A Circular Transmission Mechanism and Circular Transmission Method for Tunnel Furnace Tray

A technology of circular transmission and tunnel furnace, which is applied in the direction of conveyor, transportation and packaging, etc., and can solve the problems of failure to realize circulation and inconvenient automatic production of products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

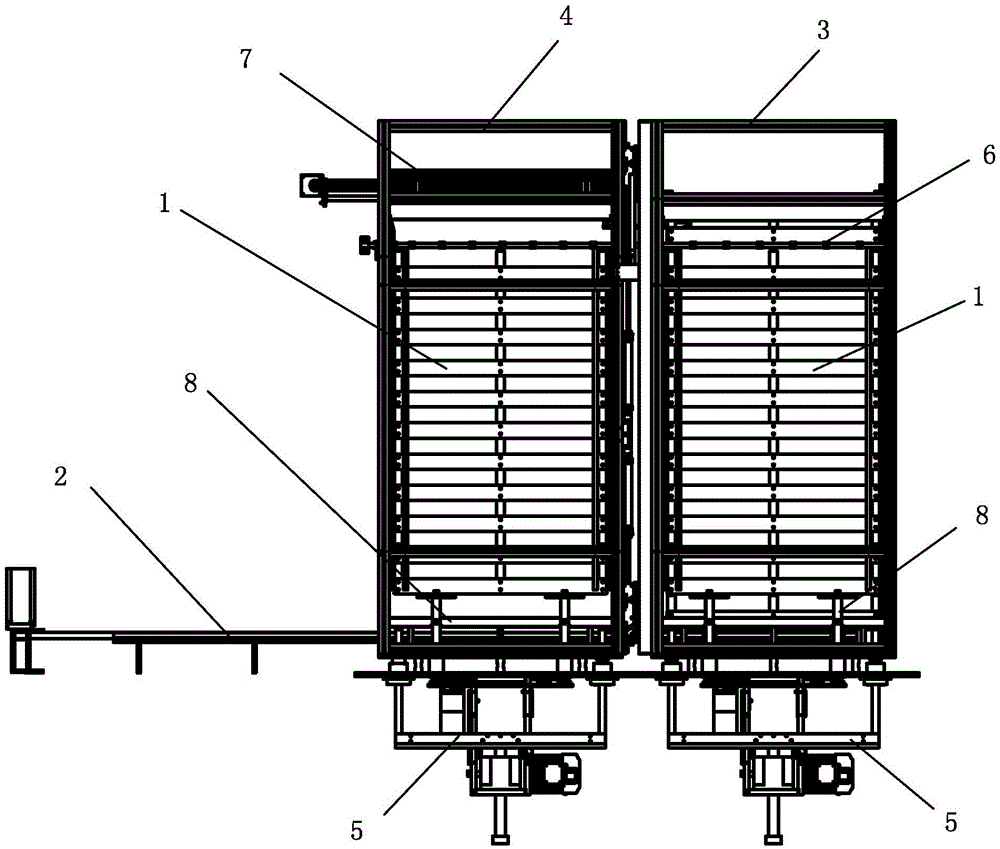

[0056] see Figure 1 to Figure 15 As shown, a kind of tunnel furnace tray circulating transmission mechanism of the present invention includes:

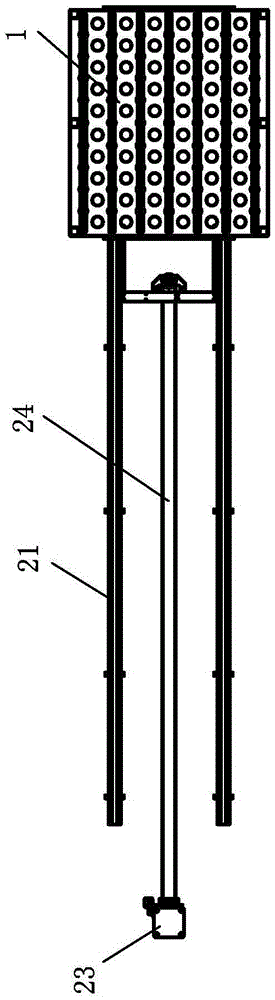

[0057] Carrier 1;

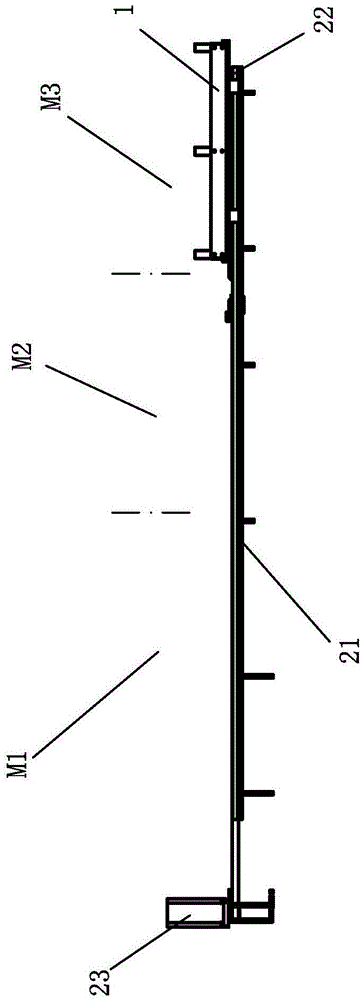

[0058] A horizontal reciprocating mechanism 2 has a horizontal track 21 and a carrier plate 22 capable of reciprocating movement on the horizontal track, and the horizontal track is sequentially provided with a first position M1, a second position M2 and a third position M3;

[0059] A drying box 3 is installed in a position suitable for the third position M3 of the horizontal track, the drying box 3 is provided with a drying chamber along the vertical, the third position M3 of the horizontal track extends into the bottom of the drying chamber;

[0060] A cooling box 4 is installed in a position suitable for the second position M2 of the horizontal track, the cooling box 4 is provided with a vertical cooling chamber, and the second position M2 of the horizontal track extends into the the bottom of the cooling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com