Automatic clearance compensation type efficient sealing device

A gap compensation and sealing device technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of aggravated oil mist and oil droplet overflow, hidden dangers of safe and civilized production, and no compensation amount, etc., to improve the sealing effect, The effect of reducing friction coefficient and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

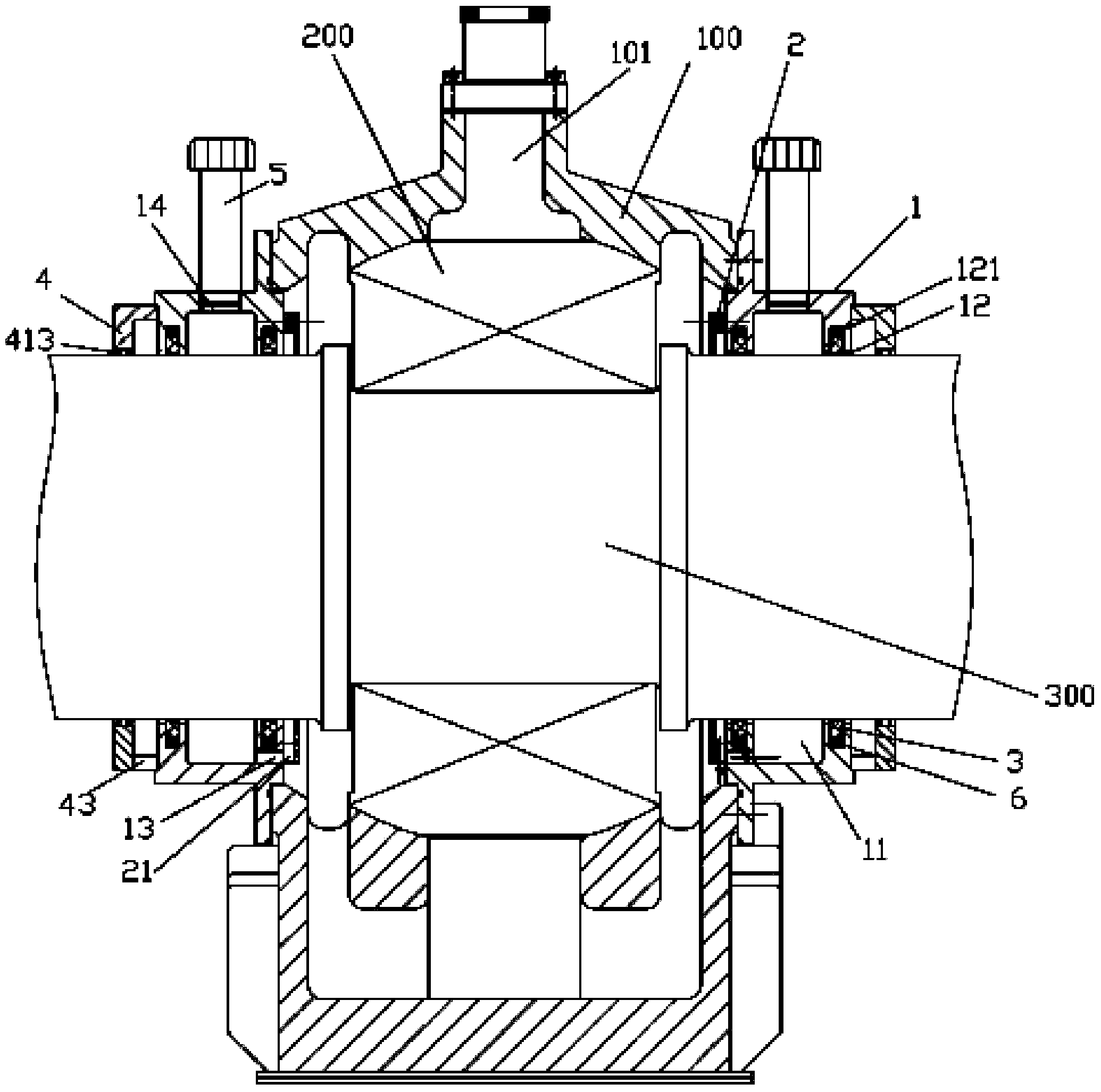

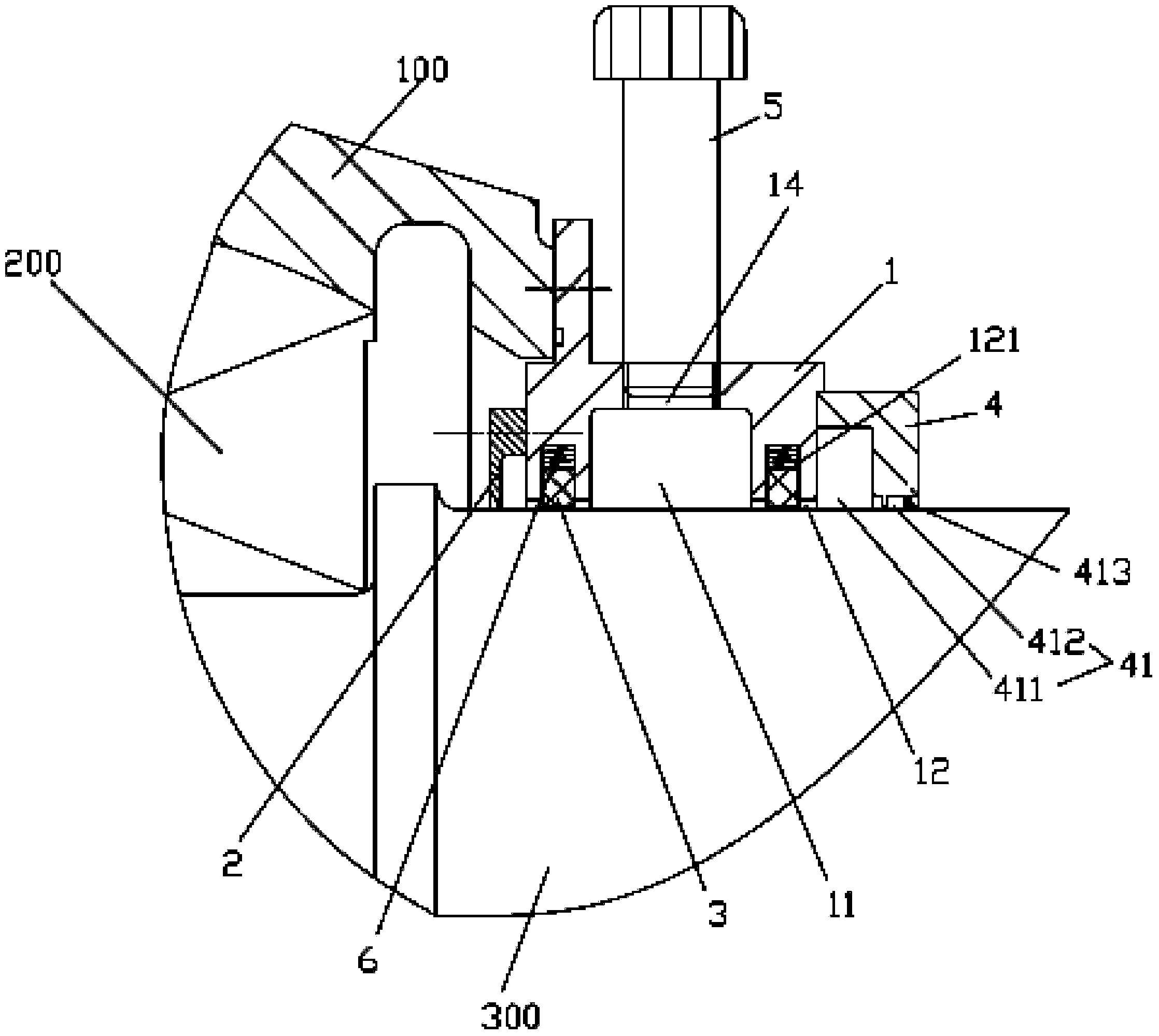

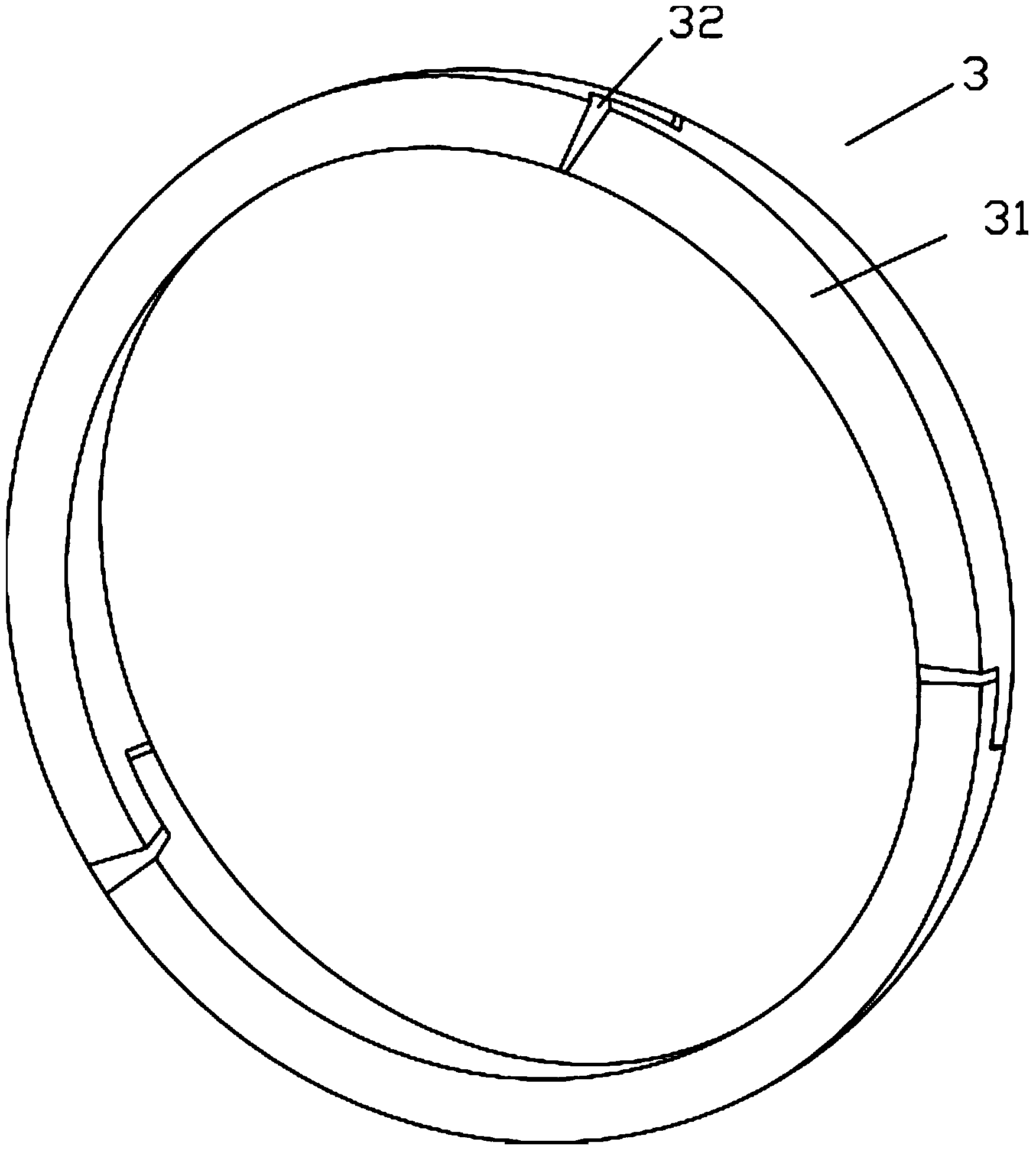

[0023] Examples, see e.g. Figures 1 to 4 As shown, a high-efficiency sealing device for automatic clearance compensation includes a bearing housing 100, bearing end covers 1 are fixed at both ends of the bearing housing 100, a bearing 200 is installed in the bearing housing 100, and the middle part of the rotating shaft 300 is fixed on the center of the bearing 200. On the inner wall, both ends of the rotating shaft 300 are inserted and sleeved on the bearing end cover 1, and the end surface of the bearing end cover 1 close to the bearing 200 is fixed with an oil retaining cover 2, and the rotating shaft 300 is inserted and sleeved in the oil retaining cover 2 A cavity 11 is formed in the middle of the bearing end cover 1, a circular through hole 12 is formed at both ends of the bearing end cover 1, an inner groove 121 is formed on the inner side wall of the circular through hole 12, and an inner groove 121 is formed in the inner groove 121. The sleeve has a sealing ring 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com