A cooling method for internal cooling and external cooling of rotor magnetic poles

A technology of rotor magnetic pole and cold partition, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of unsatisfactory cooling effect, etc., to improve cooling effect, reduce ventilation resistance, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

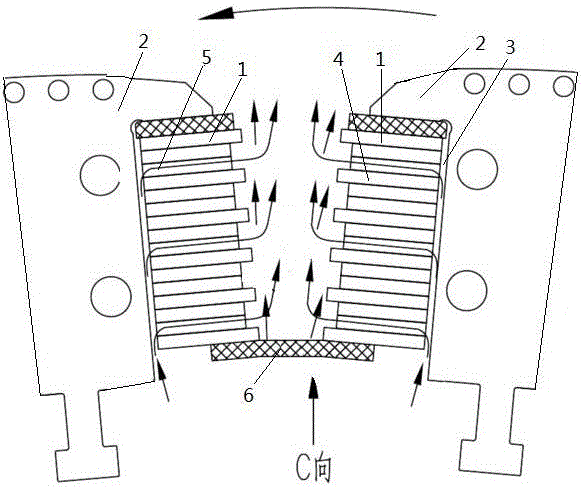

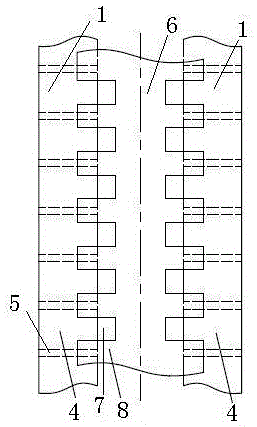

[0031] A method for sub-regional cooling between internal cooling and external cooling of rotor magnetic poles. The cooling gas flows into the channel between the two magnetic pole coils 1 through the ventilation partition device 6 on the air inlet end of the two magnetic pole coils 1 to form an external cooling ventilation air path, and The outside of the pole coil 1 is cooled, and at the same time the cooling gas flows into the inside of the pole coil 1 through the gap between the pole core 2 and the pole coil 1, forming an internal cooling ventilation air path, and cooling the inside of the pole coil 1, and then from the pole coil 1 internally flows into the channel between the two magnetic pole coils 1, and the ventilation partition device 6 separates the external cooling ventilation air path and the internal cooling ventilation air path flowing into the channel from each other.

[0032] This embodiment is the most basic implementation mode. Using this method, the cooling g...

Embodiment 2

[0034] A method for sub-regional cooling between internal cooling and external cooling of rotor magnetic poles. The cooling gas flows into the channel between the two magnetic pole coils 1 through the ventilation partition device 6 on the air inlet end of the two magnetic pole coils 1 to form an external cooling ventilation air path, and The outside of the pole coil 1 is cooled, and at the same time the cooling gas flows into the inside of the pole coil 1 through the gap between the pole core 2 and the pole coil 1, forming an internal cooling ventilation air path, and cooling the inside of the pole coil 1, and then from the pole coil 1 internally flows into the channel between the two magnetic pole coils 1, and the ventilation partition device 6 separates the external cooling ventilation air path and the internal cooling ventilation air path flowing into the channel from each other.

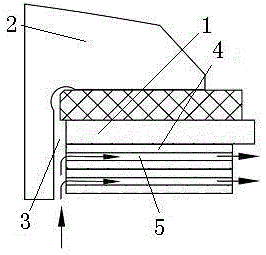

[0035]The magnetic pole coil 1 is formed by stacking multi-layer current-carrying bars 4, and ...

Embodiment 3

[0038] A method for sub-regional cooling between internal cooling and external cooling of rotor magnetic poles. The cooling gas flows into the channel between the two magnetic pole coils 1 through the ventilation partition device 6 on the air inlet end of the two magnetic pole coils 1 to form an external cooling ventilation air path, and The outside of the pole coil 1 is cooled, and at the same time the cooling gas flows into the inside of the pole coil 1 through the gap between the pole core 2 and the pole coil 1, forming an internal cooling ventilation air path, and cooling the inside of the pole coil 1, and then from the pole coil 1 internally flows into the channel between the two magnetic pole coils 1, and the ventilation partition device 6 separates the external cooling ventilation air path and the internal cooling ventilation air path flowing into the channel from each other.

[0039] The magnetic pole coil 1 is formed by stacking multi-layer current-carrying bars 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com