Multifunctional printing processing system

A processing system and multi-functional technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of affecting quality, unstable effect, low operation efficiency of thick paper, etc., to reduce costs and error rates, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

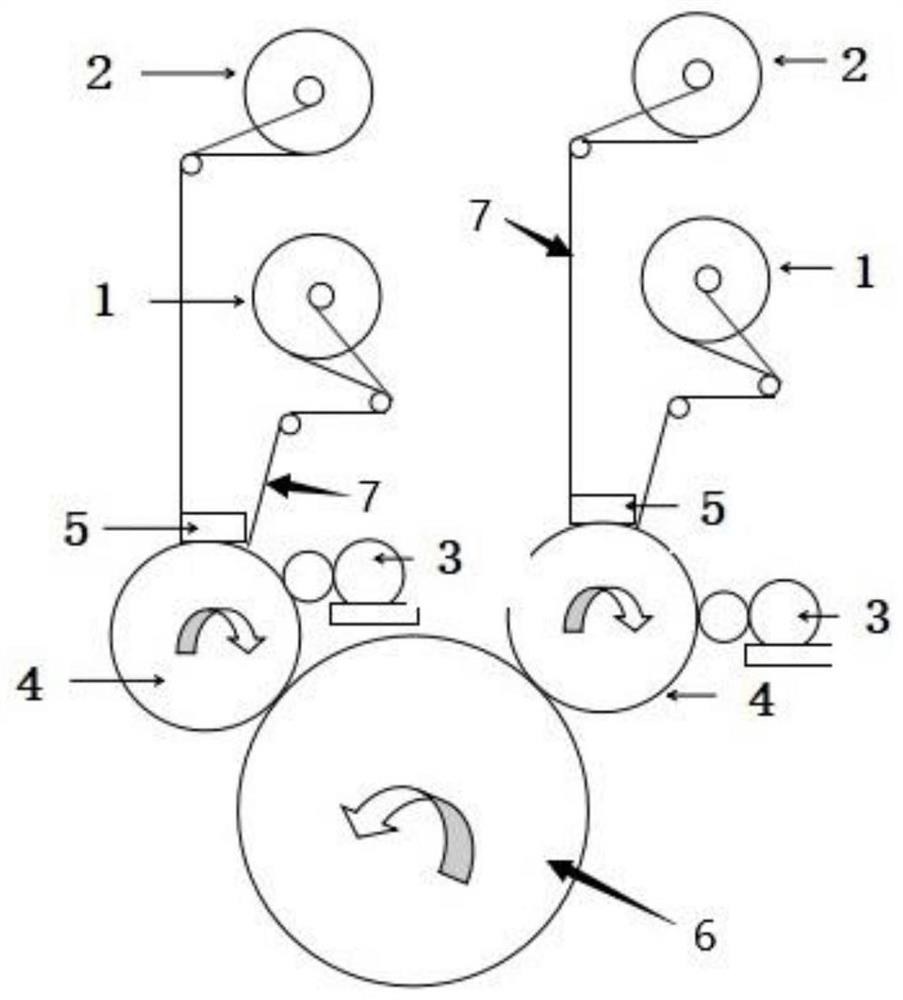

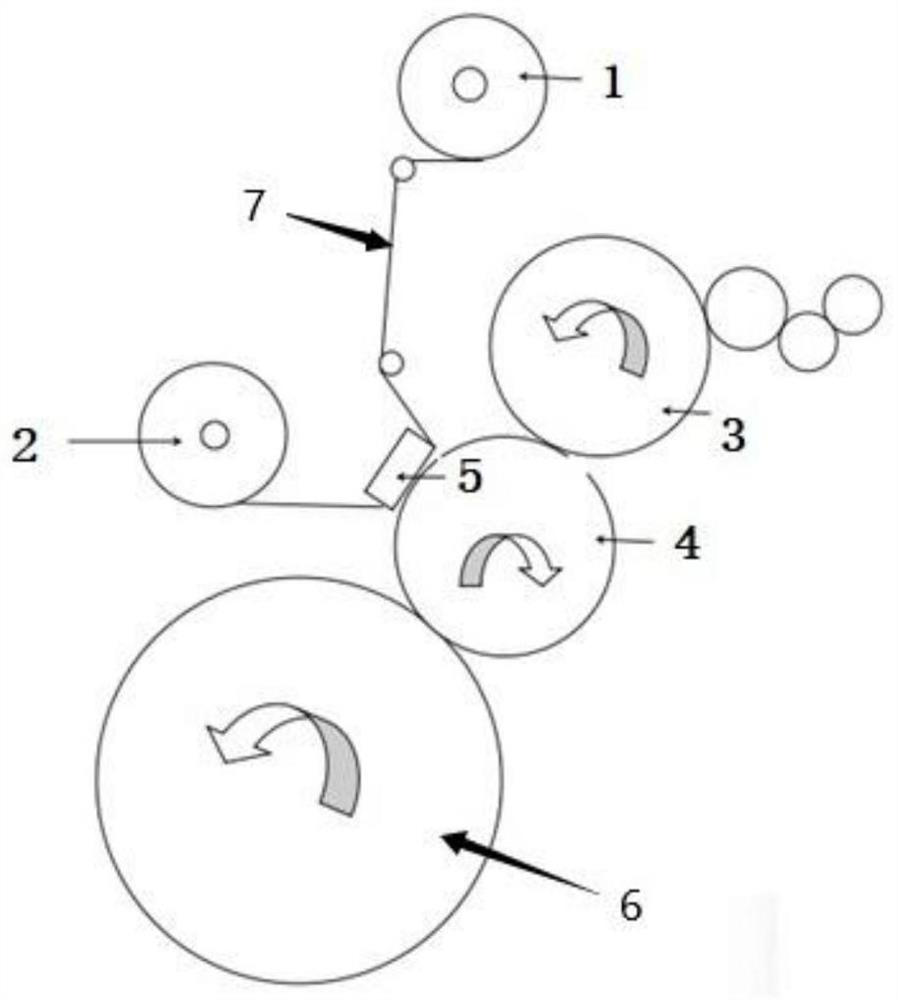

[0035] The printed paper enters the depowdering unit through the jaws of the feeder, and the roller coating device 3 in the depowdering unit transfers water to the rubber roller 4, and the rubber roller 4 with water is pressed together to remove the surface of the printed sheet. Paper dust is stained on the rubber surface of the rubber roller 4 surface; at the same time, the pressed porous device 5 sprays water to the non-woven fabric 7 released from the unwinding shaft 1, and the non-woven fabric 7 is bonded to the rubber roller 4, thereby erasing the rubber roller 4 surface. Paper powder, after the set number of printed sheets is reached, the porous device 5 is released, and the winding shaft 2 rewinds the polluted non-woven fabric; after that, the paper passes through the roller coating device 3 of the second set of powder removal unit to transfer the water to the rubber roller 4 On the surface, the paper powder on the surface of the printed sheet is stained on the surface o...

Embodiment 2

[0037] The printed paper enters the powder removal unit through the jaws of the feeder. The roller coating device 3 of the powder removal unit transfers water to the rubber roller 4, and the rubber roller 4 with water is pressed together to remove the paper on the surface of the printed sheet. Powder, onto the surface