An engine docking rotation mechanism with detection function

A rotating mechanism and engine technology, which is applied in the direction of engine testing, power measurement, and measuring devices, can solve problems such as low transmission efficiency, inaccurate test data, and low docking efficiency, and achieve high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

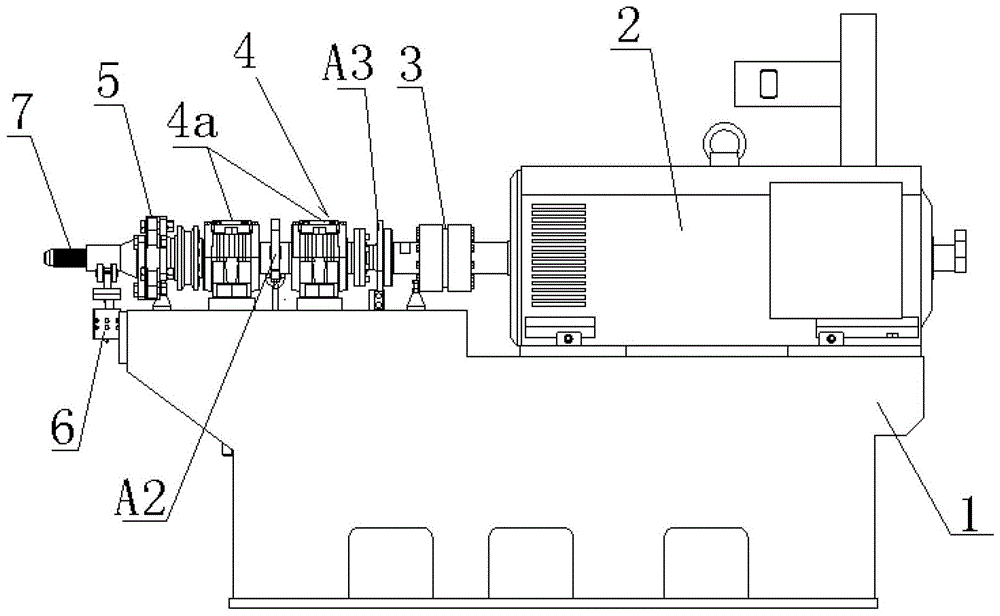

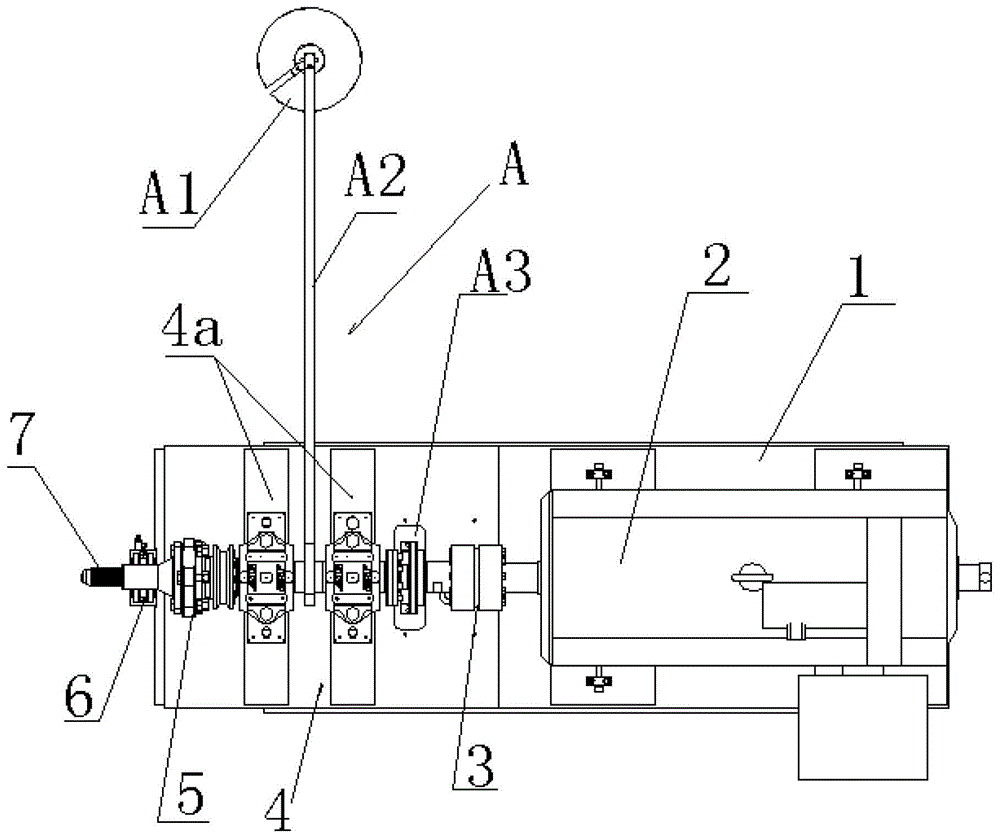

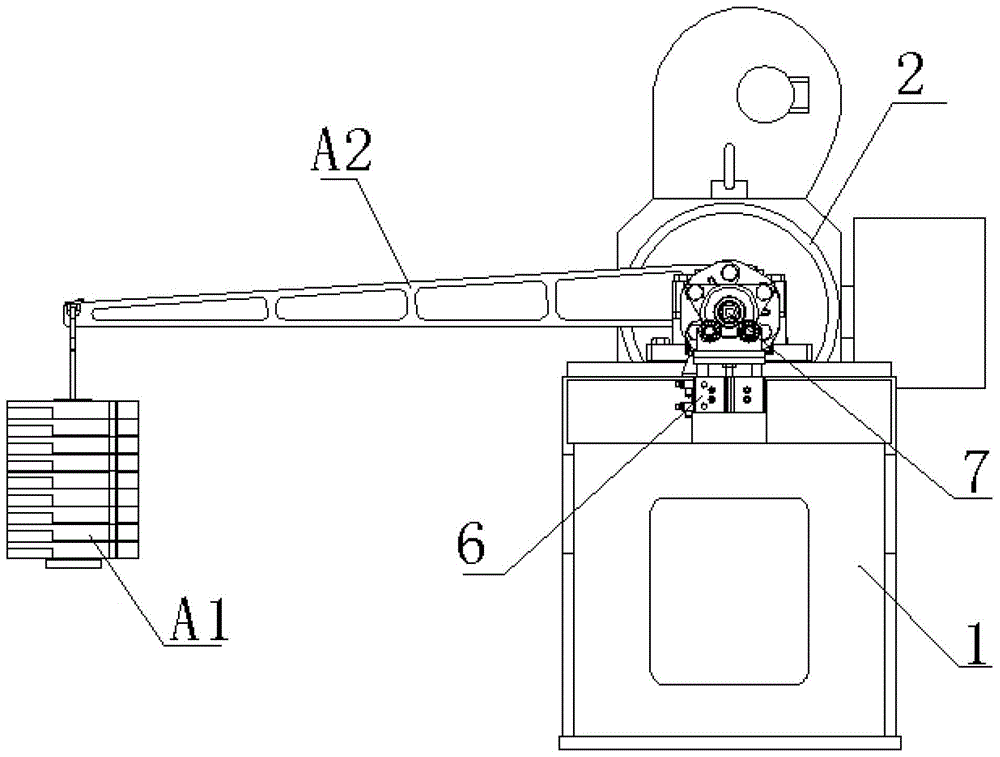

[0024] Such as Figure 1 to Figure 4 As shown, an engine docking rotation mechanism with a detection function includes a driving motor 2 arranged on a test platform 1, and the driving motor is connected to one end of a bearing seat group 4 arranged on the test platform through a coupling 3. The bearing seat The other end of the group is axially connected with the spline 7 provided with the positioning cylinder 6 at the lower part through the elastic coupling 5, and a torque detection device A is provided at the bearing seat group.

[0025] The bearing housing group 4 is specifically two bearing housings 4a arranged side by side and coaxially connected.

[0026] The torque detection device A includes an adjustment weight A1, a weight suspension rod A2 and a torque sensor A3, specifically, one end of the weight suspension rod is sleeved on the shaft body between the two bearing seats 4a, and the weight suspension rod An adjustment weight is suspended at the other end, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com