Range hood

The technology of a range hood and an oil collecting plate is applied in the field of kitchen and bathroom, which can solve the problems of difficult cleaning and a large amount of oil pollution, and achieve the effects of improving the flow speed and evenly distributing the suction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

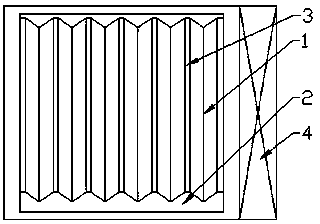

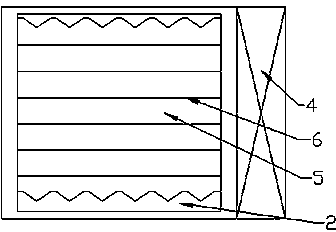

[0014] like Figure 1~2 As shown, a range hood includes an air extraction cavity, a shroud, an oil collecting plate and an air extraction fan 4, the air extraction fan 4 is arranged in the air extraction cavity, and the oil collector is arranged in the air extraction cavity On the end face of the air cavity, the deflector 1 is arranged on the back of the deflector, which is characterized in that: the deflector includes an outer frame 2, several deflectors 1, and an oil collection tank;

[0015] The deflectors 1 are fixed in the outer frame 2 in a parallel array, gaps 3 are provided between the deflectors 1, the oil collection tank is arranged at the bottom of the outer frame 2, the top of the oil collection tank is open, and the deflector 1 Thread through opening into oil sump.

[0016] The deflector 1 is a prismatic plate, the cross section of the deflector 1 is triangular, and one side of the triangle is parallel to the oil collecting plate.

[0017] The range hood also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com