Flash welding method for dissimilar metal

A technology of dissimilar metals and welding methods, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve problems such as overburning of copper pipes, occurrence of dirty, copper and iron pipes that cannot be welded, and improve welding quality , good self-fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

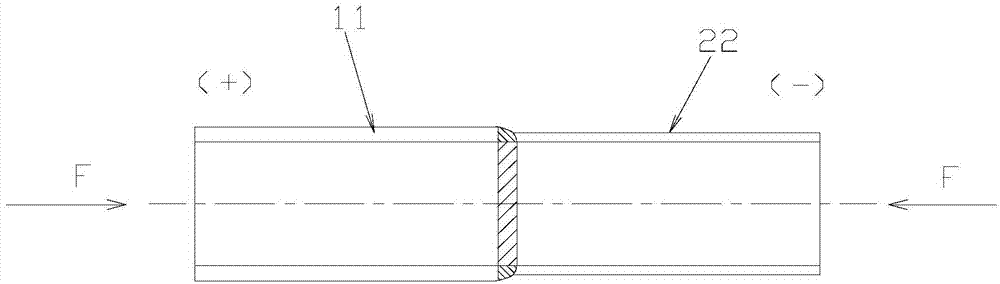

[0028] Such as figure 1 As shown, this embodiment is the butt welding of the copper pipe 11 and the iron pipe 22.

[0029] There is no preheating of the pipe before welding, but the thickness of the iron pipe 22 is about 20%-50% less than that of the copper pipe 11. At the beginning of welding, after the copper tube 11 and the iron tube 22 are assembled in the clamps of the secondary connection of the welding transformer, a large current is applied to them, and the copper tube 11 and the iron tube 22 quickly contact each other and form a closed circuit. Open the circuit to form an intermittent flash, which causes the butt end to generate high heat until the butt end is melted; when the length of the butt end being melted reaches the set melting length, the upsetting force is quickly applied to complete the welding of the copper pipe 11 and the iron pipe 22.

Embodiment 2

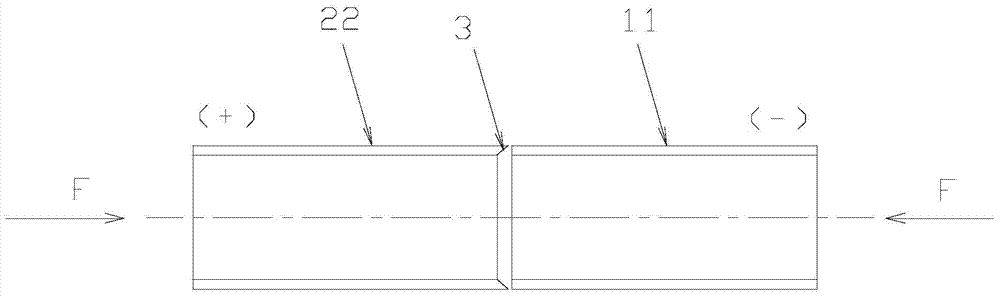

[0031] Such as figure 2 As shown, this embodiment is the butt welding of the copper pipe 11 and the iron pipe 22.

[0032] The iron pipe 22 and the copper pipe 11 have the same thickness, but the joint 3 of the iron pipe 22 is cut into a bevel, so that the part that needs to be melted is about 1 / 3 less than that of the copper pipe 22. No preheating of the pipe before welding. The welding operation is the same as in Example 1.

Embodiment 3

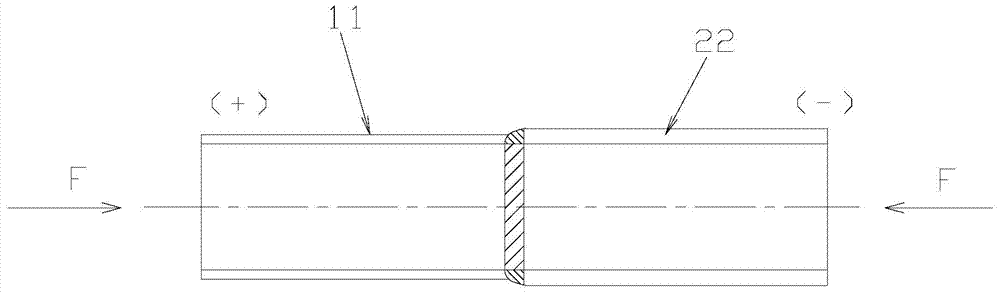

[0034] Such as image 3 As shown, in this embodiment, the copper tube 11 and the iron tube 22 are butt welded.

[0035] The thickness of the iron pipe 22 is about 1 / 3 thicker than that of the copper pipe 11. The iron pipe 22 is preheated to 950±50°C before welding. The welding operation is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com