Acidified fracturing fluid continuous mixing and preparation device

A technology of acid fracturing and mixing, which is applied in mixers, mixing methods, transportation and packaging, etc. It can solve the problems of uneven dispersion of chemical additives, low viscosity of base fluid, and poor quality of liquid preparation, and achieve compact structure and acid The effect of high liquid quality and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

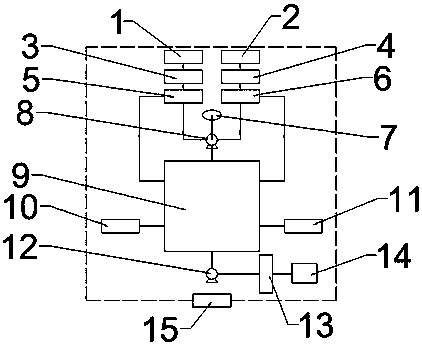

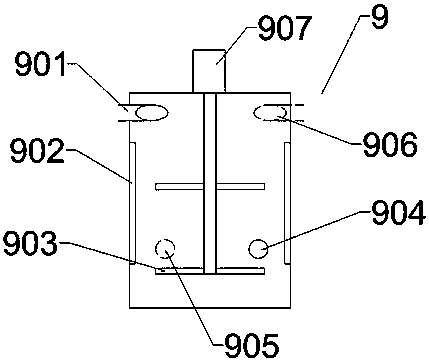

[0020] Under the coordinated control of the PLC system, the present invention integrates the dry powder automatic unpacking device, the dry powder automatic feeding device and the dry powder metering device into a potassium chloride metering and feeding unit 1 and a guar gum metering and feeding unit 2 to realize chlorine Automatic feeding and accurate metering of potassium chloride and guar gum dry powder, and in potassium chloride water powder mixing tank 5, guar gum water powder mixing tank 6, respectively fully mix the powder material measured and the clear water that is pumped in, and Enter the inner wall of the mixing tank 9 through the potassium chloride feed port 901 and the guar gum feed port 906 along the tangential line, and then according to the liquid ratio required for the liquid preparation, the acid liquid and various chemical additives are respectively passed through respective self-priming pumps, The flow sensor, the regulating valve, and the tangential pump a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com