Welding method of dissimilar metal sheets

A technology of dissimilar metals and welding methods, applied in welding equipment, metal processing, welding equipment, etc., can solve the problems of rising material cost, low welding strength, limited application, etc., to improve welding strength, improve welding quality, and smooth welding joints. bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

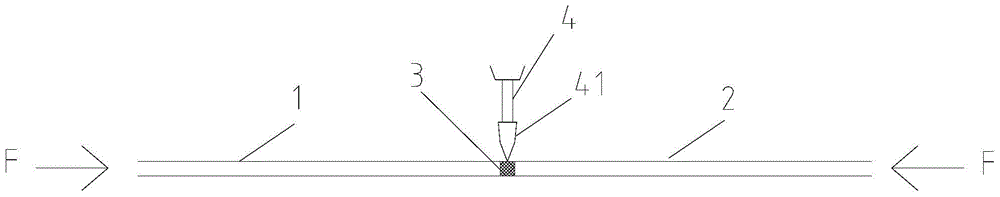

[0025] Such as figure 1 As shown, this embodiment is the butt welding of the copper plate 1 and the iron plate 2, and the thickness of the two plates is the same.

[0026] Before welding, the edges of the copper plate 1 and the iron plate 2 are abutted in contact to form a weld 3, which does not need solder. When the edges of the copper plate 1 and the iron plate 2 are butted, apply a force F in opposite directions on the other side of the copper plate 1 and the other side of the iron plate 2, so that the edges of the copper plate 1 and the iron plate 2 are welded during the entire welding process. Stay in touch. Then determine the relative position of the welding seam 3 and the welding torch nozzle 4, the heating equipment adopted in this embodiment is a single welding torch, so that the welding torch nozzle 4 is shifted toward the iron plate 2 direction. The offset is determined according to the melting point temperature of the two metals, and more heat is distributed to t...

Embodiment 2

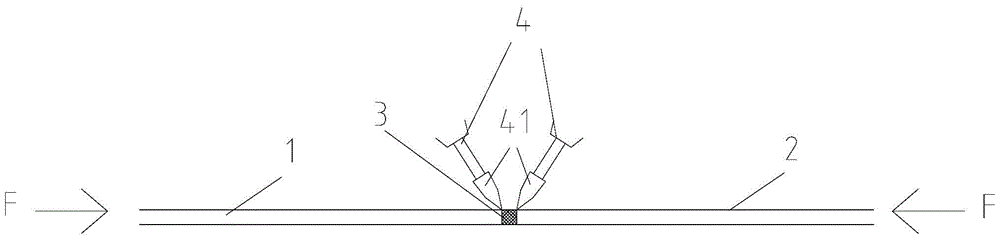

[0028] Such as figure 2 As shown, this embodiment is the butt welding of the copper plate 1 and the iron plate 2, and the thickness of the two plates is the same.

[0029] Before welding, the edges of the copper plate 1 and the iron plate 2 are abutted in contact to form a weld 3, and the weld 3 does not need solder. When the edges of the copper plate 1 and the iron plate 2 are butted, apply a force F in opposite directions on the other side of the copper plate 1 and the other side of the iron plate 2, so that the edges of the copper plate 1 and the iron plate 2 are welded during the entire welding process. Stay in touch. Then determine the relative position of welding seam 3 and welding torch nozzle 4, the heating equipment that adopts in the present embodiment is double welding torch, wherein the welding torch nozzle 4 of output higher heat is corresponding to handle iron plate 2, and the welding torch nozzle 4 of output lower heat is corresponding The copper plate 1 is p...

Embodiment 3

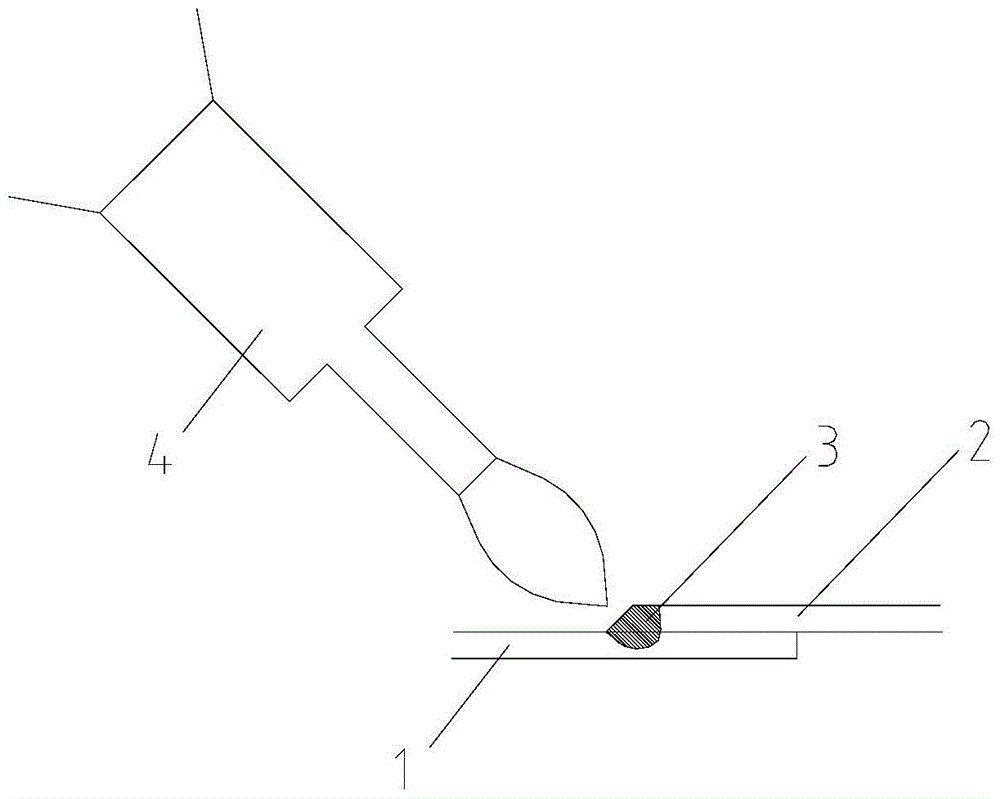

[0031] Such as image 3 As shown, this embodiment is lap welding of copper plate 1 and iron plate 2, and the thickness of the two plates is the same.

[0032] Before welding, the edges of the copper plate 1 and the iron plate 2 overlap, and the overlapping contact forms a weld 3, and the weld 3 does not need solder. Then determine the relative position of welding seam 3 and welding torch nozzle 4, the heating equipment that adopts in the present embodiment is a single welding torch, welding torch nozzle 4 points to welding seam 3 and the heating zone shifts toward iron plate 2 directions, the central axis of welding torch nozzle 4 The included angle with the overlapping plane is 45°, so that during welding, the iron plate 2 close to the welding torch needs to form a mutual melting zone, which is completely or partially melted, and the copper plate 1 is partially melted at a position where a mutual melting zone needs to be formed, and the two plates pass through Self-fluxing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com