A glass tube twisting device

A glass tube and twisting technology, which is applied in the field of glass tube twisting devices, can solve the problems of inconvenient production and processing of glass tubes, and there is no device for processing twisted structures, etc., and achieves simple structure, high processing efficiency, and improved processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

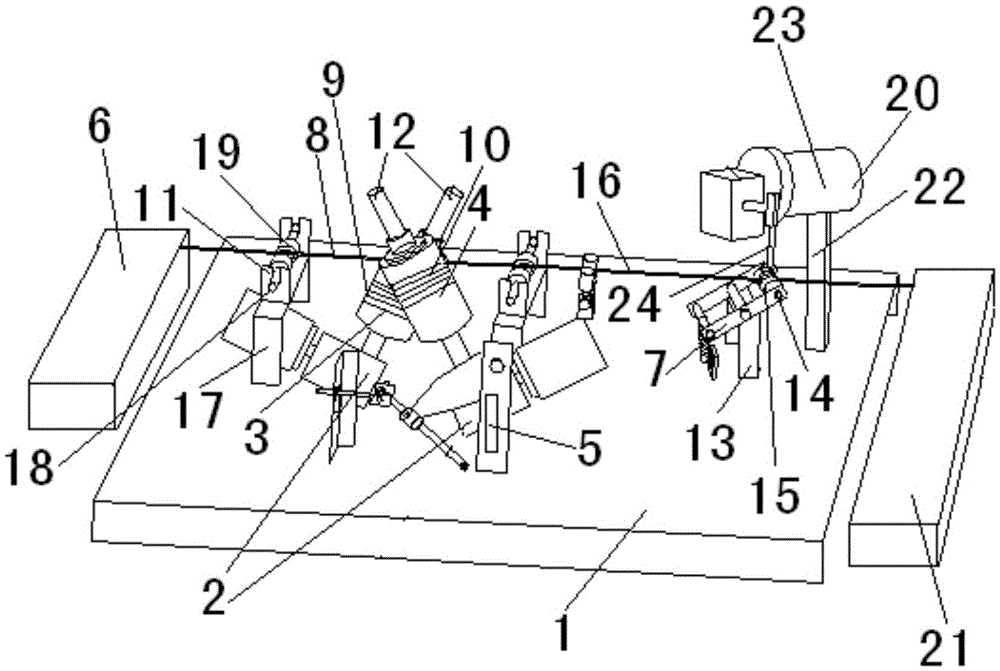

[0016] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0017] as attached figure 1 As shown, the present invention is a glass tube twisting device, including a device base 1, two drive parts 2 are arranged on the device base 1, and pressure roller I3 and pressure roller II4 are respectively arranged on the two drive parts 2. Roller Ⅰ3 and pressure roller Ⅱ4 are arranged in an X shape. The roller surfaces of pressure roller Ⅰ3 and pressure roller Ⅱ4 are close to each other. The controller 5 that starts and stops the component 2 is connected.

[0018] Preferably, the front end of the device base 1 is provided with a glass tube original processing part 6, and the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com