Part distribution device of automatic assembling device

A technology of automatic assembly and shunt device, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low shunt efficiency and complex structure, and achieve the effect of high shunt efficiency and simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

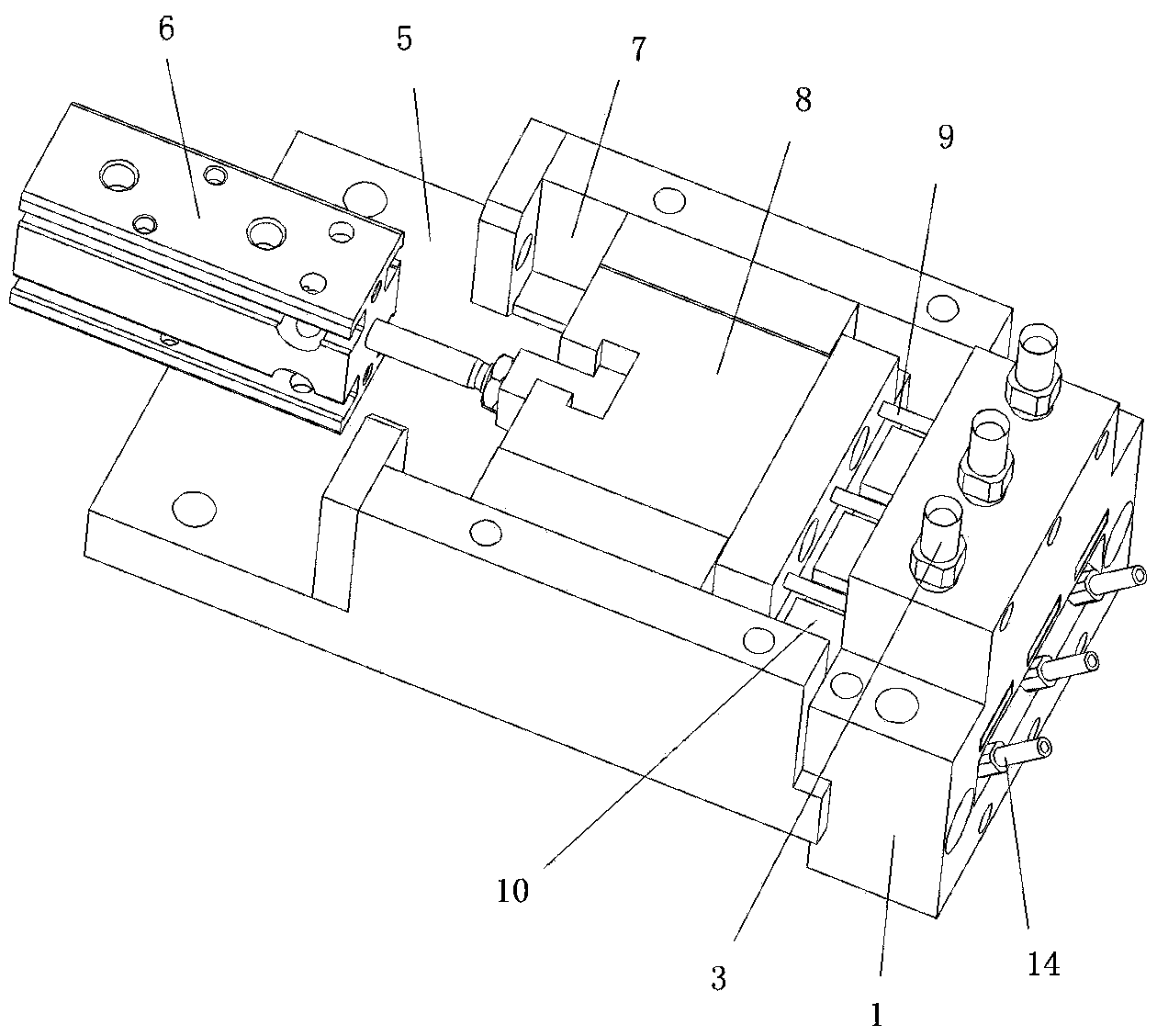

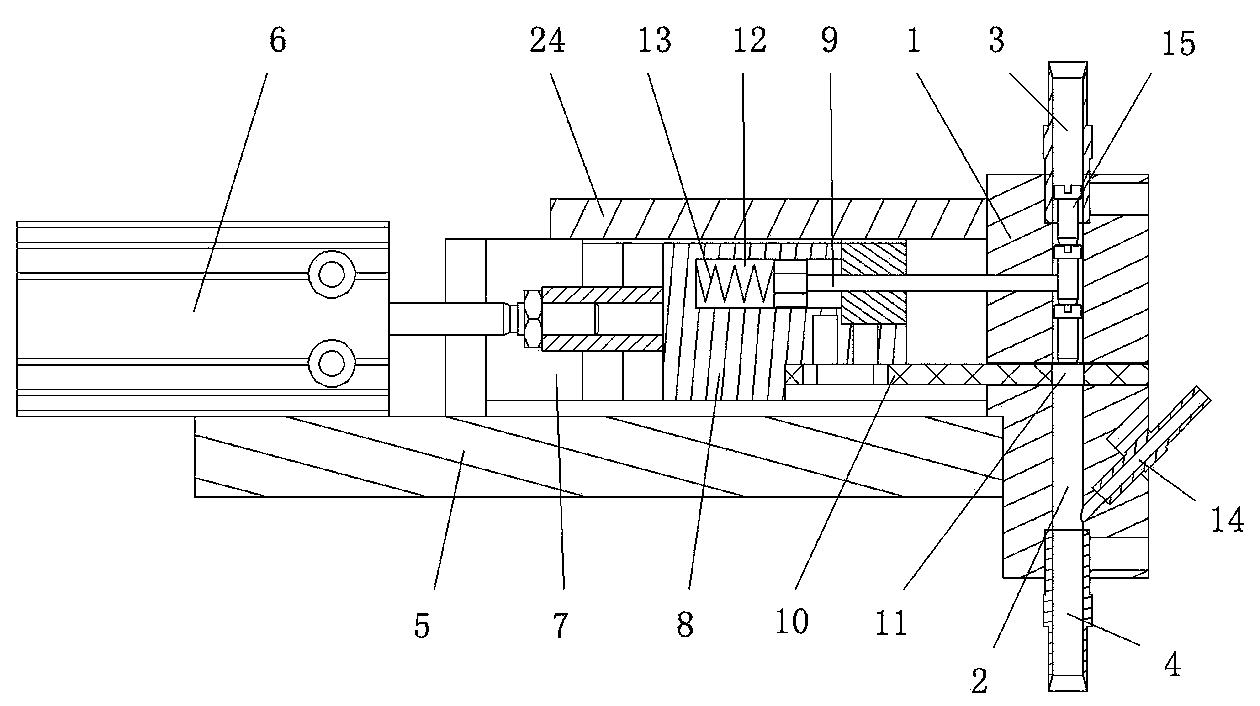

[0019] refer to figure 1 , figure 2 , a parts distribution device for automatic assembly equipment, comprising a base body 1, a plurality of distribution channels 2 are arranged in the base body 1, and the entrance of each distribution channel 2 is connected with a feed pipe 3, and each channel The outlets of the distribution channels 2 are all connected to a discharge pipe 4, and there is an angle between the axis of each distribution channel 2 and the horizontal line, and the side walls of each distribution channel 2 are arranged from top to bottom. The upper intercepting piece and the lower intercepting piece are arranged side by side, and the distance between the upper intercepting piece and the lower intercepting piece is a workpiece distance. in the distribution channel 2.

[0020] The interception driving mechanism includes a support 5 fixed on the base 1 and an interception cylinder 6 fixed on the support 5, the support 5 is provided with a chute 7, and the chute 7 ...

