A new type of exhaust heating device for photovoltaic glass production

A photovoltaic glass and heating device technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of inability to achieve rapid melting of gate plate solidified glass, inability to adjust horizontal spacing simultaneously, and uneven flame intensity, etc. problems, to shorten the time for replacing lip bricks and calenders, achieve good results, and improve the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

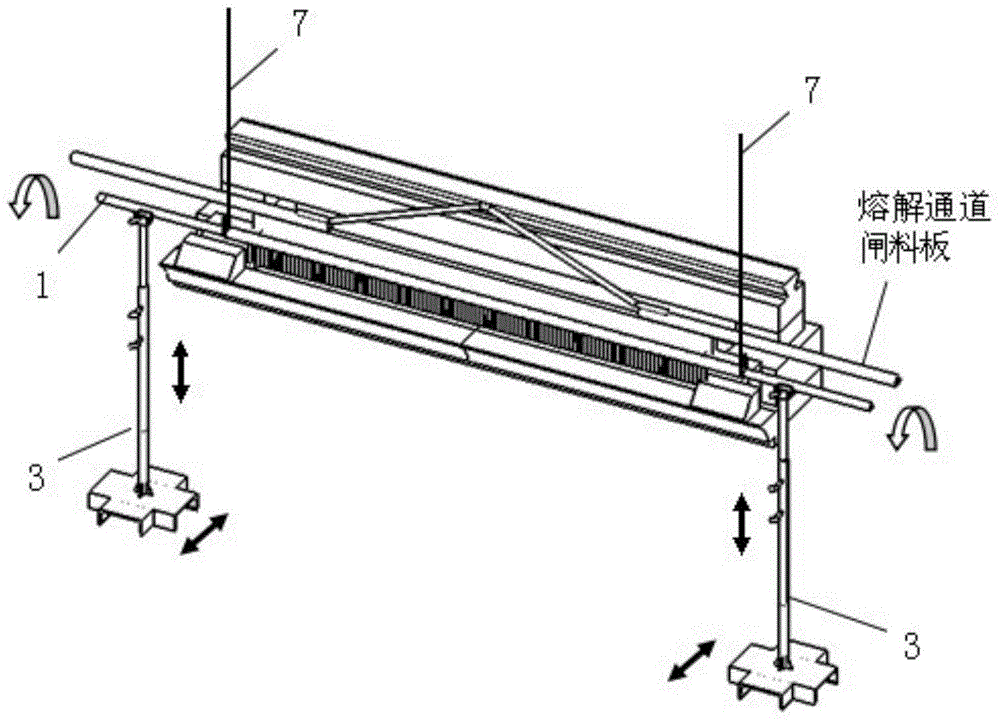

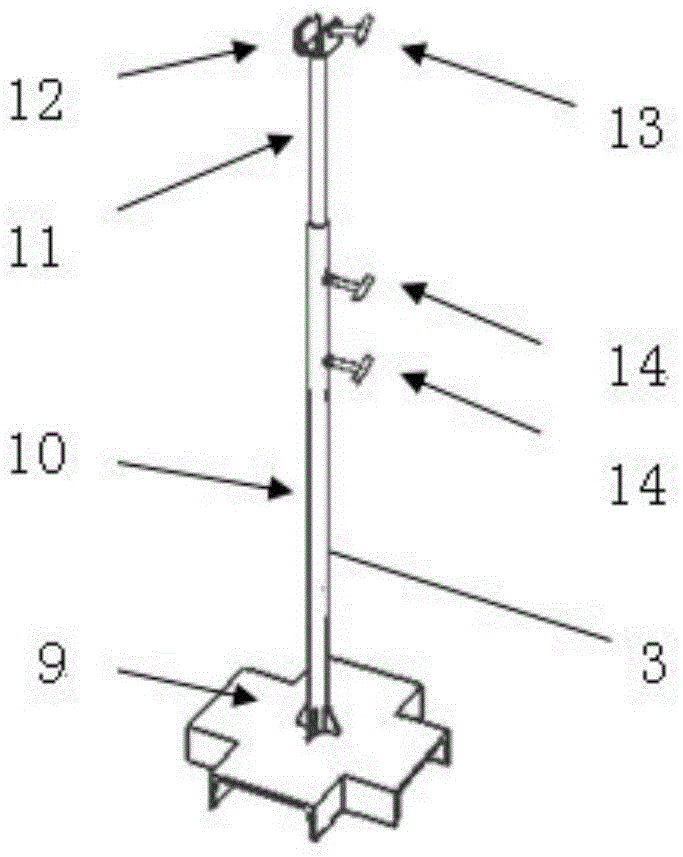

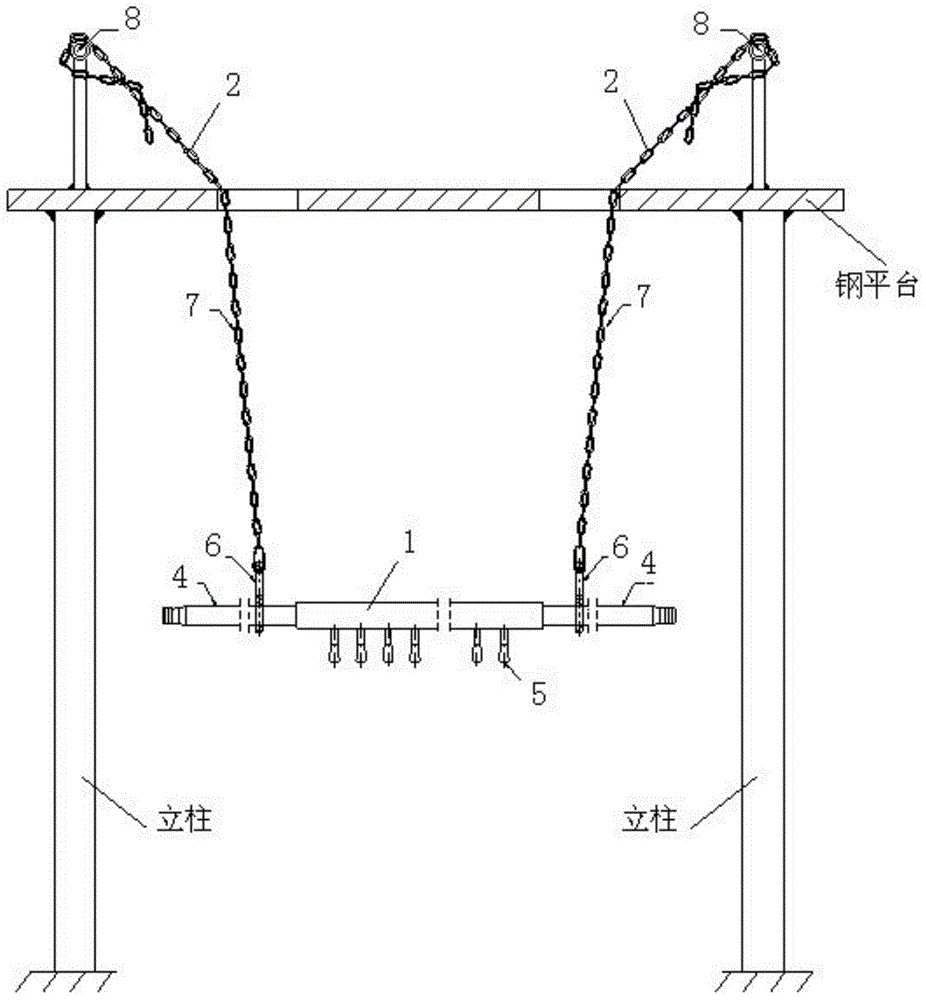

[0015] See attached figure 1 , 2 , 3, a new type of photovoltaic glass production exhaust heating device, including exhaust heat gun 1, suspension device 2 and support 3; exhaust heat gun 1 includes connecting rod 4, and connecting rod 4 is evenly arranged with nozzles in a straight line 5. The connecting rod 4 is connected with the suspension chain 7 of the suspension device 2 through the chain connector 6; the suspension device 2 includes a suspension chain 7 and a special beam 8; the bracket 3 includes a movable base 9, and the movable base 9. The center is fixedly welded with a fixed rod 10. The top of the fixed rod 10 is provided with a movable rod 11. The movable rod 11 can be telescopically moved in the fixed rod 10 to adjust the height of the exhaust heat gun 1 up and down. 14 is locked and fixed, and the top of the movable rod 11 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com