Sf6 equipment micro water test special joint device

A SF6, micro-water technology, used in mechanical equipment, pipes/pipe joints/fittings, connections with fluid cut-off devices, etc. Uniform shape, reasonable structure design, simple and convenient connection and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

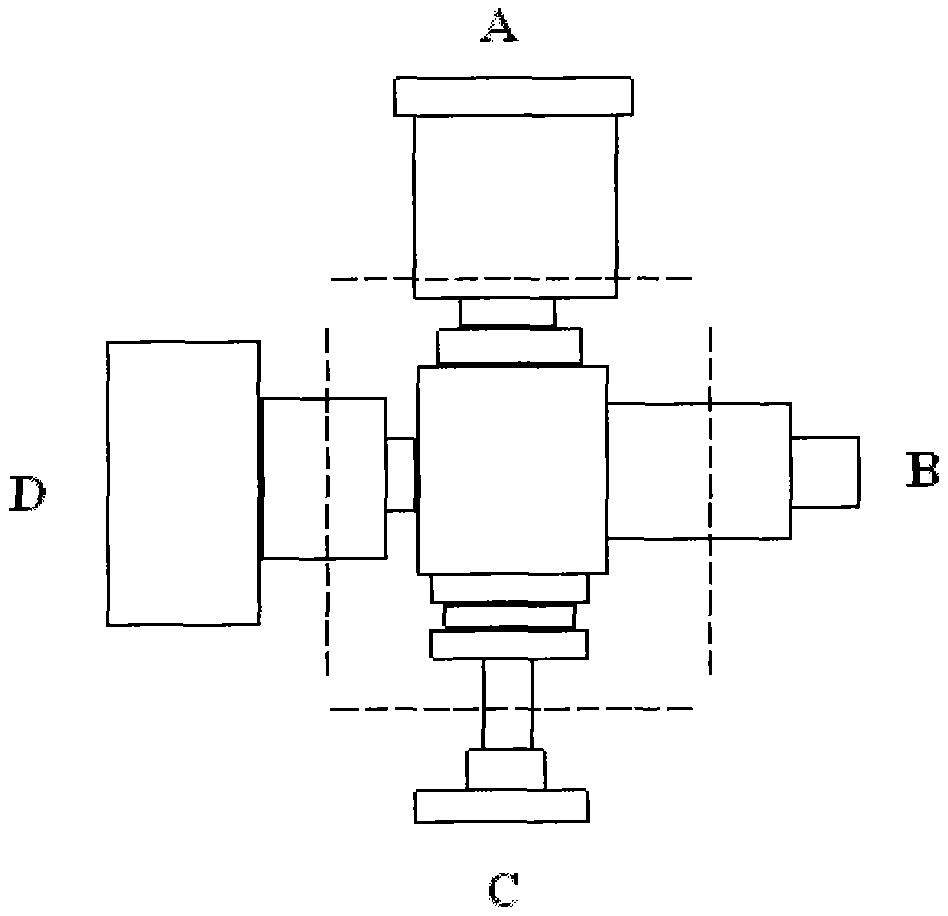

[0015] refer to figure 1 , the SF6 equipment micro-water test special joint of the present invention is in the form of a four-way valve and includes four functional areas: pressure display end A, test instrument hose interface end B, check valve end C, and equipment connection port end D. There is a chamber inside the special joint for micro-water testing, the top of the chamber is fixedly connected to the pressure display end A, the bottom is threaded to the check valve end C, and one of the left and right sides is connected to the test instrument hose interface end B , the other side of the left and right sides is connected to the equipment connection port D, the pressure display end A is opposite to the check valve end C, and the test instrument hose interface B is opposite to the equipment connection port D.

[0016] The pressure display terminal A is a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com