Embodiment 2

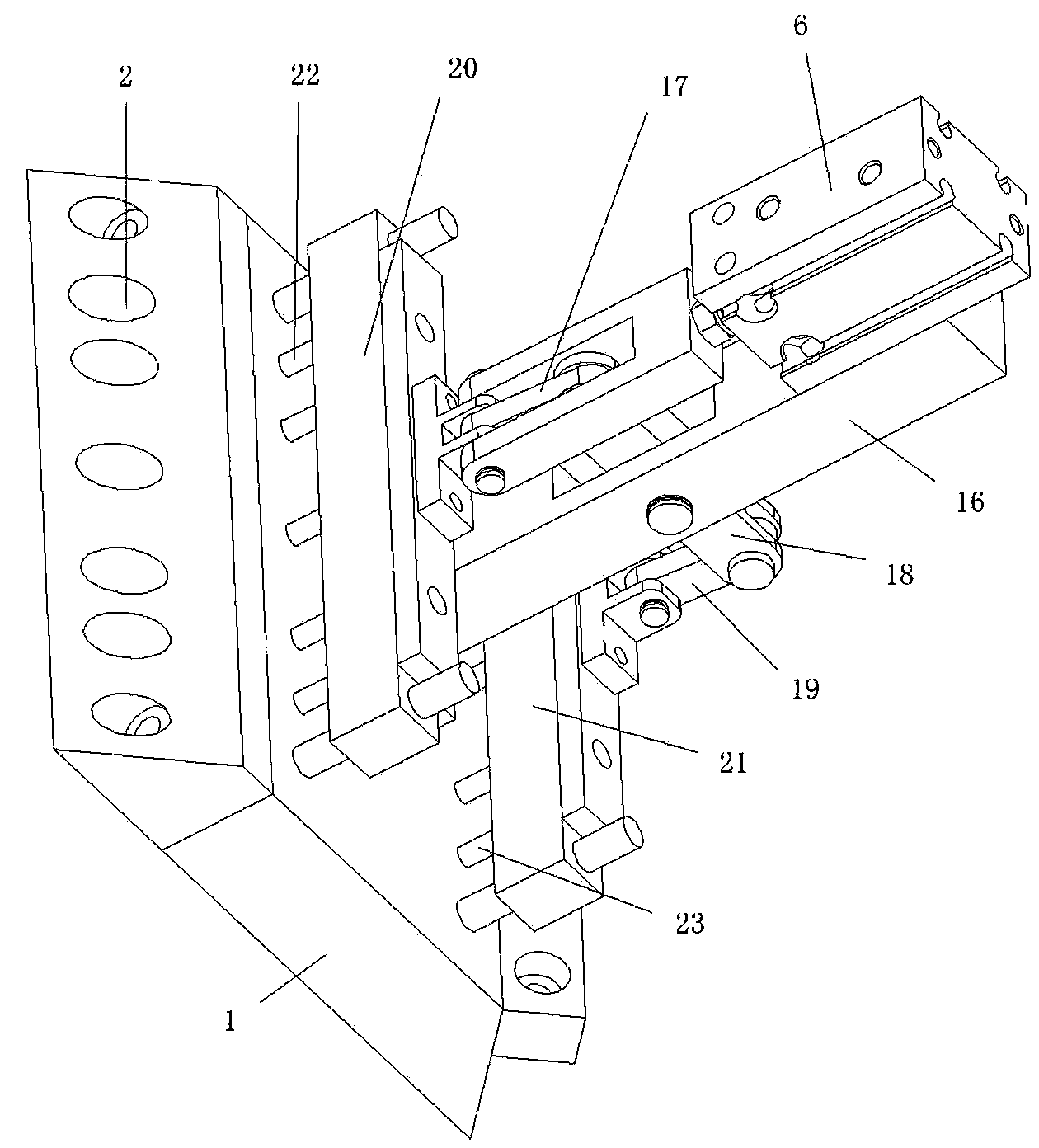

[0027] refer to image 3 , Figure 4 , a parts distribution device for automatic assembly equipment, comprising a base body 1, a plurality of distribution channels 2 are arranged in the base body 1, and the entrance of each distribution channel 2 is connected with a feed pipe 3, and each channel The outlets of the distribution channels 2 are all connected to a discharge pipe 4, and there is an angle between the axis of each distribution channel 2 and the horizontal line, and the side walls of each distribution channel 2 are arranged from top to bottom. The upper intercepting piece and the lower intercepting piece are arranged side by side, and the distance between the upper intercepting piece and the lower intercepting piece is a workpiece distance. in the distribution channel 2.

[0028] The intercepting drive mechanism includes a bracket 16 fixed on the base 1 and an intercepting cylinder 6 fixed on the bracket 16, and also includes an upper connecting rod 17, a middle con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com