Battery arrangement structure and arrangement method

A battery and battery compartment technology, applied in the direction of structural parts, assembled battery machines, battery pack components, etc., can solve the problems of mutual influence of batteries, inability to store multiple batteries well, safety accidents, etc., and achieve unsafe and Compact and reliable storage, improving space utilization, ensuring stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

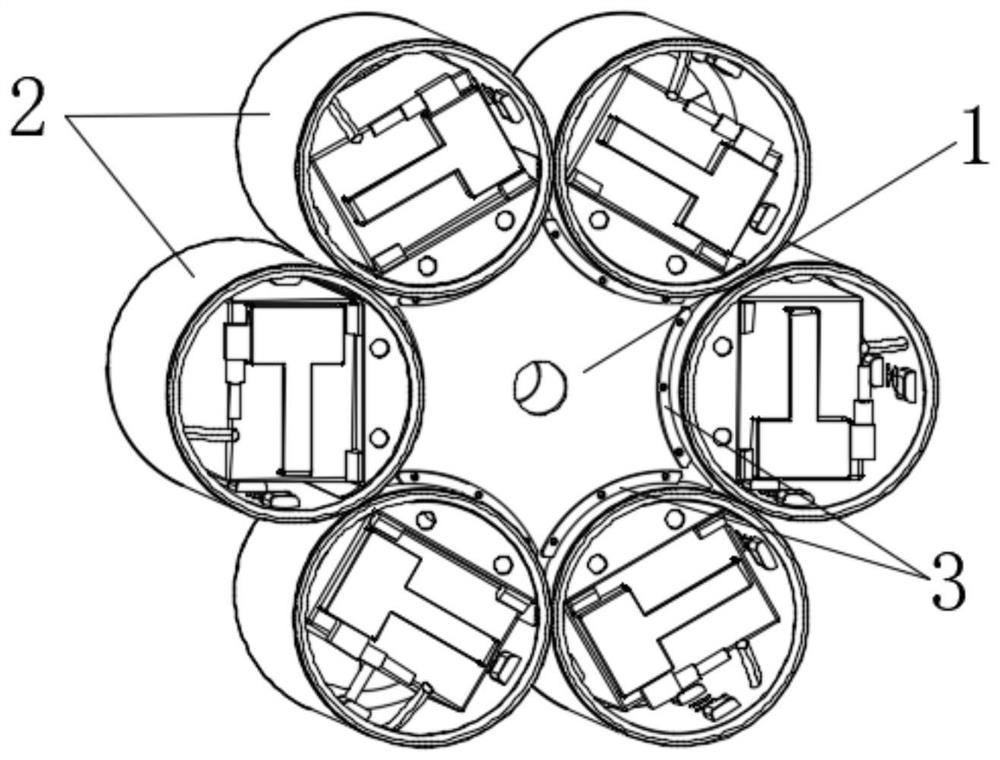

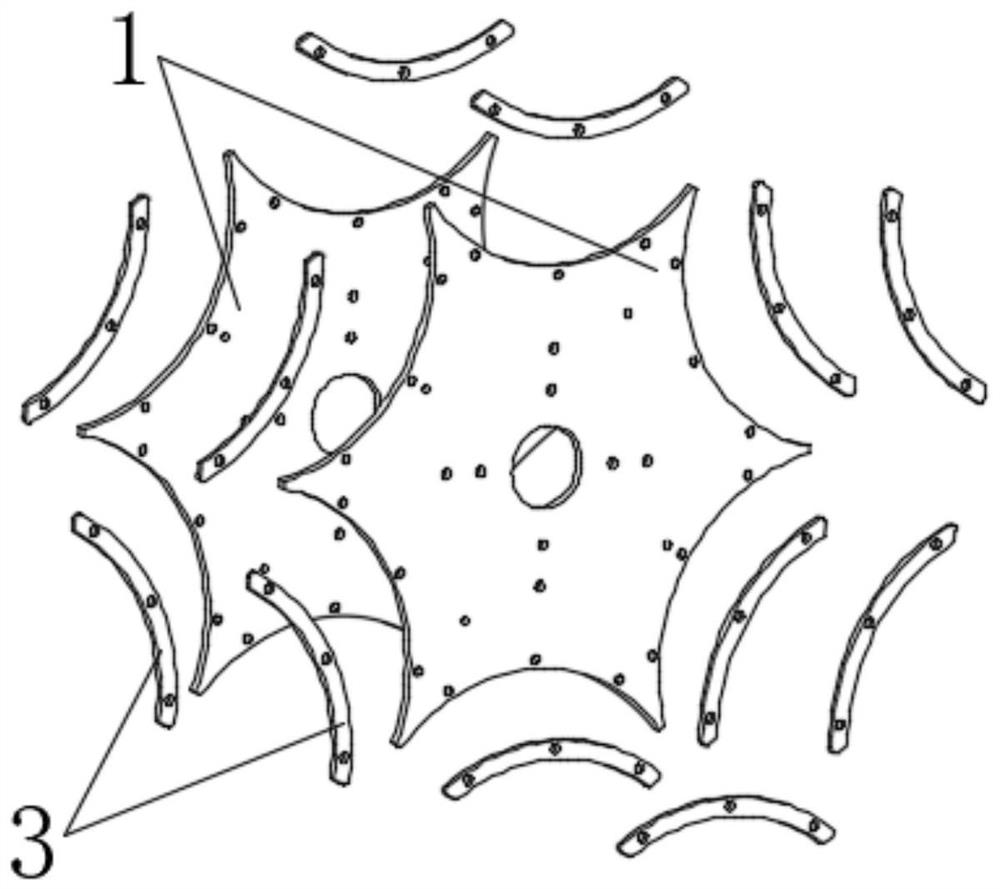

[0035] A battery arrangement structure, such as Figure 1~3 As shown, including the support plate 1 and the battery compartment 2, the side of the support plate 1 is evenly provided with a plurality of concave arcs, the support plate 1 is arranged as a rotationally symmetrical structure, and a plurality of battery compartments 2 are arranged around the side of the support plate 1, each The outer edge of each battery compartment 2 corresponds to each concave arc one by one.

[0036] Among them, the number of battery compartments 2 and concave arcs is 6, and the circle formed by the centers of 6 battery compartments 2 and the circles formed by the vertices of 6 concave arcs are concentric circles, so that the circumferential direction of each battery compartment 2 can be guaranteed. It is stable and safe during rotation, and the outer edge of the battery compartment 2 corresponds to each concave arc one by one, so that the arrangement structure is the densest overall structure, ...

Embodiment 2

[0049] A battery arrangement method such as Figure 6 shown, including the following steps:

[0050] Evenly set a plurality of concave arcs of equal size on the side of the support plate 1, so that each concave arc equally divides the side of the support plate 1;

