Rail type movable triaxial apparatus

A triaxial instrument and orbital technology, applied in the field of orbital dynamic triaxial instrument, can solve the problems of occupancy, increase equipment cost, multi-laboratory space, etc., achieve the effect of reducing discrete, improving test efficiency and realizing continuous test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

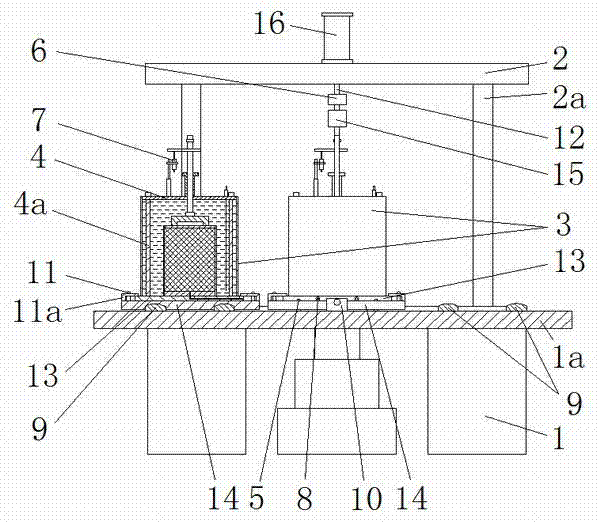

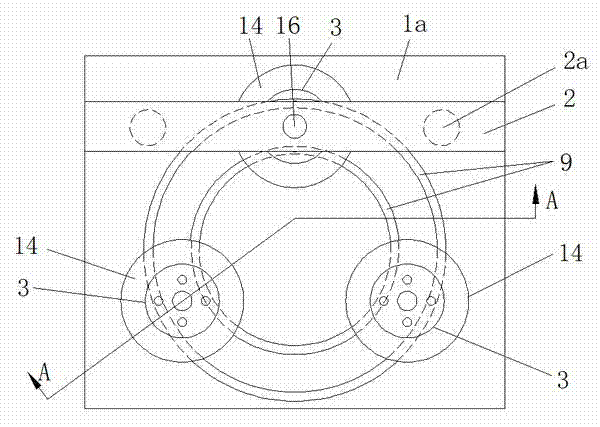

[0013] The present invention will be described below with reference to the accompanying drawings.

[0014] figure 1 , 2 A structural diagram of an orbital moving triaxial instrument is shown. In the figure, an orbital moving triaxial instrument includes a body 1 provided with a working platform 1a and a frame beam 2 supported by a column 2a, and two circular rails 9 are provided on the working platform 1a. The base of the pressure chamber 3 It includes an upper base 13 and a lower base 14, wherein the lower base 14 is provided with two arc-shaped grooves, which are connected with the two circular rails 9 by ball inlay.

[0015] A piston rod 12 that applies a reciprocating load and a pressure sensor 6 connected to the piston rod 12 are fixed on the frame beam 2. The force transmission shaft 12a connected to the pressure chamber cover 4 is connected to the piston rod 12 through the sleeve 15, and the piston rod 12 is connected. A displacement sensor 7 is fixed on the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com