Blast furnace slag flushing water heat exchanger on-line cleaning device

A blast furnace slag flushing water and heat exchanger technology, which is applied in the directions of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. , Increase self-cleaning function, enhance service life and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

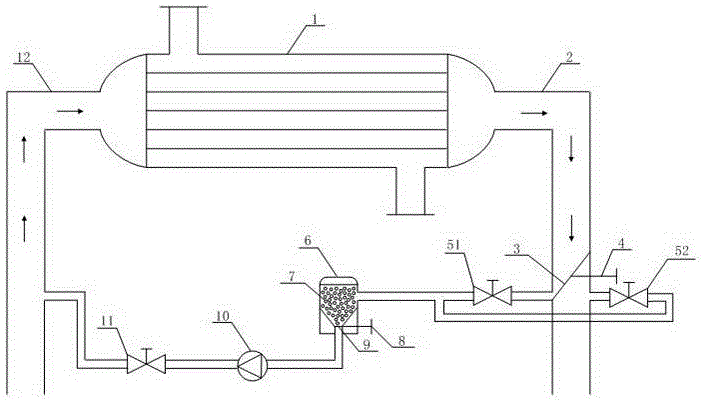

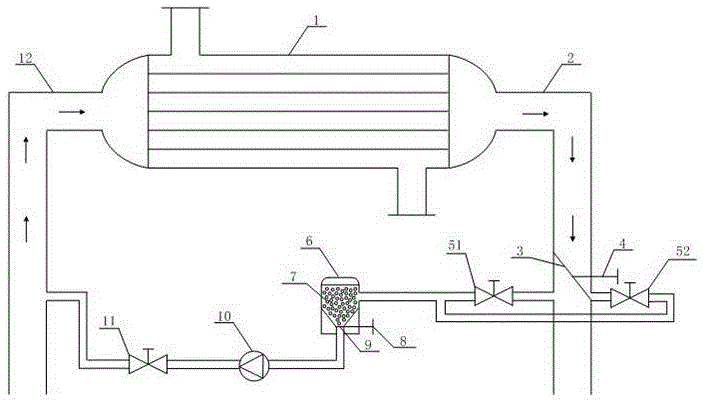

[0011] Such as figure 1 As shown, the blast furnace slag flushing water heat exchanger on-line cleaning device is composed of a ball storage tank 6, a rubber ball pump 10 and supporting pipelines and valves. There is a baffle 9 in the ball storage tank 6, and the baffle 9 is controlled by the baffle handle 8 to control the sending and receiving of the small ball 7; the slag flushing water inlet pipe 12 of the heat exchanger is connected to the ball valve 11 through a branch pipe, The other end of the serving valve 11 is sequentially connected to the rubber ball pump 10 and the ball storage tank 6, and the pipeline at the other end of the ball storage tank 6 is branched, respectively connected to the forward ball collection valve 51 and the reverse ball collection valve 52, and the forward ball collection valve 51 and the reverse ball collecting valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com