[0051] A battery compartment 2 is installed on each concave arc, and the outer edge of each battery compartment 2 corresponds to each concave arc;

[0052] A plurality of battery compartments 2 containing batteries are lined up on the side of the support plate 1 , and the outer edges of the plurality of battery compartments 2 touch each other.

[0053] Preferably, each concave arc completely bisects the sides of the support plate 1, so that the structure of the support plate 1 is more uniform.

[0054] Preferably, there are 6 concave arcs and 6 battery compartments 2, and the height of each battery compartment 2 is equal.

[0055] Obviously, through the above-mentioned arrangement, the six battery compartments 2 ...

Embodiment 3

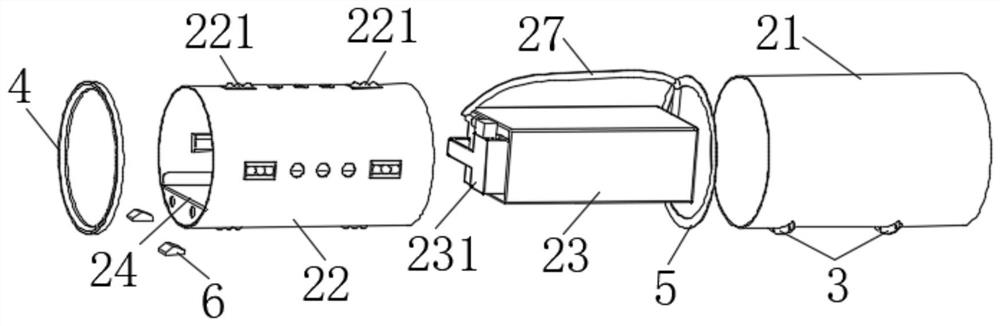

[0057] The difference between this embodiment and Embodiment 1 is that in order to improve the heat dissipation efficiency of the second cabin body 22, the top plate 242 is provided with air holes communicating with the first cavity 26 and the second cavity 27 at the same time, and a plurality of air holes are evenly distributed on the top plate 242, and the plurality of air holes correspond to the plurality of through holes provided on the upper side wall and the lower side wall of the second cabin body 22, wherein both the air holes and the through holes have good ventilation and heat dissipation performance, so that the battery module 23 can be effectively improved. The heat dissipation efficiency during charging inside the second compartment body 22 improves the service life of the battery compartment 2 .

[0058] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com