Lead zirconate titanate pyroelectric ceramic material and preparation method thereof

A technology of pyroelectric ceramics and lead zirconate titanate, which is applied in the field of lead zirconate titanate pyroelectric ceramic materials and its preparation, can solve the problems of low pyroelectric coefficient, high dielectric loss, and large dielectric constant. Achieve the effect of high pyroelectric coefficient, low dielectric constant and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

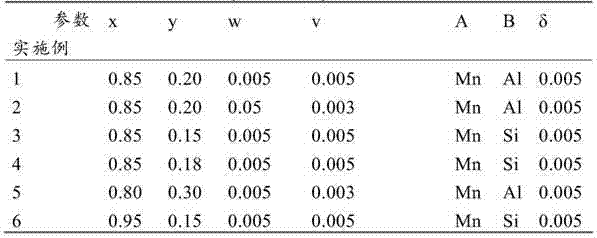

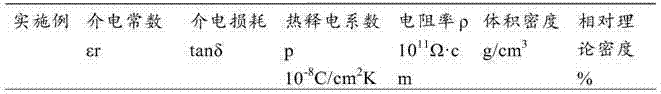

Examples

Embodiment 1

[0019] Embodiment 1 (Pb 1.005 )(Fe 1 / 2 Nb 1 / 2 ) 0.20 (Zr 0.85 Ti 0.15 ) 0.80 o 3 +0.5at.%Mn+0.5at.%Al

[0020] Weigh Pb according to the stoichiometric ratio 3 o 4 , ZrO 2 、TiO 2 , Fe 2 o 3 , Nb 2 o 5 , MnCO 3 and Al 2 o 3 For the raw material powder, add 0.8 times the total weight of the raw material in deionized water, and ball mill and mix for 24 hours (wherein, the weight ratio of powder:ball:water is 1:1.5:0.8), so that the components are mixed evenly. Dry it, add 10wt.% deionized water and compact it, raise the temperature to 830°C at a rate of 2°C / min and keep it warm for 2 hours to obtain a ceramic powder.

[0021] Crush the ceramic powder, pass through a 30-mesh sieve, and then use wet ball milling for 24 hours (wherein the weight ratio of powder: ball: water is 1:2:0.4), dry the powder, and then add 6wt. %PVA binder; granulation, aging for 24 hours, passing through a 30-mesh sieve, pre-pressing and then 0.8MPa isostatic pressing, and discharging at...

Embodiment 2

[0023] Embodiment 2 (Pb 1.005 )(Fe 1 / 2 Nb 1 / 2 ) 0.20 (Zr 0.85 Ti 0.15 ) 0.80 o 3 +5.0at.%Mn+0.3at.%Al

[0024] The preparation method of Example 1 was repeated according to the above formula, except that the sintering temperature was 1100° C., and other conditions remained unchanged.

Embodiment 3

[0025] Embodiment 3 (Pb1.005 )(Fe 1 / 2 Nb 1 / 2 ) 0.15 (Zr 0.85 Ti 0.15 ) 0.85 o 3 +0.5at.%Mn+0.5at.%Si

[0026] The preparation method of Example 1 was repeated according to the above formula, except that the sintering temperature was 1250° C., and other conditions remained unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com