Side-blown synchronous scrubbing windscreen wiper reversing by double wiper blade shafts

A technology of wiper and wiper blade, which is applied in the field of automobile wiper and wiper, which can solve the problems that water spraying and brushing cannot be synchronized, and achieve the effect of high wiping efficiency and saving washing liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

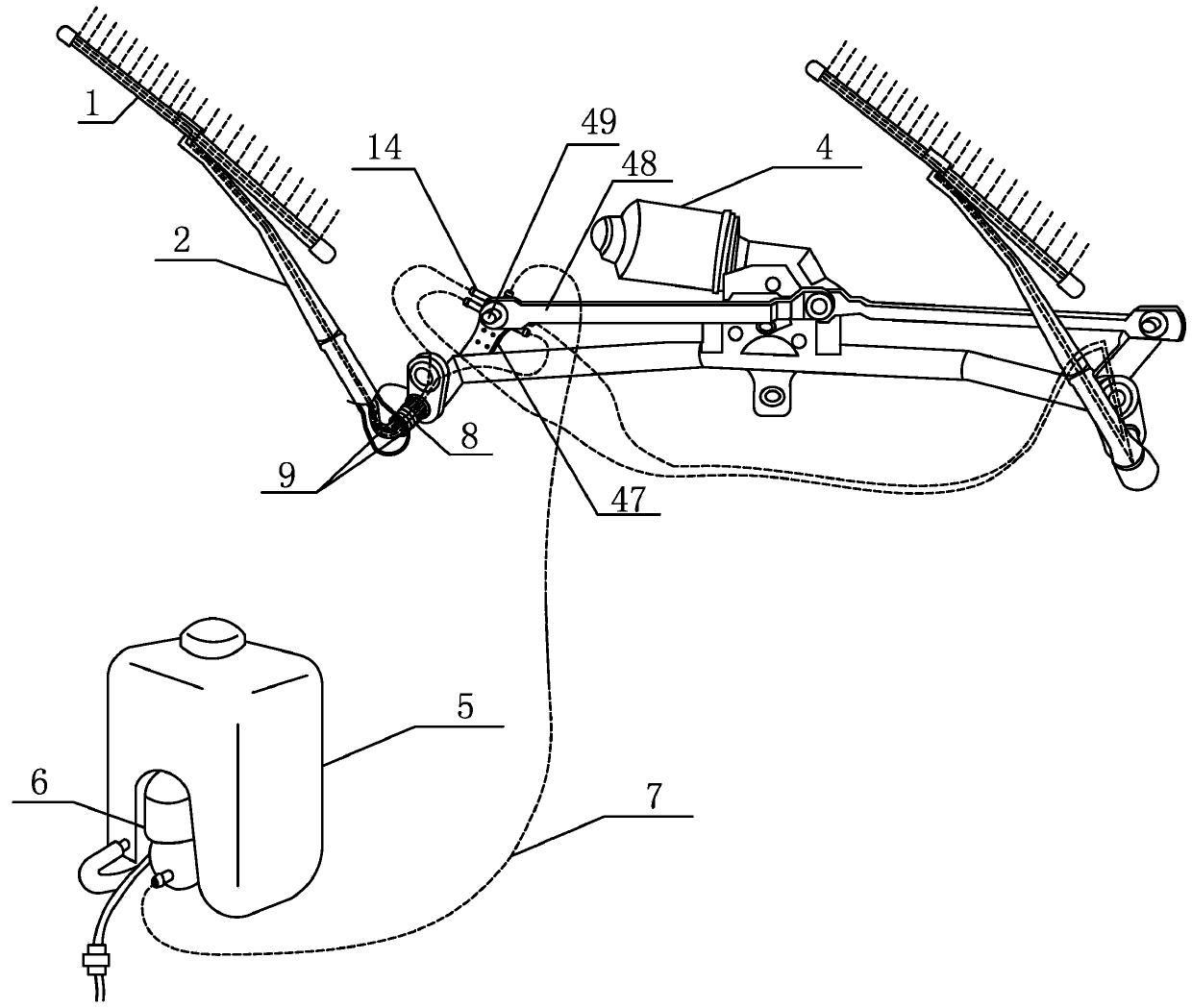

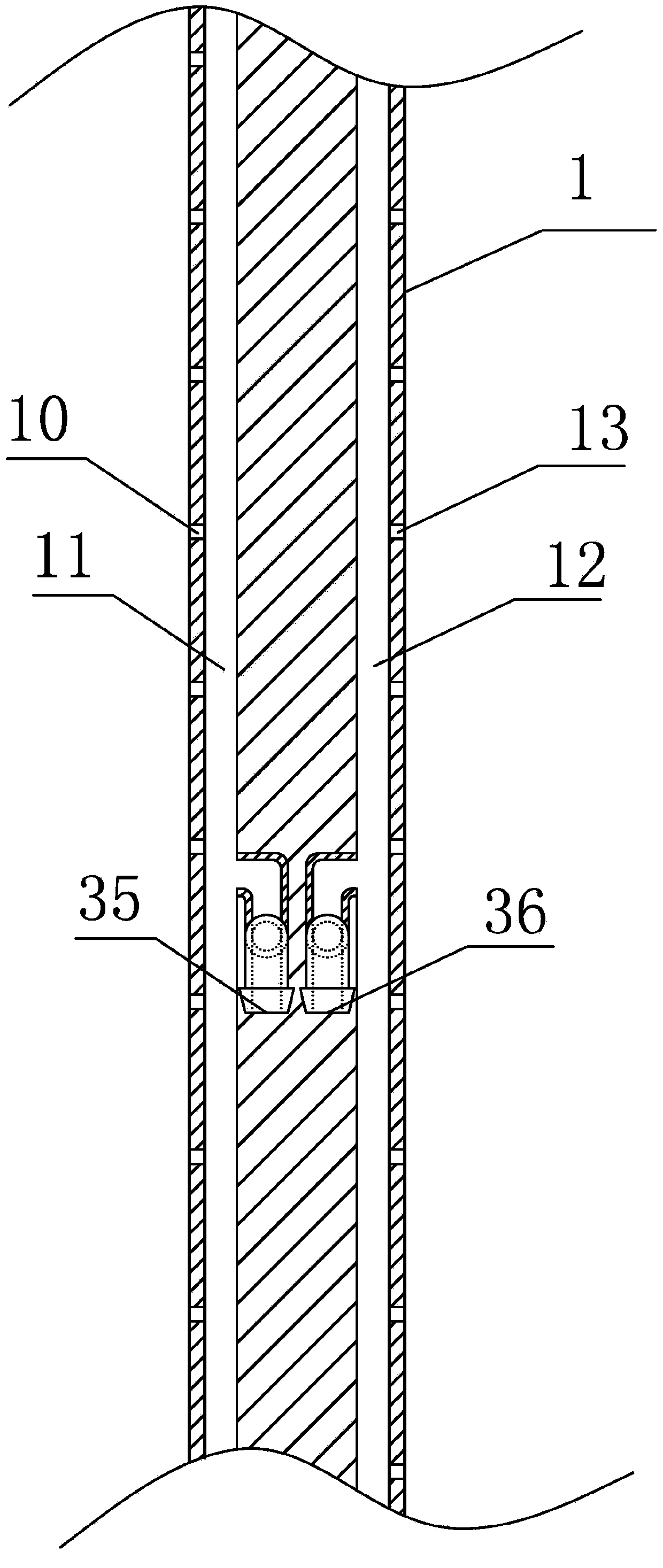

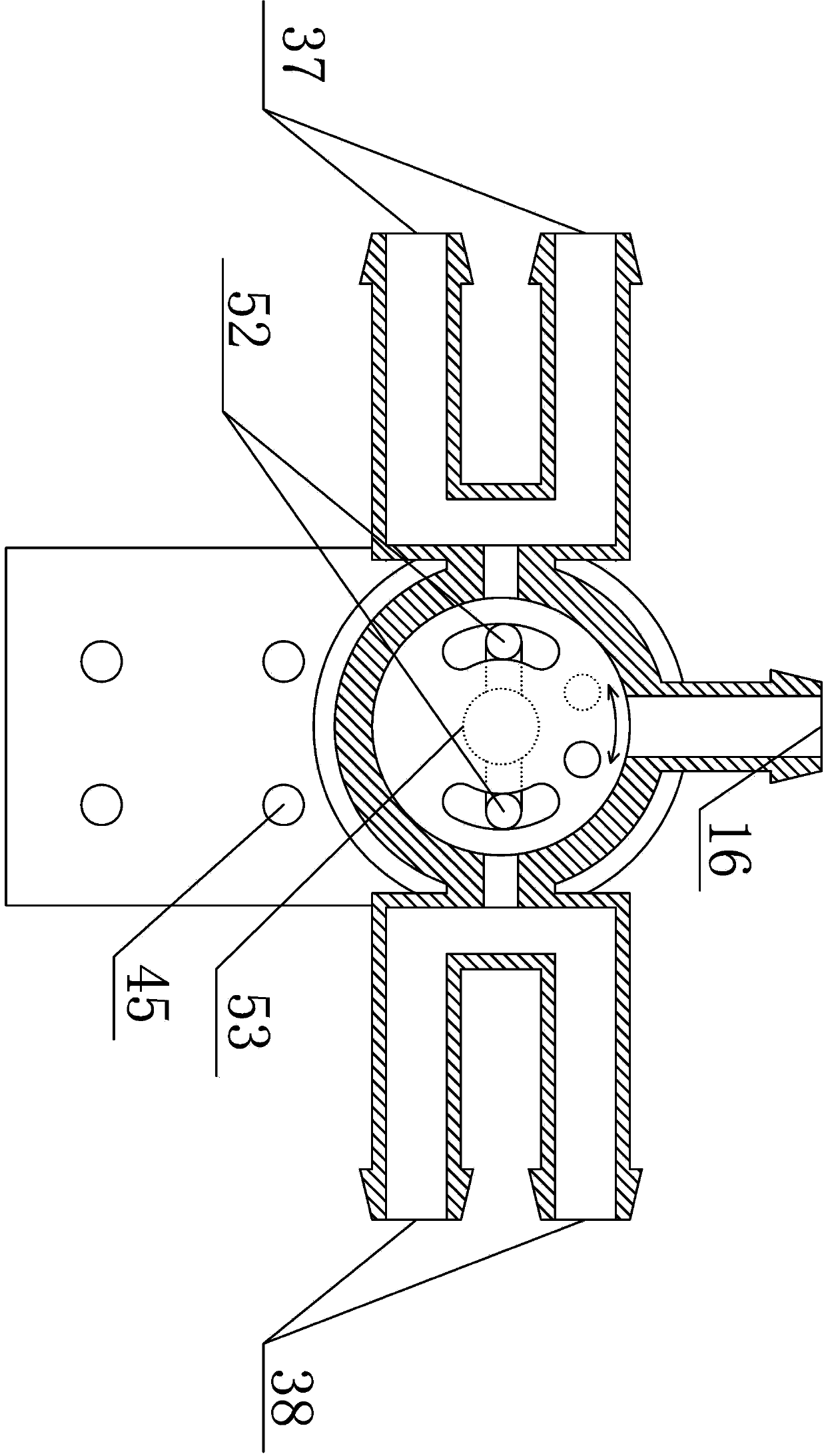

[0019] Figure 1-Figure 7 In the embodiment, it includes a brush head (1), a wiper motor (4), a washing pot (5), a washing water pump (6) and a water supply pipe (7). The left water channel of the brush head (11) and the right water channel of the brush head (12) are respectively provided with a plurality of left nozzles of the brush head (10) and right nozzles of the brush head (13) on the outside of the left and right water channels. The tube is the left water supply pipe (33) and the right water supply pipe (34) extending down the brush arm (2), passing through the hollow brush arm power shaft (8) and respectively connecting with the power shaft drive arm (47). The water supply port of the reversing valve (14) is the water supply port (37) of the left channel of the reversing valve and the water supply port (38) of the right water channel of the reversing valve. One end of the water supply pipe (7) of the reversing valve is connected to the water inlet of the reversing valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com