High-strength gear processing technology

A technology of high-strength gears and processing technology, which is applied in the direction of gears, manufacturing tools, and other manufacturing equipment/tools. It can solve the problems that the strength of a single tooth cannot be achieved, and achieve good core toughness, hard surface hardness, and material grain structure. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

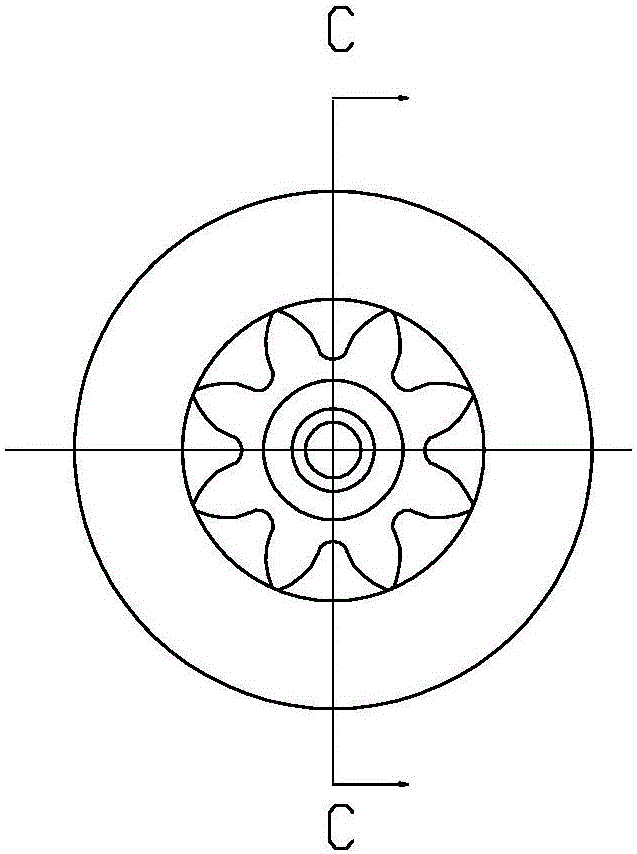

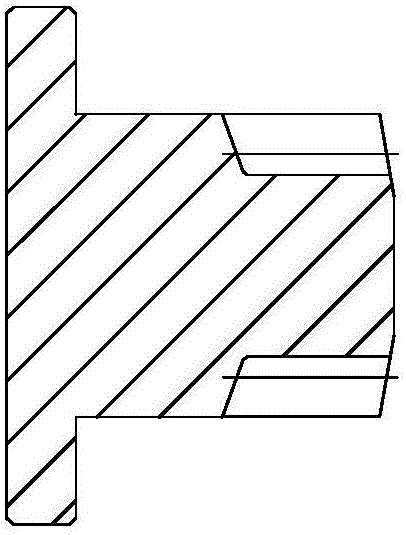

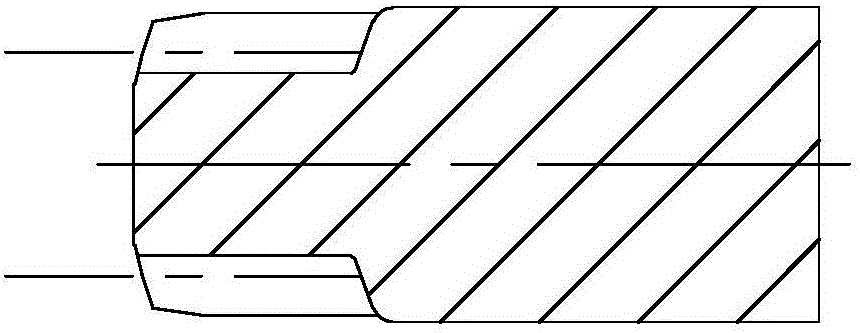

Image

Examples

Embodiment 1

[0025] Embodiment 1: a high-strength gear processing technology, including the following process steps:

[0026] (1) 20CrMnTi alloy steel round blanks are selected as raw materials, which have high strength and toughness, and relatively good hardenability. After carburizing, quenching and tempering, the surface is hard and the core has good toughness;

[0027] (2) Grinding the outer circle: removing fine cracks on the surface of the round billet and improving the surface finish;

[0028] (3) Annealing: Treat the round billet at a temperature of 870°C for 10 hours, then cool it to 360°C with the furnace, and take it out of the furnace; the function of annealing is to soften the metal;

[0029] (4) Shot blasting: After the round billet is annealed, it is shot blasted for 10 minutes to remove residual substances on the surface of the round billet, such as scale, etc.;

[0030] (5) Surface treatment: Treat the round billet in phosphating solution and saponification solution respe...

Embodiment 2

[0037] Embodiment 2: A high-strength gear processing technology, comprising the following process steps:

[0038] (1) 20CrMnTi alloy steel round blanks are selected as raw materials, which have high strength and toughness, and relatively good hardenability. After carburizing, quenching and tempering, the surface is hard and the core has good toughness;

[0039] (2) Grinding the outer circle: removing fine cracks on the surface of the round billet and improving the surface finish;

[0040] (3) Annealing: Treat the round billet at a temperature of 890°C for 8 hours, then cool it to 360°C with the furnace, and then take it out of the furnace; the function of annealing is to soften the metal;

[0041] (4) Shot blasting: After the round billet is annealed, it is shot blasted for 15 minutes to remove residual substances such as scale on the round billet surface;

[0042] (5) Surface treatment: Treat the round blank in phosphating solution and saponification solution respectively to...

Embodiment 3

[0049] Embodiment three: a high-strength gear processing technology, including the following process steps:

[0050] (1) 20CrMnTi alloy steel round blanks are selected as raw materials, which have high strength and toughness, and relatively good hardenability. After carburizing, quenching and tempering, the surface is hard and the core has good toughness;

[0051] (2) Grinding the outer circle: removing fine cracks on the surface of the round billet and improving the surface finish;

[0052] (3) Annealing: Treat the round billet at a temperature of 880°C for 9 hours, then cool it to 370°C with the furnace, and then take it out of the furnace; the function of annealing is to soften the metal;

[0053](4) Shot blasting: After the round billet is annealed, it is shot blasted for 12 minutes to remove residual substances such as oxide skin on the surface of the round billet;

[0054] (5) Surface treatment: Treat the round blank in phosphating solution and saponification solution r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com