Method and sliding form for producing a structure and corresponding structure

A technology of building structure and sliding formwork, which is applied in the field of manufacturing sliding formwork of building structures and tower building structures such as wind energy equipment towers. It can solve the problems of increasing the cost of WEA towers, and achieve high scalability, efficient overall structure, Improve the effect of solidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

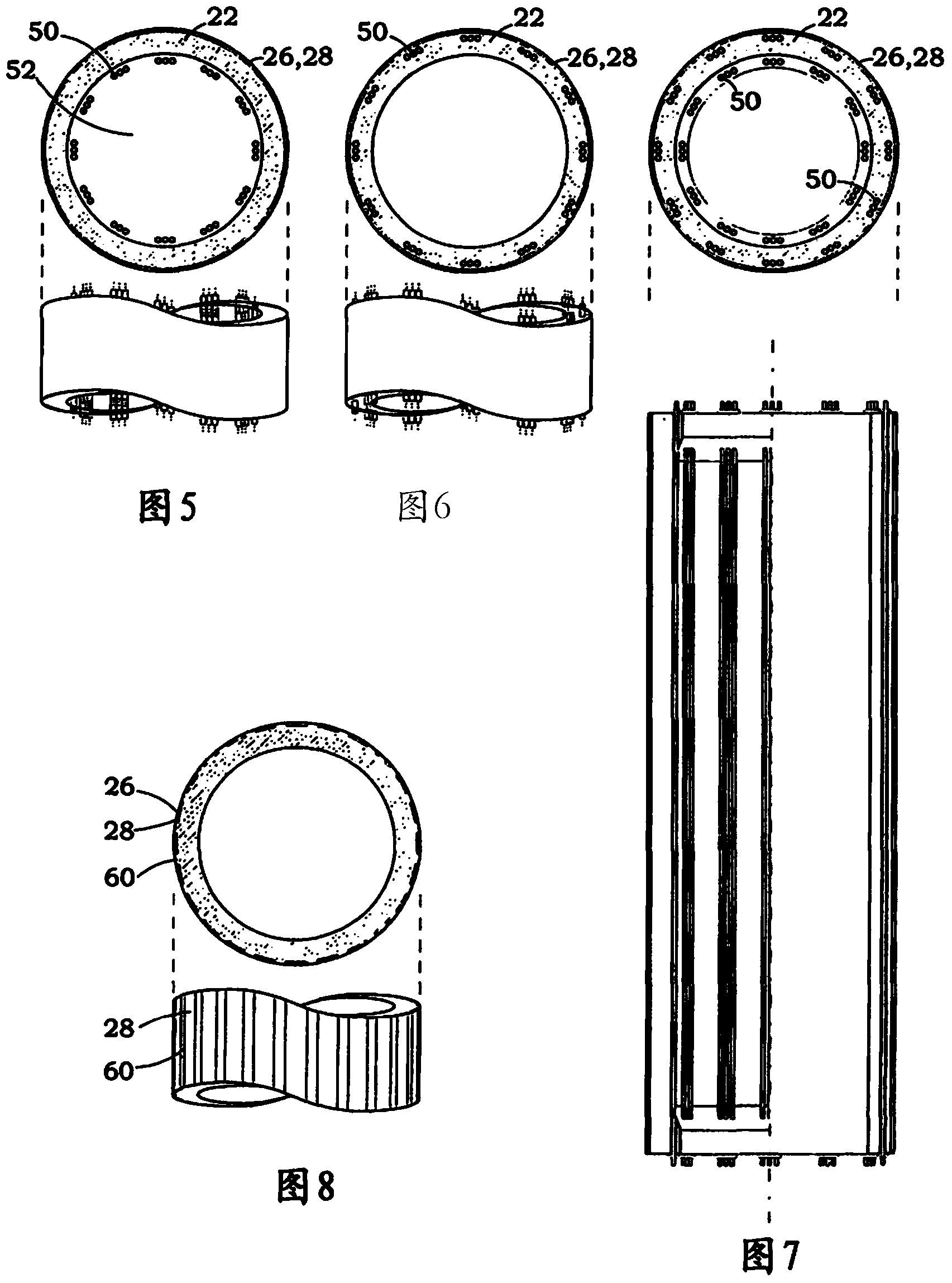

[0084] exist figure 1 In , the load-bearing building structure is shown in the form of a wind energy installation tower 10 , which is embodied as a hybrid tower, however, this is not to be regarded as restrictive for the building structure. In the case of the wind energy installation shown here, the building structure has a concrete hollow body 14 based on the foundation 12 , which has a height of at least 90 m, in particular at least 130 m. A steel tower 16 is mounted on the concrete hollow body 14 , which supports a nacelle 18 .

