Intermittent device for part production of general gasoline engine

A part and machine technology, which is applied in the field of intermittent devices for the production of machine parts, can solve the problems of unstable intermittent frequency of manual operation, poor processing cooling effect, etc., and achieves good processing cooling effect, simple structure, and anti-reverse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

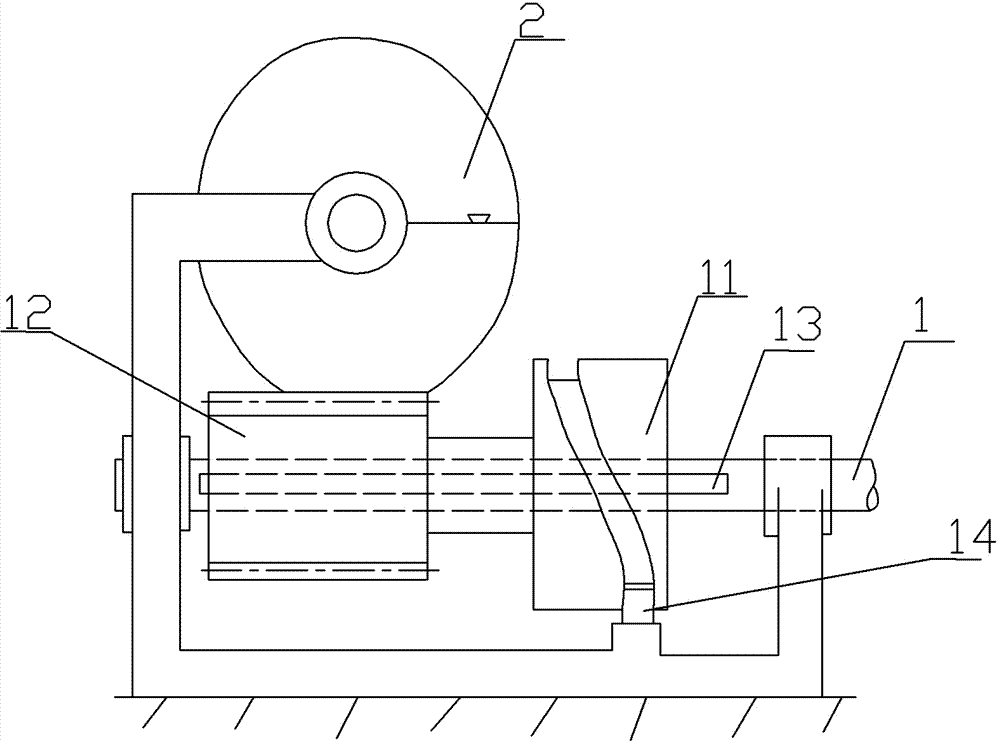

[0010] according to figure 1 As shown, the intermittent device for the production of general machine parts in the embodiment of the present invention includes a frame, and also includes an input shaft 1 that is rotatably connected with the frame and is provided with a chute 13, an output shaft that is rotatably connected with the frame, and is fixed on The worm wheel 2 on the output shaft and the worm part that slides along the chute 13; the worm part includes a worm 12 meshed with the worm wheel 2 and a grooved cam 11 fixed integrally with the worm 12, and the frame is also provided with a grooved cam 11 The fixed block 14 matched with the annular groove on the top, the worm wheel 2 includes a left half and a right half, and the end faces of the left half and the right half are provided with inverted tapered protrusions and inverted tapere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com