A kind of yam starch sugar making method

A technology of yam starch and amylase, applied in the direction of fermentation, can solve the problems such as the inability to accurately detect the pH value of starch milk at all times, the inability to exert the maximum effect of amylase, the loss of starch by-products, etc., and achieve easy dissolution and liquefaction, absorption and swelling Strong, fast heating and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

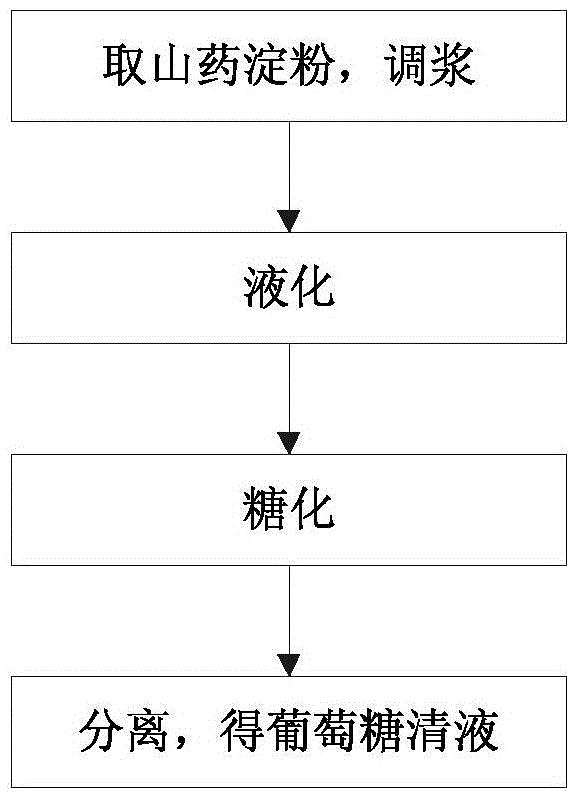

[0021] Such as figure 1 Shown, the present invention provides a kind of yam starch sugar making method, comprises the steps:

[0022] 1) Sizing: take the starch extracted from the yam waste residue and weigh the quality of the yam starch, put the yam starch into the batching tank and add magnetized water to prepare the starch milk until the mass volume concentration is 35%, and adjust the pH with the magnetized aqueous solution of NaOH is 5.6, add CaCl according to the mass fraction ratio of 0.8‰ 2 , Calcium ions are closely combined with α-amylase, a small amount of calcium ions can make α-amylase have maximum activity and stability, add high-temperature-resistant α-amylase at a mass fraction ratio of 0.3‰, and stir evenly.

[0023] 2) Liquefaction: After the inner temperature of the preheated double-deck drum type liquefier reaches 85°C, open the stirring rods at the left and right ends of the double-deck drum type liquefier and keep the rotating speed at 50rpm, and the yam...

Embodiment 2

[0029] 1) Sizing: take the starch extracted from the yam waste residue and weigh the quality of the yam starch, put the yam starch into the batching tank and add magnetized water to prepare the starch milk until the mass volume concentration is 40%, and adjust the pH with the magnetized aqueous solution of NaOH is 5.8, add CaCl according to the mass fraction ratio of 1.2‰ 2 , Calcium ions are closely combined with α-amylase, a small amount of calcium ions can make α-amylase have maximum activity and stability, add high-temperature-resistant α-amylase at a mass fraction ratio of 0.5‰, and stir evenly.

[0030] 2) Liquefaction: after the inner layer temperature of preheating double-deck drum type liquefier reaches 90 DEG C, open the stirring bars at the left and right ends of the double-deck drum type liquefier and keep the rotating speed at 60rpm, and the yam starch milk obtained in step 1) from After the feed port above the double-layer drum-type liquefier is slowly injected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com