Double sheet detection device

A detection device and thickness measurement technology, applied in the directions of transportation and packaging, object supply, pile separation, etc., can solve the problems of wasting paper, time-consuming and laborious, defective products of two cover books, etc., so as to save the calibration thickness and shorten the reset time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

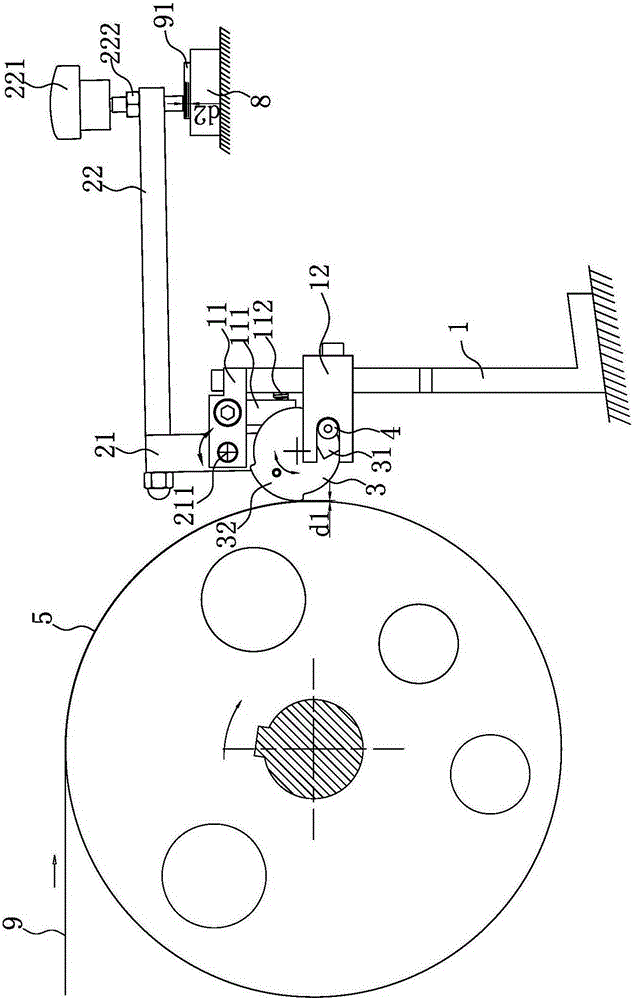

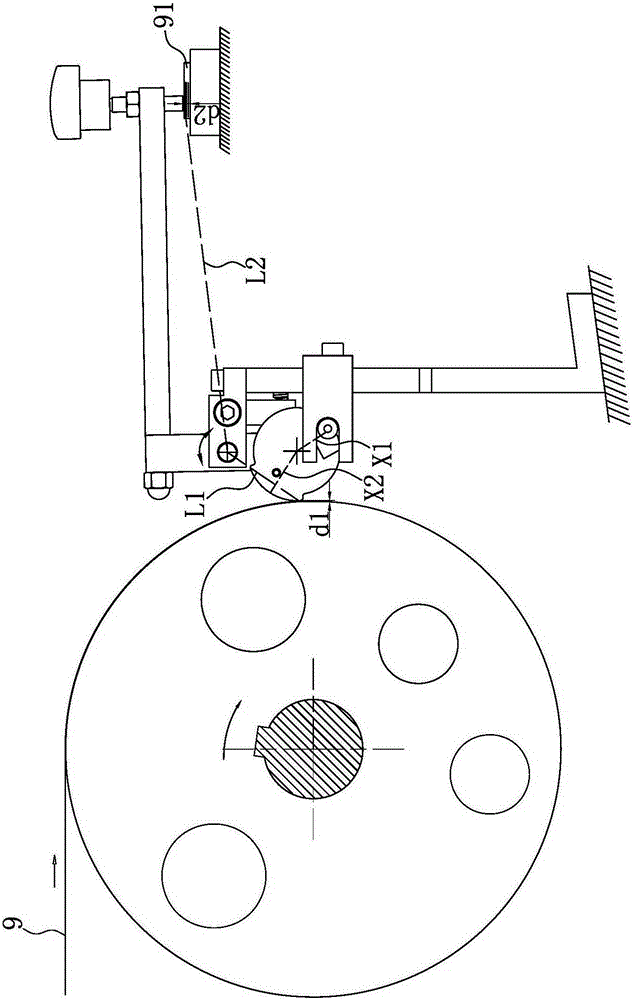

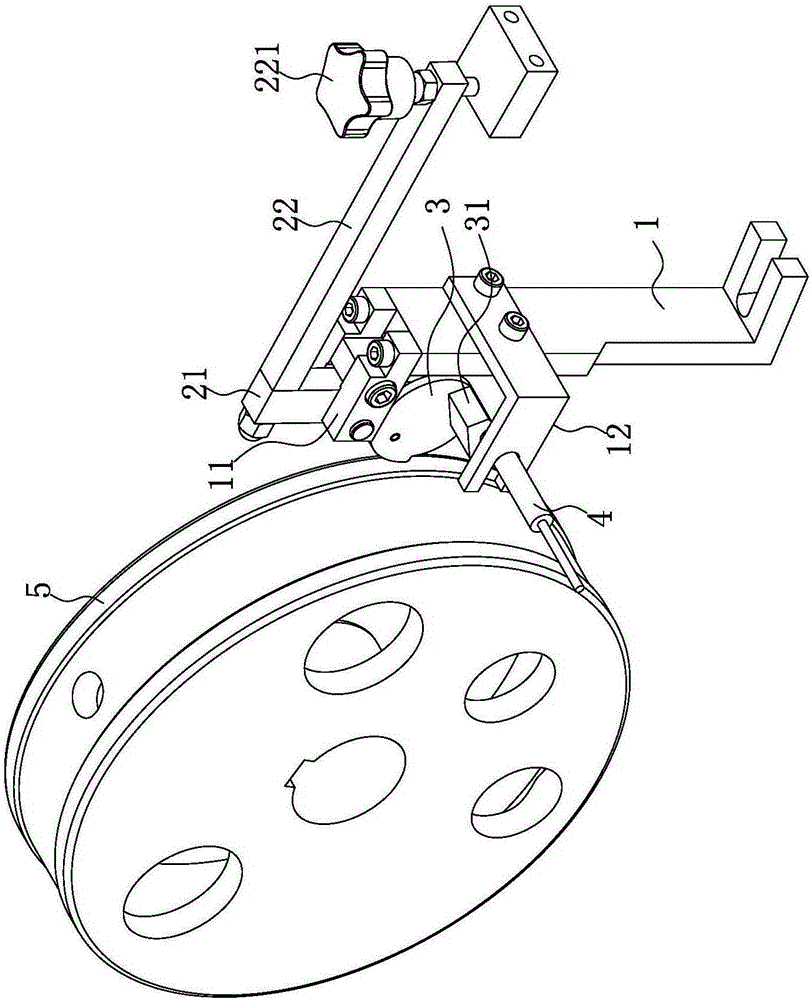

[0019] Such as Figure 1-Figure 7 As shown, the double sheet detection device of the present invention includes a bracket 1 , a left lever 21 , a right lever 22 , a thickness measuring wheel 3 , a photoelectric sensor 4 and a paper biting wheel 5 .

[0020] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a bracket 1 is provided on one side of the circumferential surface of the biting wheel 5 . Described support 1 is vertical direction, and support 1 top is fixedly connected with the right part of support upper rod 11, and the left part of support upper rod 11 is hingedly connected with left lever 21 by axle 211. A compression spring 112 is provided between the bracket 1 and the left lever 21 . The compression spring 112 is located on the lower side of the shaft 211 . The middle part of the upper rod 11 of the support is fixedly connected with the upper part of the clip spring guide rail 111 . The compression spring 112 passes through the through hole in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com