manufacturing such back iron, it can solve the problems of inaccuracy and improve the use characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

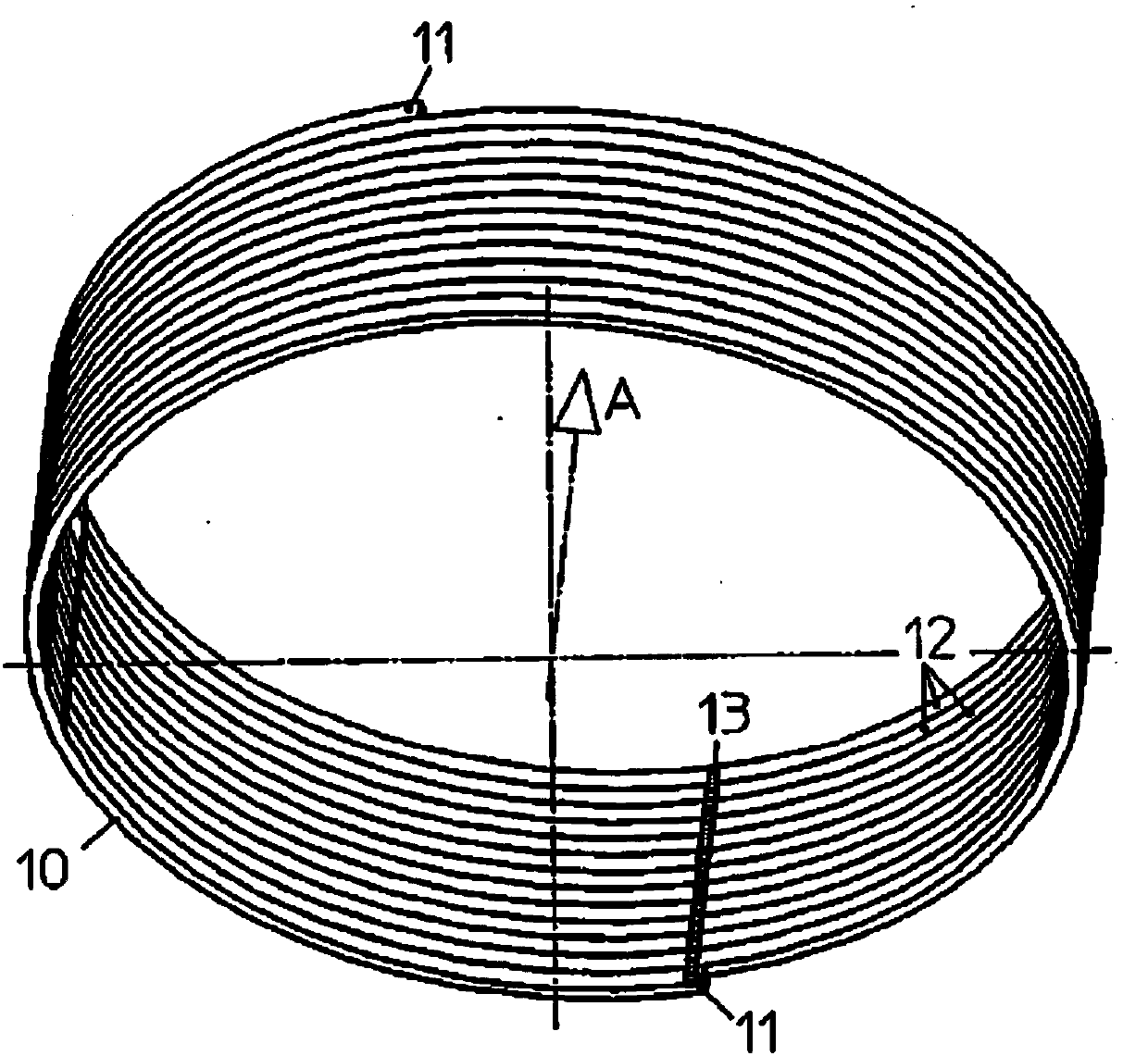

[0028] figure 1 A back iron 10 is shown, ie the electromagnetic back iron core, as it is used for the stator or rotor of an electric machine. In this case, layers 12 of metal strip 40 are wound and form a cylindrical body which encloses an interior. The ends 11 of the metal strip 40 are arranged offset by 180°, so that the end sides of the back iron 10 running transversely to the back iron axial direction A are approximately planarly parallel to one another.