[0085] The concrete hollow body 14 can be produced in one piece or consist of a plurality of parts which can be placed one above the other and possibly connected to each other. In this case, the concrete hollow body preferably has a minimum length of 10 m and is an elongated body.

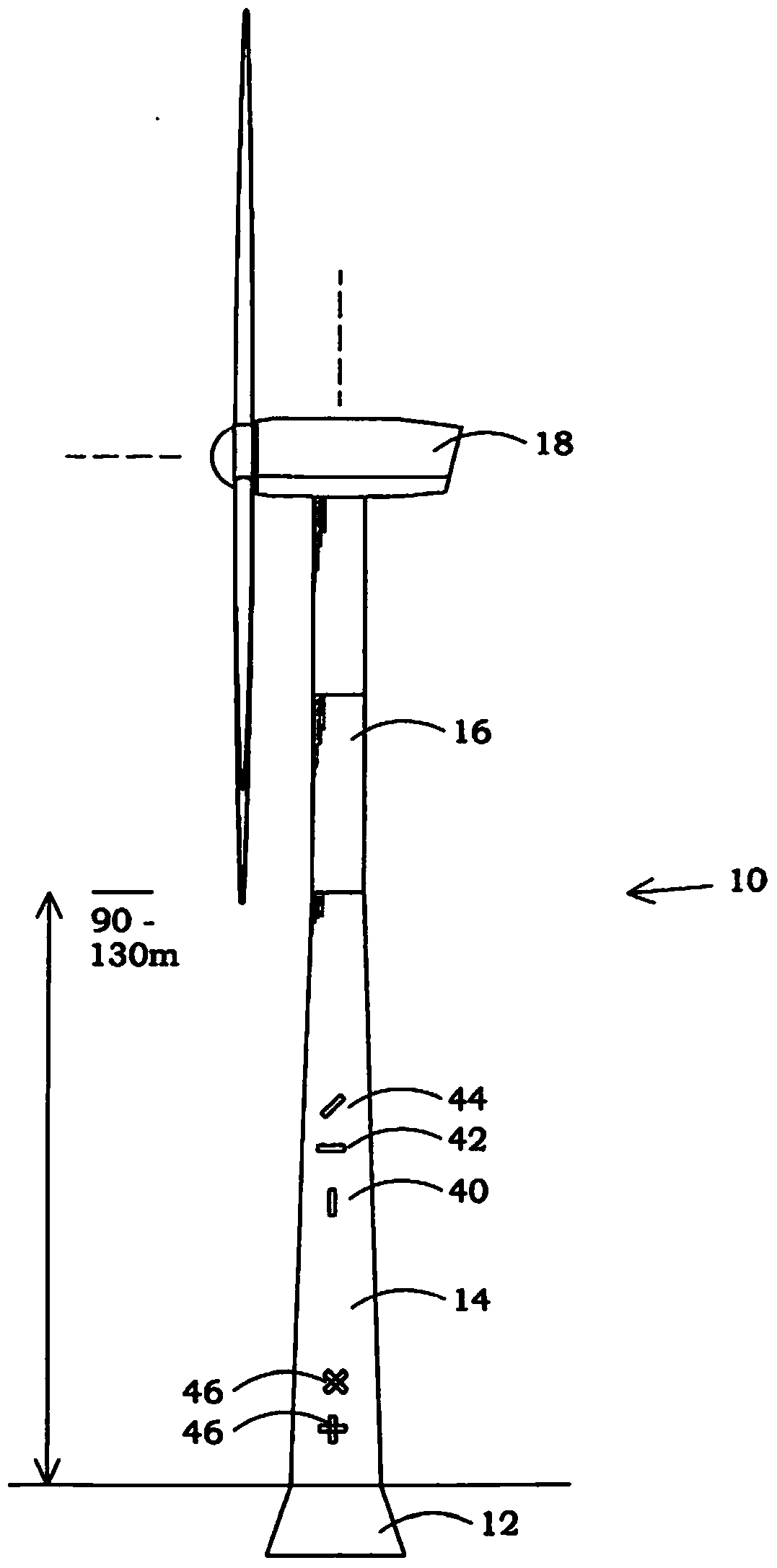

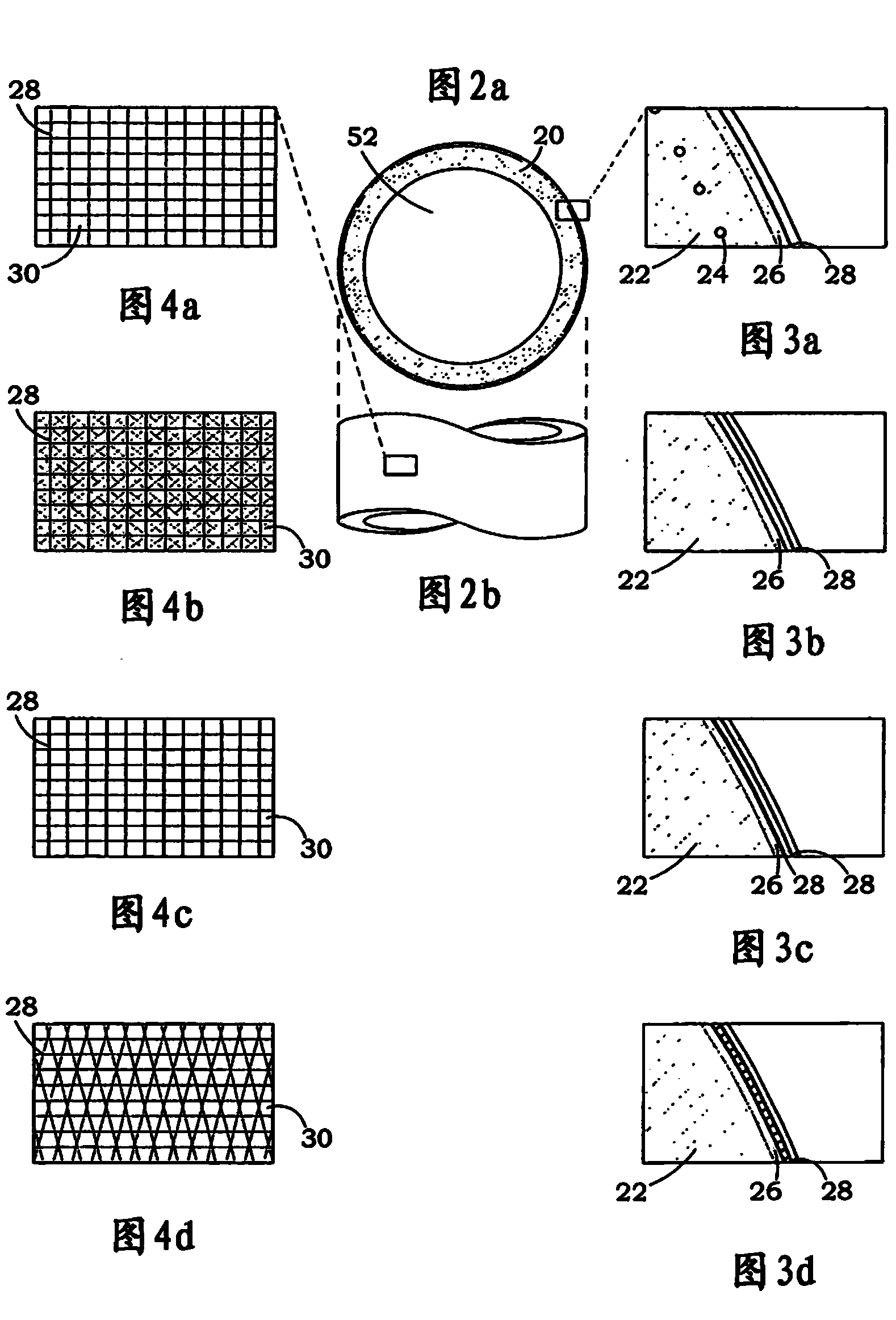

[0086] Figure 2aA section is shown through a concrete hollow body 14 , which is embodied as a cylinder, preferably a linear cylindrical cylinder.

[0087] The conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com