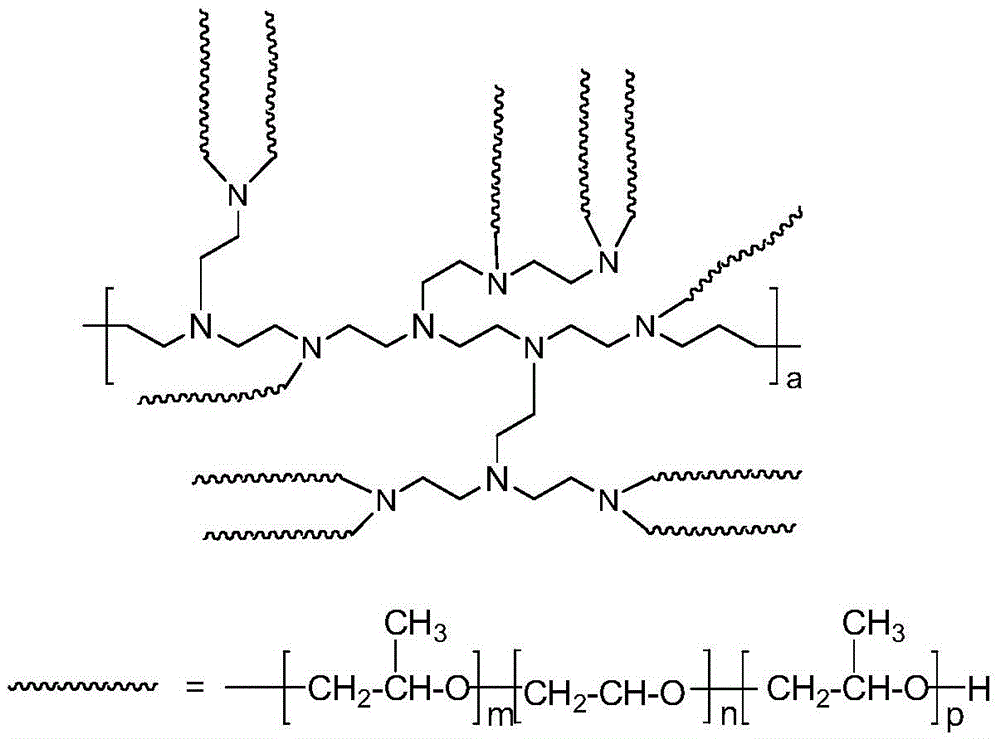

A block polyether demulsifier using polyethyleneimine as an initiator and its preparation method

A technology of polyethyleneimine and block polyether, which is applied in the direction of dehydration/demulsification by chemical methods, and can solve the problems of deteriorating water quality and dehydration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

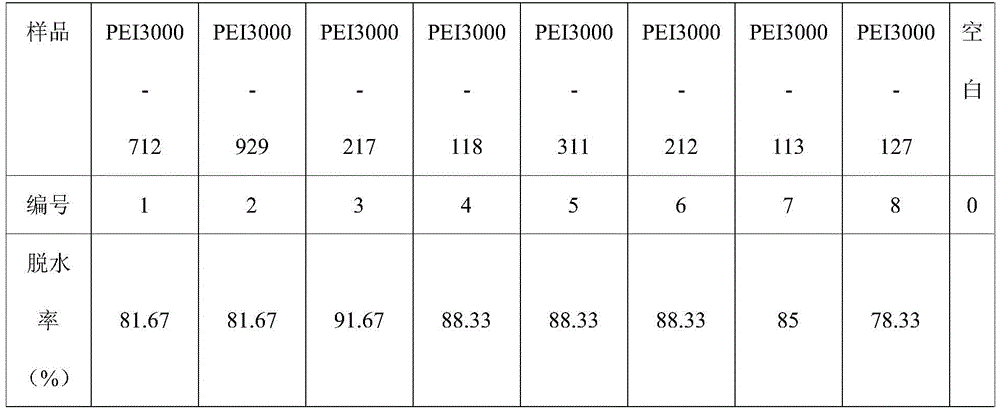

Examples

Embodiment 1

[0022] Example 1 Preparation of Ethylene Oxide and Propylene Oxide Block Polyether Demulsifier Using Polyethyleneimine (Mw=600) as Initiator

[0023] Add 10g of polyethyleneimine and 24g of potassium hydroxide into the high-temperature and high-pressure reactor, and seal the reactor well. Before heating up, use nitrogen to blow and replace, then use a vacuum pump to evacuate, repeat twice, then start stirring and raise the temperature, stop heating when the temperature rises to 120°C, open the feed valve, add 800g of propylene oxide dropwise, and control the reaction The temperature does not exceed 140°C and the pressure is controlled below 0.4MPa. After the reaction of the material is completed, the pressure drops and then reacts for 30 minutes to reduce the pressure to 0MPa; then, heat to 120°C and then add 800g of ethylene oxide, and control the reaction temperature not to exceed 150°C and the pressure is controlled below 0.4MPa. After the reaction of the material is comple...

Embodiment 2

[0025] Adopt the method with embodiment 1, but change the quality of the propylene oxide that adds for the first time, ethylene oxide and the propylene oxide that add for the second time are respectively 800g, 400g and 2800g, obtain the polyethyleneimine (Mw =600) as the initiator of ethylene oxide and propylene oxide block polyether demulsifier, marked as PEI600-217.

Embodiment 3

[0027] Adopt the method with embodiment 1, but change the quality of the propylene oxide that adds for the first time, ethylene oxide and the propylene oxide that adds for the second time to be 800g, 4800g and 7200g respectively, obtain polyethyleneimine (Mw =600) as the initiator of ethylene oxide and propylene oxide block polyether demulsifier, marked as PEI600-169.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com