Multilayered concentric type oil adsorption device and separator comprising same

An oil-gas separator, concentric technology, applied in the field of accessories of air compressor units or refrigeration compressor units, can solve problems such as increased maintenance costs, low oil separation efficiency, clogging of oil filter elements, etc., to achieve simplified structure, good effect, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

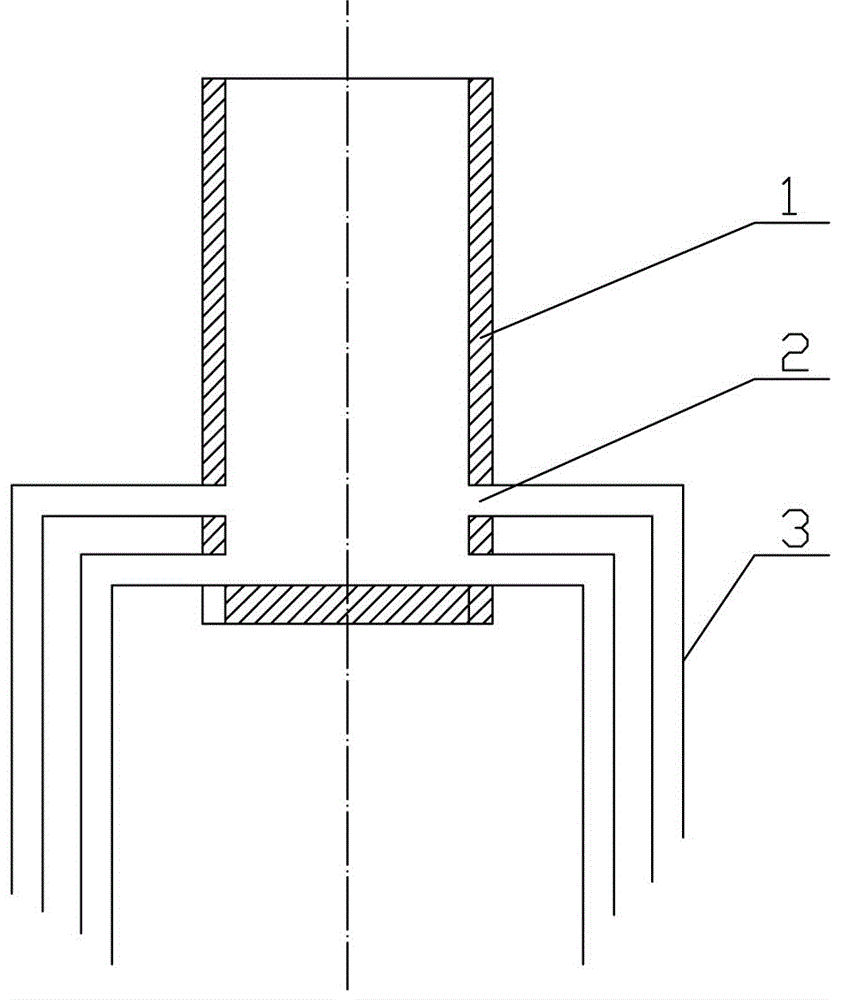

[0022] Such as figure 1 As shown, a multi-layer concentric oil attachment is provided with several groups of uniformly distributed gas distribution holes 2 on the outer circumference of the gas distribution conduit 1, and the axes of the gas distribution holes 2 of the same group are located on the same horizontal plane; The outer wall of 1 is coaxially provided with a number of coaxial oil attachment tubes 3 with openings downward, every two adjacent oil attachment tubes 3 form a group, and one of the air holes 2 is located in the group of oil attachment tubes 3 formed in the annular cavity. The more groups of air distribution holes and corresponding oil attachment cylinders, the better the effect of oil and gas separation.

