All-weather railroad bridge detecting vehicle

A bridge inspection vehicle, all-weather technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of inspection time limit, safety accidents, poor inspection results, etc., and achieve the effect of smooth and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

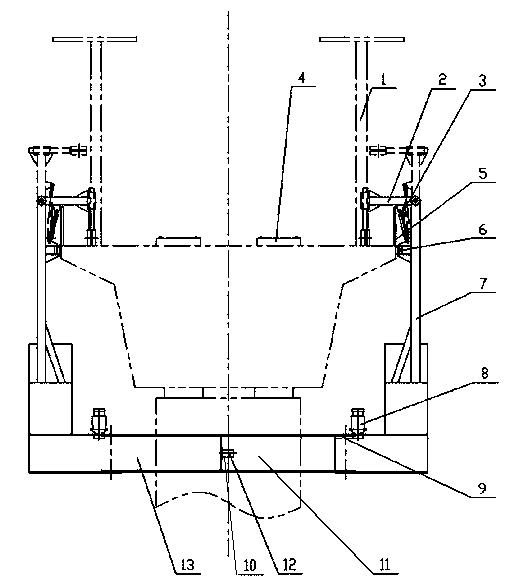

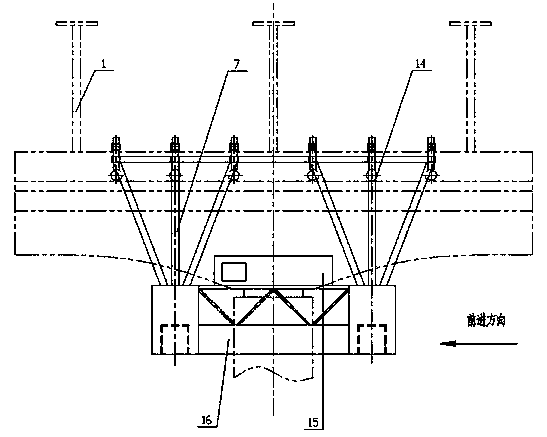

[0011] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] An all-weather railway bridge inspection vehicle of the present invention comprises two rows of walking legs 2 arranged side by side, the two rows of walking legs 2 are located outside the utility pole 1, and a wheel train is arranged below the walking legs 2 14. The two rows of walking wheel trains 14 are located between the track 4 and the sound insulation wall 5, and each of the walking legs 2 is hingedly connected to the structural support 7, and a drive is provided under each of the walking legs 2. The outrigger swing cylinder 3 for the horizontal swing of the walking outrigger 2, the outrigger swing cylinder 3 is arranged on the structural support 7, the lower end of each structural support 7 is connected to the power unit 16, and the power unit 16 A workbench 15 is arranged above the unit 16, and two swing beam group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com