Single track high-efficiency automatic blow molding machine

A single-track, blow molding machine technology, applied in the field of single-track high-efficiency automatic blow molding machines, can solve the problems of complex blow mold template design, complex mechanism, and affecting blow molding machine blowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

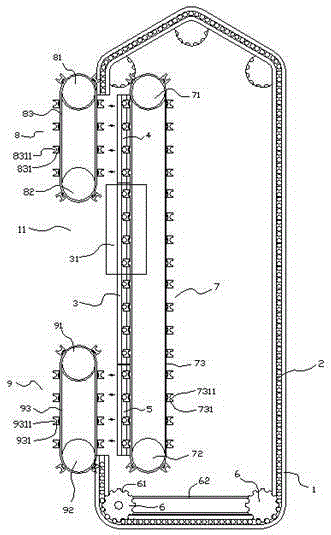

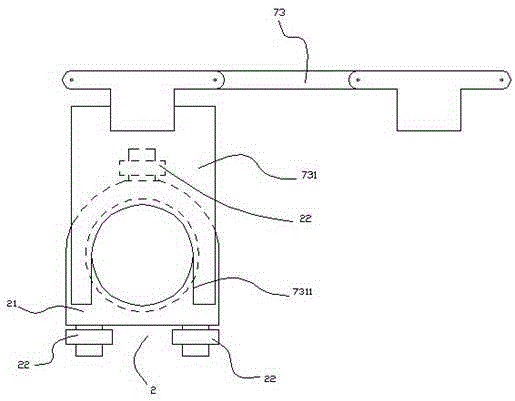

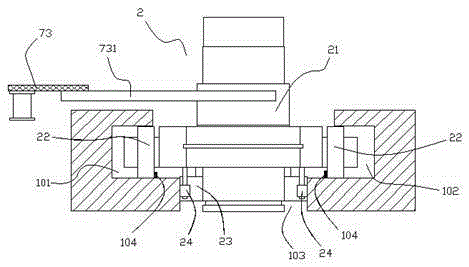

[0022] Such as Figure 1-3 As shown, a single-track high-efficiency automatic blow molding machine includes a working track 1 for the cyclic movement of the preform seat 2. The working track 1 is provided with a gap 11 at a certain straight line position. The inside of the gap 11 or The blowing track 3 with a length shorter than the notch 11 and a linear layout is arranged side by side at a distance from the outside. inside.

[0023] The two ends of the blowing track 3 are respectively provided with a feeding moving track 4 and a reset moving track 5, and the feeding moving track 4 and the reset moving track 5 can be moved outwards to be connected with the two ends of the gap 11 of the working track 1 respectively. connect.

[0024] The two corners of the working track 1 are respectively provided with a preform seat driving turntable 6 with a bayonet 61. During work, the preform seat 2 is placed on the working track by the rotation of the above two driving turntables 6. 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com