Welding methods for dissimilar metals

A technology of dissimilar metals and welding methods, used in welding equipment, metal processing equipment, welding/welding/cutting items, etc. The effect of smooth and bright, improved welding strength and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

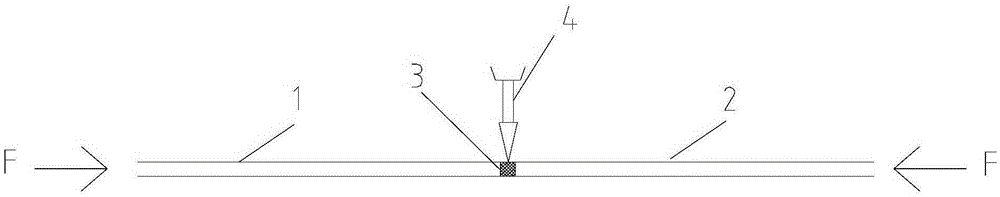

[0042] Such as figure 1 As shown, in this embodiment, the copper plate 1 and the iron plate 2 are butt welded by argon arc welding, and the thickness of the two plates is the same.

[0043] Preheat the iron plate 2 to 500±50°C before welding, so that Q’ 高熔点金属 -△Q is equal to 0.90Q’ 低熔点金属 ~1.1Q' 低熔点金属 . The edges of the copper plate 1 and the iron plate 2 are butted in contact to form a weld 3 , which does not need solder. When the edges of the copper plate 1 and the iron plate 2 are butted, apply a force F in opposite directions on the other side of the copper plate 1 and the other side of the iron plate 2, so that the edges of the copper plate 1 and the iron plate 2 are welded during the entire welding process. Stay in touch. Then determine the relative position of welding seam 3 and welding torch nozzle 4, heat can be evenly distributed to copper plate 1 and iron plate 2 in this embodiment, the heating equipment that adopts is a single welding torch, welding torch nozzl...

Embodiment 2

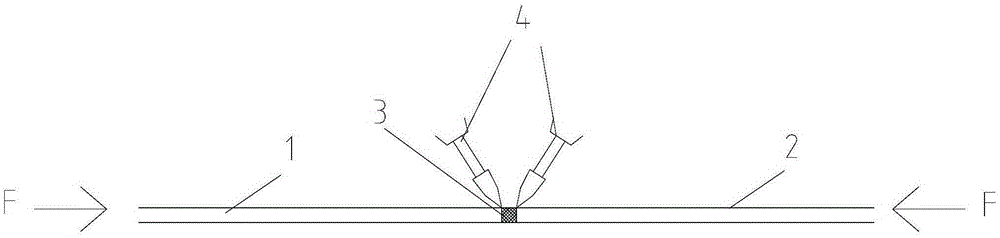

[0045] Such as figure 2 As shown, in this embodiment, the copper plate 1 and the iron plate 2 are butt welded by argon arc welding, and the thickness of the two plates is the same.

[0046] Preheat the iron plate 2 to 300±50°C before welding, so that Q’ 高熔点金属 -△Q greater than 1.1Q’ 低熔点金属 . The edges of the copper plate 1 and the iron plate 2 are butt-contacted to form a weld 3 , and no solder is needed for the weld 3 . When the edges of the copper plate 1 and the iron plate 2 are butted, apply a force F in opposite directions on the other side of the copper plate 1 and the other side of the iron plate 2, so that the edges of the copper plate 1 and the iron plate 2 are welded during the entire welding process. Stay in touch. Then determine the relative position of welding seam 3 and welding torch nozzle 4, the heating equipment that adopts in the present embodiment is double welding torch, wherein the corresponding processing copper plate 1 of welding torch nozzle 4 that o...

Embodiment 3

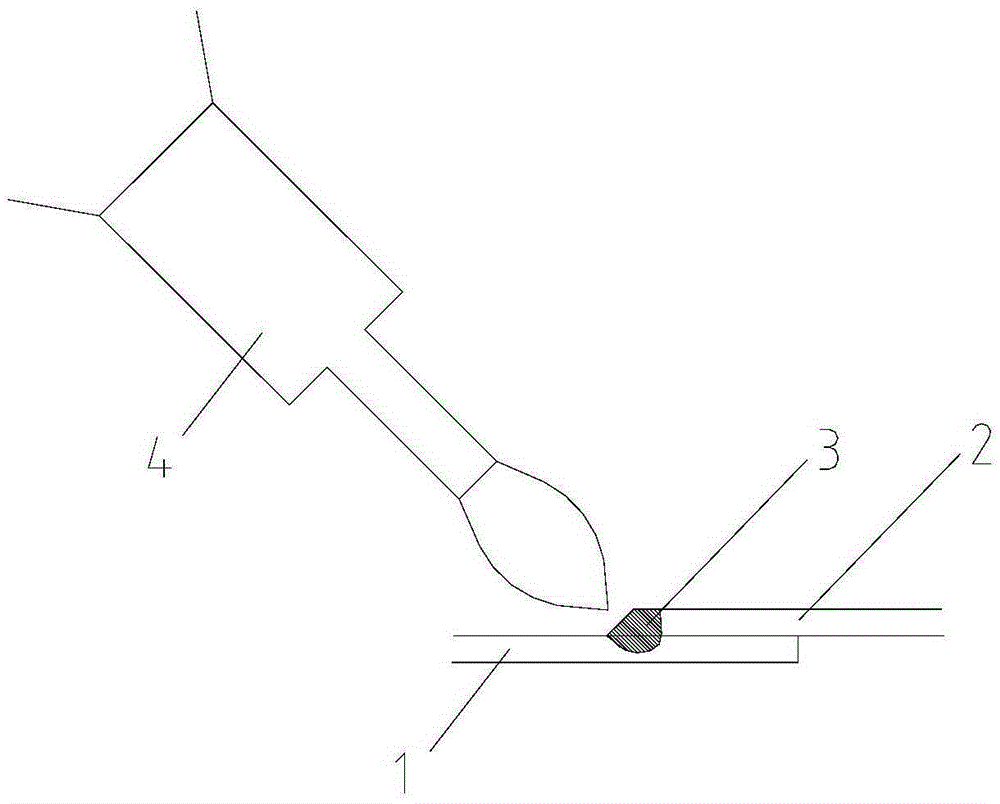

[0048] Such as image 3 As shown, in this embodiment, the copper plate 1 and the iron plate 2 are lap welded by argon arc welding, and the thickness of the two plates is the same.

[0049] Preheat the iron plate 2 to 300±50°C before welding, so that Q’ 高熔点金属 -△Q greater than 1.1Q’ 低熔点金属 . The edges of the copper plate 1 and the iron plate 2 are overlapped to form a welding seam 3 in overlapping contact, and the welding seam 3 does not need solder. Then determine the relative position of welding seam 3 and welding torch nozzle 4, the heat supply equipment that adopts in the present embodiment is single welding torch, welding torch nozzle 4 points to welding seam 3 and the heating zone shifts toward iron plate 2 direction, makes iron plate 2 or get The heat is about 1.2 times the heat obtained by the copper plate 1, and the angle between the central axis of the welding torch nozzle 4 and the overlapping plane is 45°, so that when welding, the position of the iron plate 2 near...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com