Single hall proximity sensor ship stern shaft speed measuring device

A technology of proximity sensor and speed measuring device, which is applied to measuring devices, devices using electric/magnetic methods, instruments, etc., to achieve the effects of ensuring speed measuring accuracy, simple installation, and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

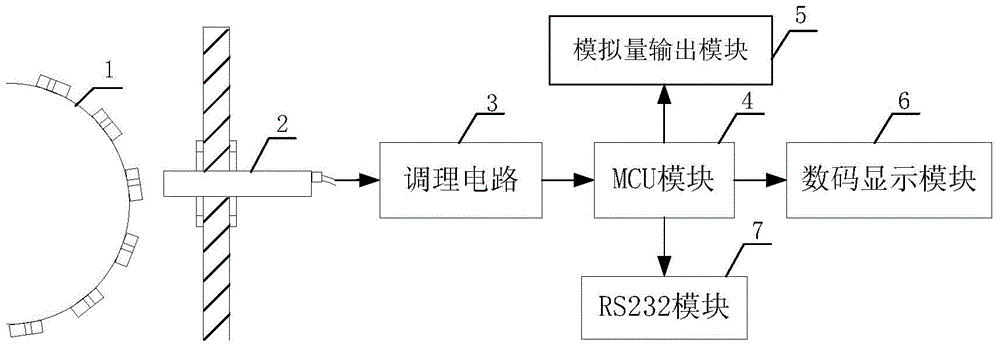

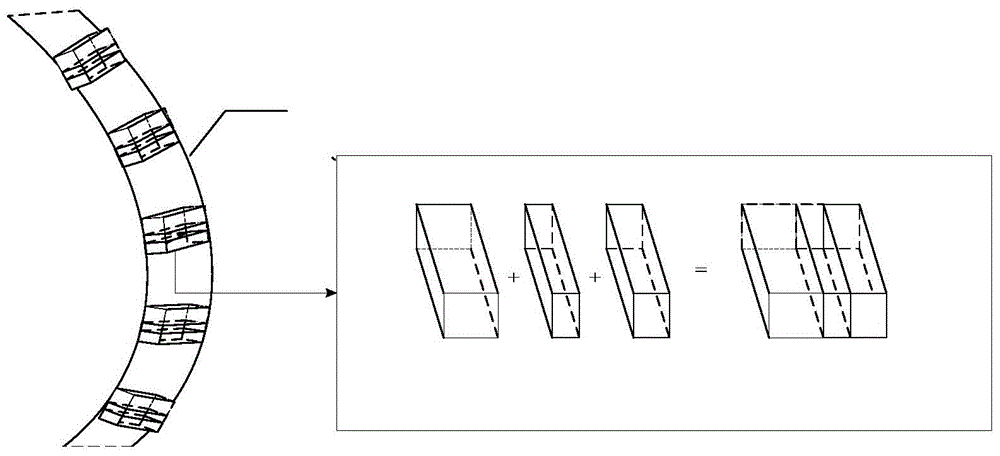

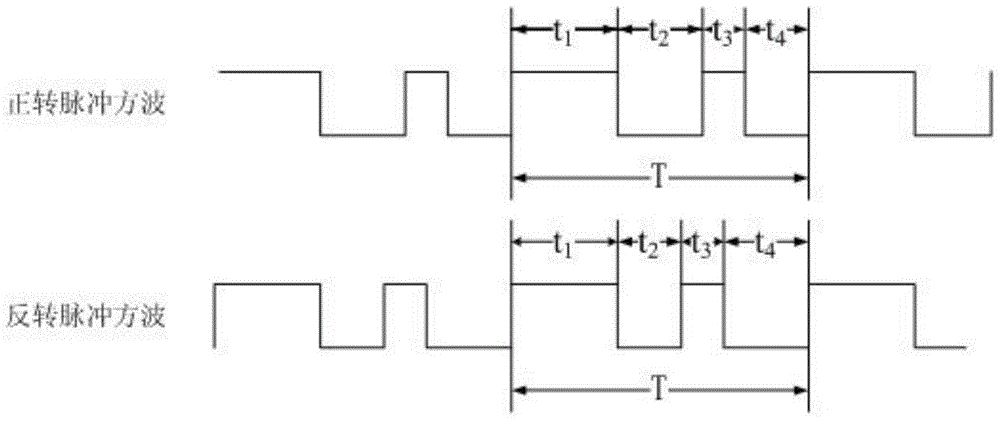

[0018] The ship stern shaft velocity measuring device of single Hall proximity sensor provided by the present invention, its structural principle is as follows figure 1 As shown, it includes a permanent magnet hoop 1, a Hall proximity sensor 2, an input conditioning circuit 3 connected by electrical signals, a single-chip microcomputer 4, an analog output module 5, a digital display module 6, and an RS232 communication module 7. Among them: the permanent magnet hoop 1 is installed on the stern shaft of the ship, and the Hall proximity sensor 2 is aligned with the magnetic steel of the permanent magnet hoop. When the magnet on the permanent magnet hoop 1 rotates with the stern shaft, the Hall proximity sensor 2 The pulse square wave is induced, and the pulse square wave signal is conditioned by the conditioning circuit 3 and then input to the single-chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com