Making method of combined clothes

A production method and combined technology, applied in the direction of sewing tools and other directions, can solve the problems of wear and tear, local color changes, low efficiency of garment making, etc., and achieve the effects of avoiding dependence, reducing costs, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

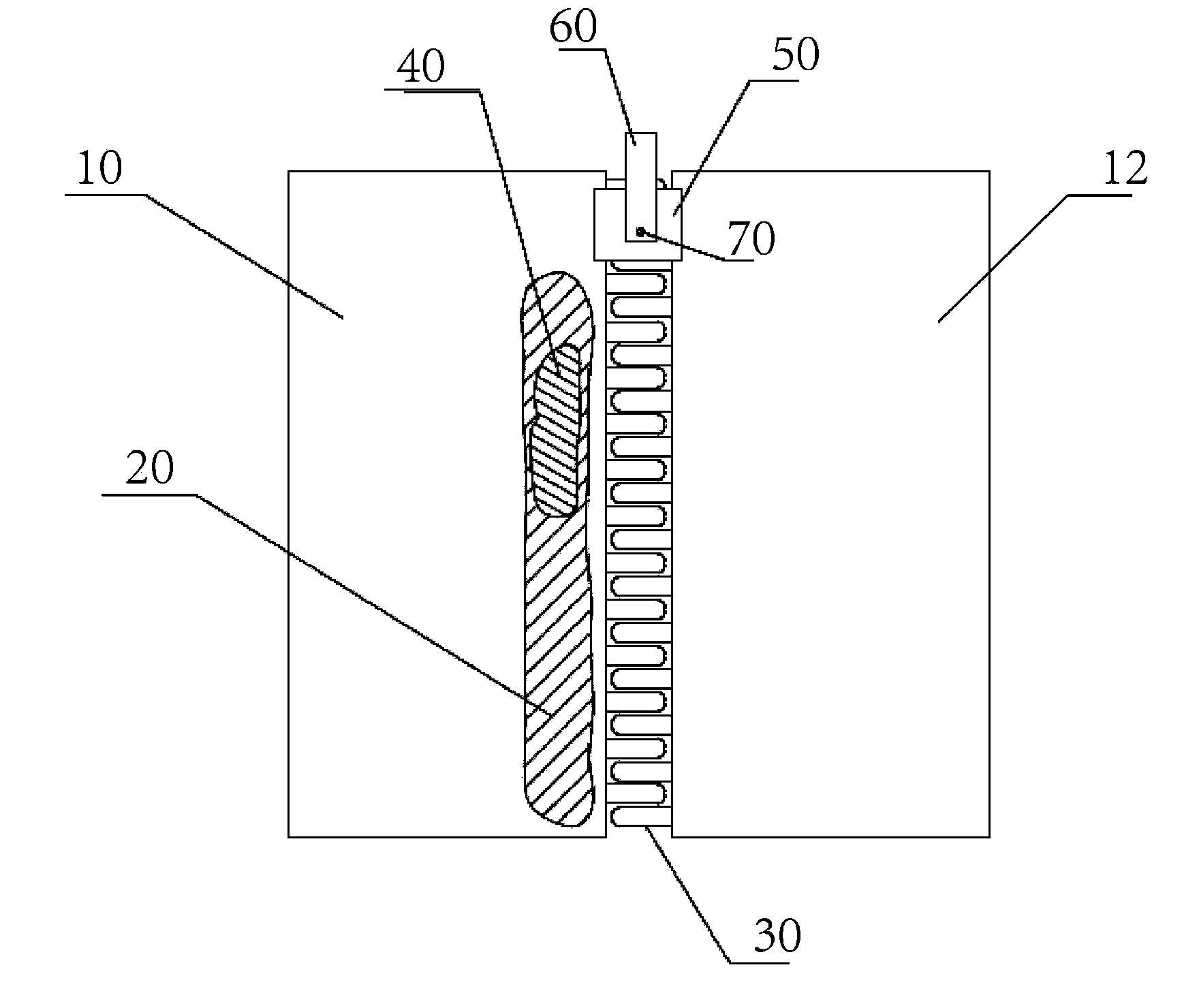

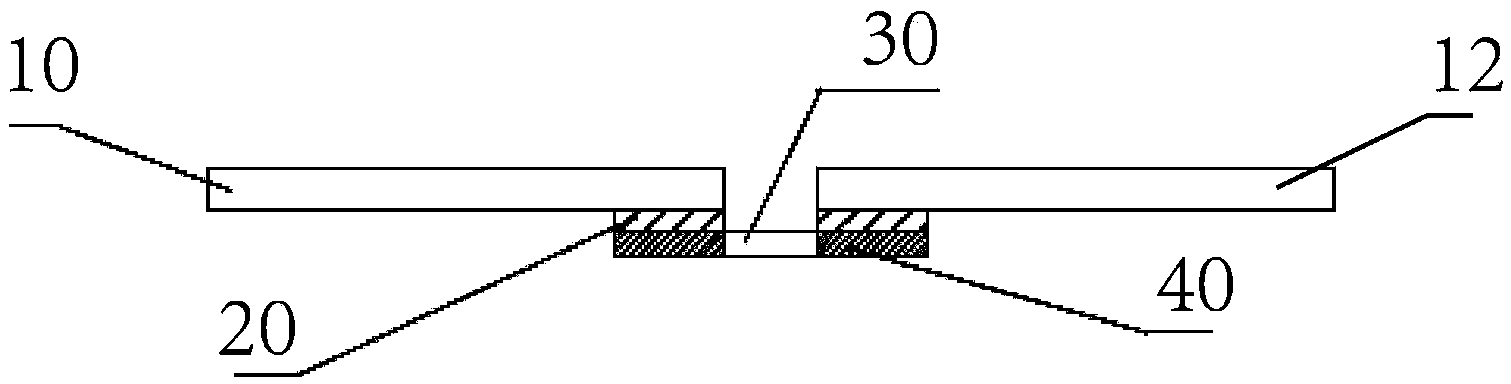

[0022] The present invention will be further described below in conjunction with embodiments and accompanying drawings.

[0023] A kind of manufacture method of combined clothes, see figure 1 with figure 2 , comprising the following steps: the clothing pieces to be combined have splicing positions on both sides,

[0024] Adhesive tape is arranged between one side splicing part of the clothing pieces to be combined and the first side zipper tape 40 of the zipper, and fixed, the fixing method is an adhesive form, and the two are bonded by heat and pressure treatment, so The temperature of the hot pressing treatment is 120°C, the time is 15s, and the pressure applied to the cloth surface is 5bar. Adhesive tape 20 is arranged between, fixes, thus completes that the splicing position on both sides of this garment panel to be assembled is respectively connected with two zipper cloth tapes 20, and this garment panel to be assembled promptly forms the first panel 10;

[0025] Adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com