of the eraser. At the same time, the pressed porous device 5 sprays water on the non-woven fabric 7 discharged from the unwinding shaft 1, and the non-woven fabric 7 is attached to the rubber roller 4, thereby erasing the paper powder on the surface of the rubber roller 4. After the set number of printed sheets is reached, the porous device 5 from the pressure, the winding shaft 2 will take up the polluted non-woven fabric. After powder removal, the paper enters the coating unit and is partially coated by the flexo printing structure. The coated paper then enters the casting curing unit and is bonded with the holographic casting film. After UV curing, the paper a...

Embodiment 3

[0039] The second set of powder removal unit can be used as a coating unit to save costs and improve efficiency, as follows:

[0040] The printed paper enters the first set of depowdering unit through the teeth gripper after the feeder enters, and the roller coating device 3 of the depowdering unit transfers water to the surface of the rubber roller 4, and the rubber roller 4 with water is pressed together The paper dust on the surface of the printed sheet sticks to the surface of the rubber. At the same time, the pressed porous device 5 sprays water on the non-woven fabric 7 released from the unwinding shaft 1, and the non-woven fabric 7 is attached to the rubber roller 4, thereby erasing the paper powder on the surface of the rubber roller 4. After the set number of printed sheets is reached, the porous device 5 from the pressure, the winding shaft 2 will take up the polluted non-woven fabric. After passing through the first set of powder removal unit, the paper enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com