A solution sampling mixer

A stirrer and solution technology, applied in the field of solution sampling stirrers, can solve the problems of large storage equipment, uneven content in upper and lower parts, and easily scalded personnel, etc., achieving reliable sampling and analysis results, solving uneven solution, Simple and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

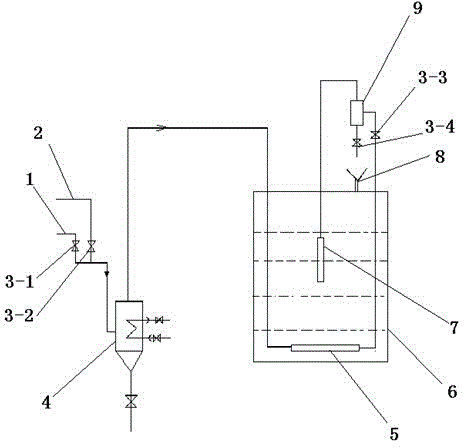

[0020] Such as figure 1 Shown, a kind of solution sampling stirrer comprises solution storage tank 6, and the bottom of described solution storage tank 6 is provided with first gas distributor 5 at 15-25cm from its bottom end face, and the input end of first gas distributor 5 is connected There is a cooler 4, and the input ends of the cooler 4 are respectively connected with the air pipe 1 and the nitrogen pipe 2; the output end of the first gas distributor 5 is connected with the input end of the gas-liquid separator 9; the gas-liquid separation There is a funnel 8 directly below the liquid outlet pipe at the bottom of the device 9; the top gas outlet of the gas-liquid separator 9 is connected to the input end of the second gas distributor 7 located in the middle of the solution storage tank 6 .

[0021] Further, the air pipe 1 and the nitrogen pipe 2 are respectively provided with a first air intake valve 3-1 and a second air intake valve 3-2. A liquid outlet valve 3-4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com