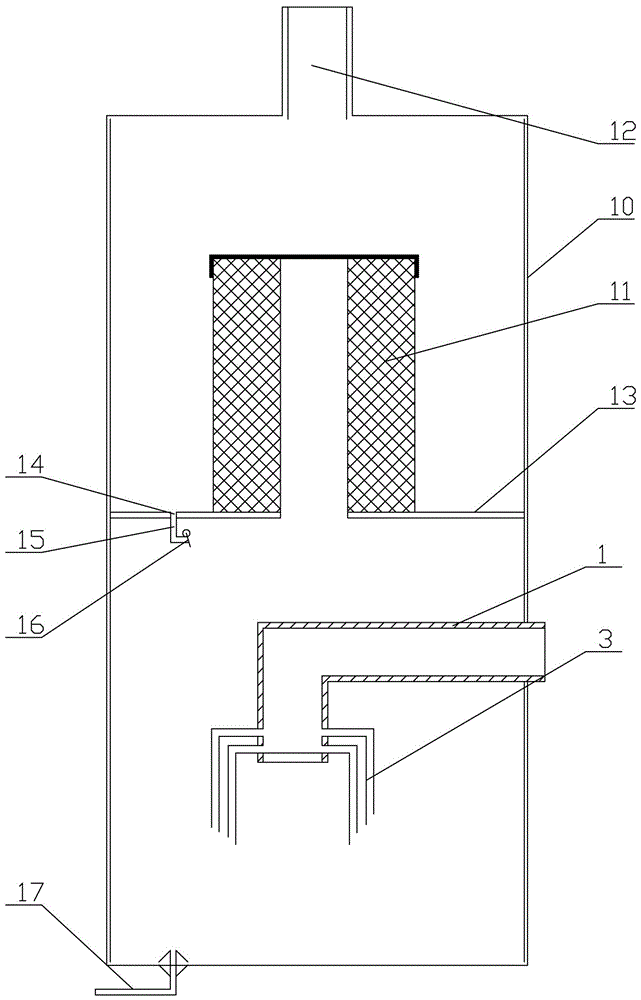

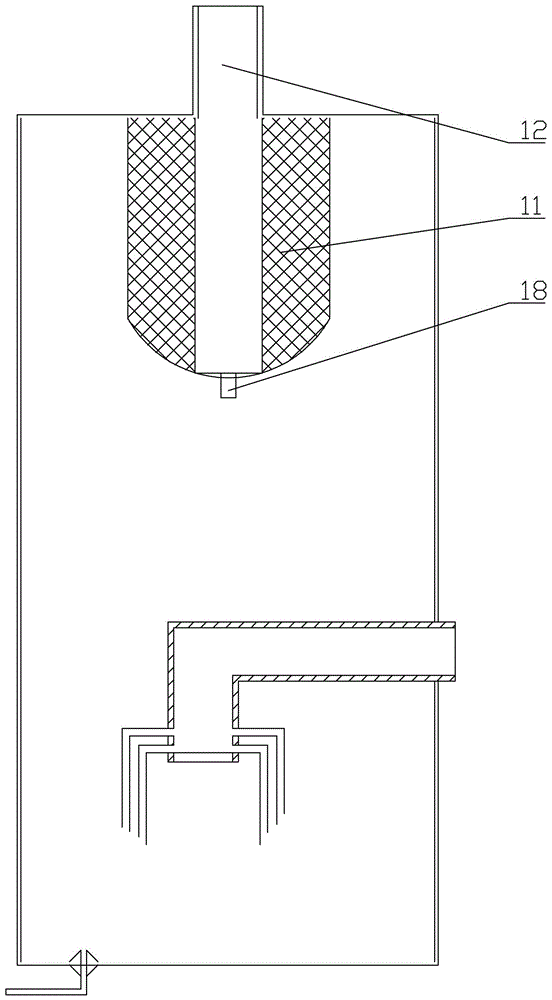

[0023] Such as figure 2 As shown, the first embodiment of the oil-gas separator containing the oil attacher is provided with a multi-layer concentric oil attacher in the lower half of the cavity of the casing 10, and the inlet of the gas distribution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com