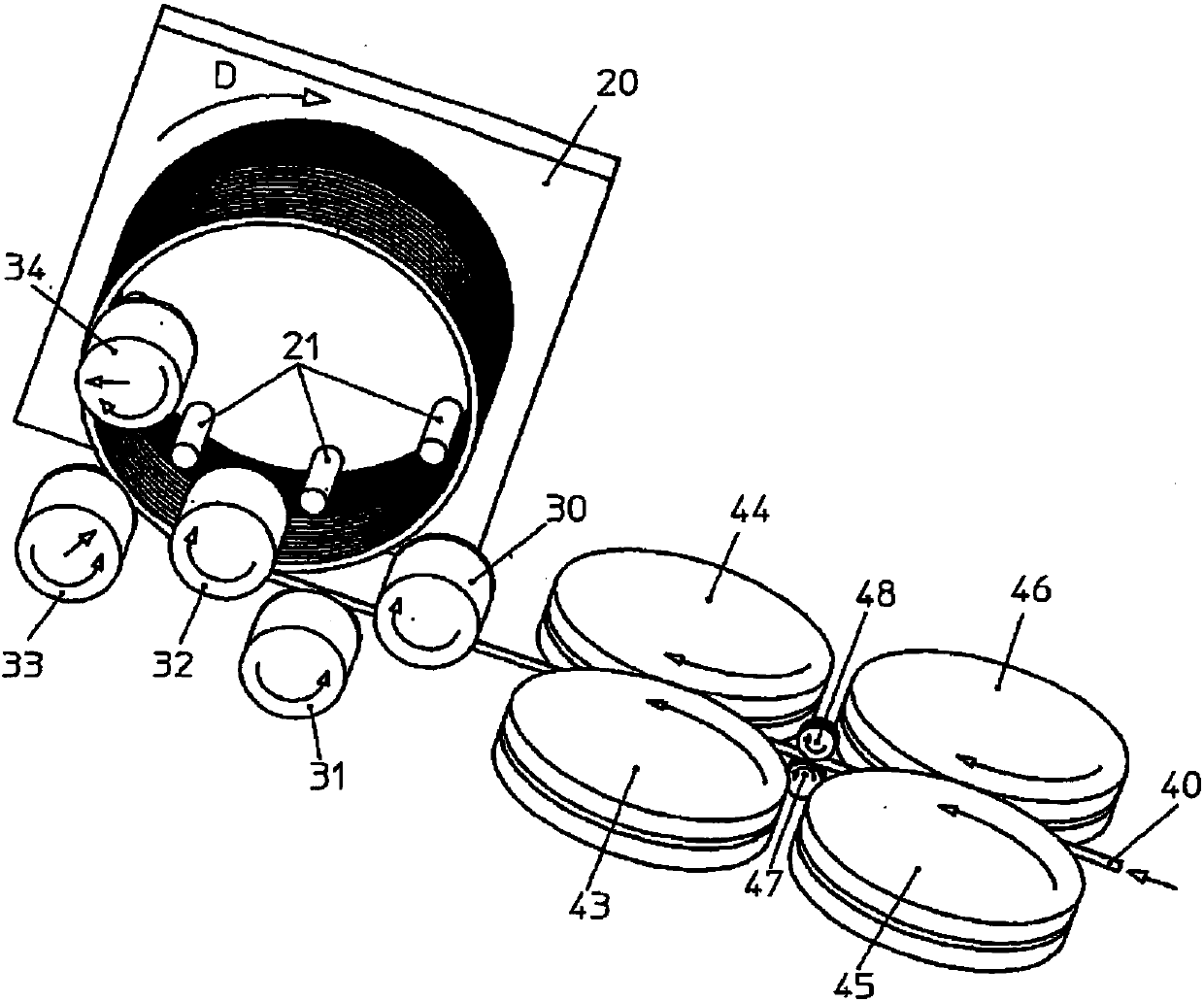

[0029] In order to manufacture the back iron 10, a metal strip 40 is used, such as figure 2 shown is supplied to the winding device.

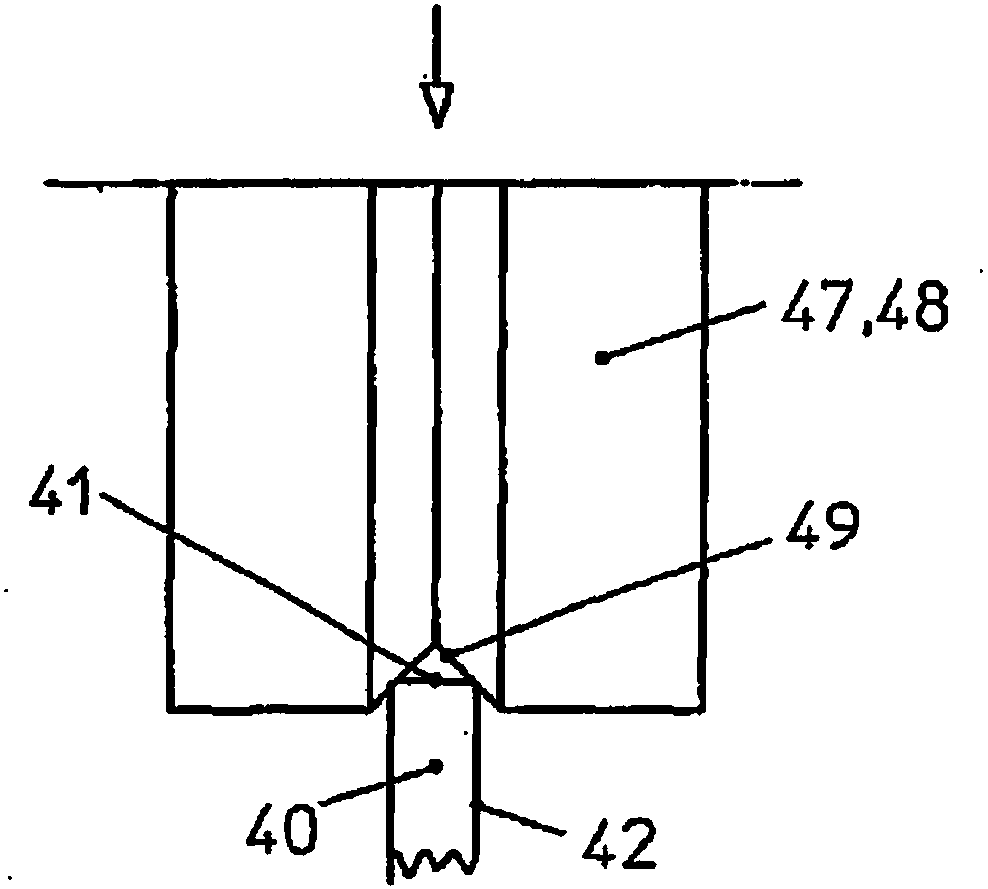

[0030] Figure 4 A cross-sectional view of the metal strip 40 is shown. as from Figure 4 It can be seen that the metal strip 40 has a rectangular cross-section forming vertical and horizontal axes H, Q. FIG. The cross-section is delimited by longitudinal sides 42 and transverse sides 41 . Advantageously, a sheet metal strip, particularly preferably a slotted sheet metal sheet, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com