A light and stable connection structure of prefabricated building wall beams

A connection structure and prefabricated technology, applied in the direction of building structure, construction, etc., can solve the problems of unsatisfactory anti-seismic effect, complex structure structure, self-weight of connection nodes, etc., to reduce the additional effect of gravity, the overall force is reasonable, and the self-weight is reduced Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

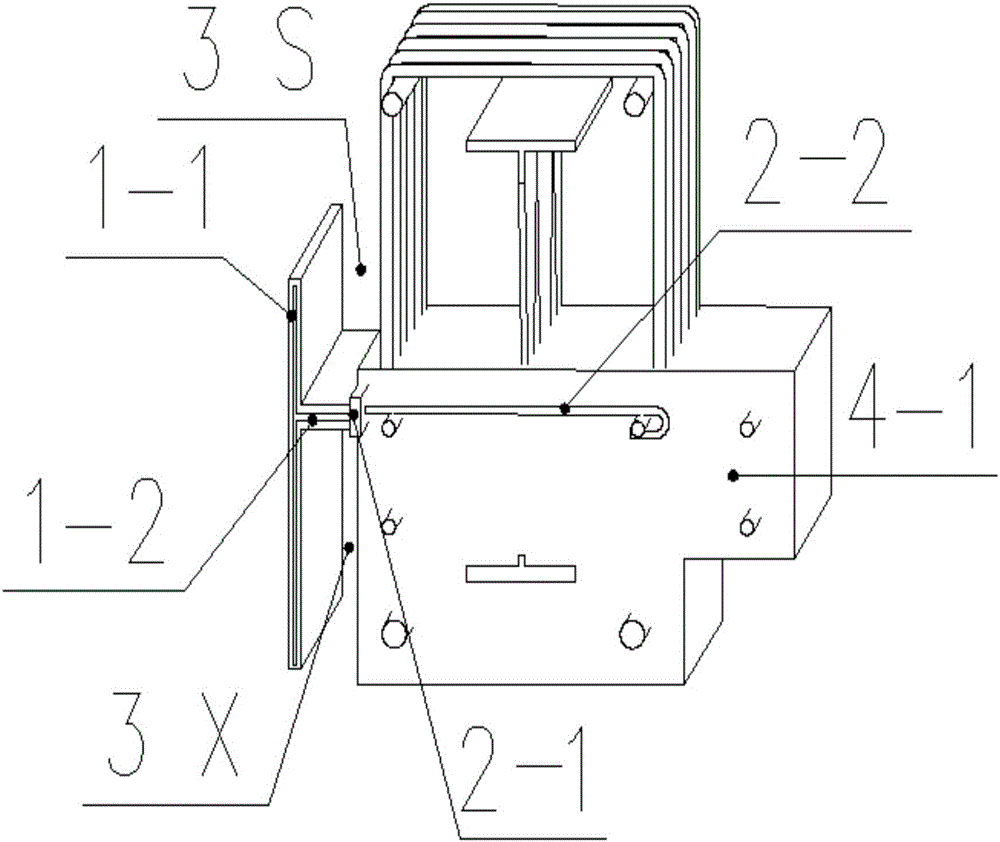

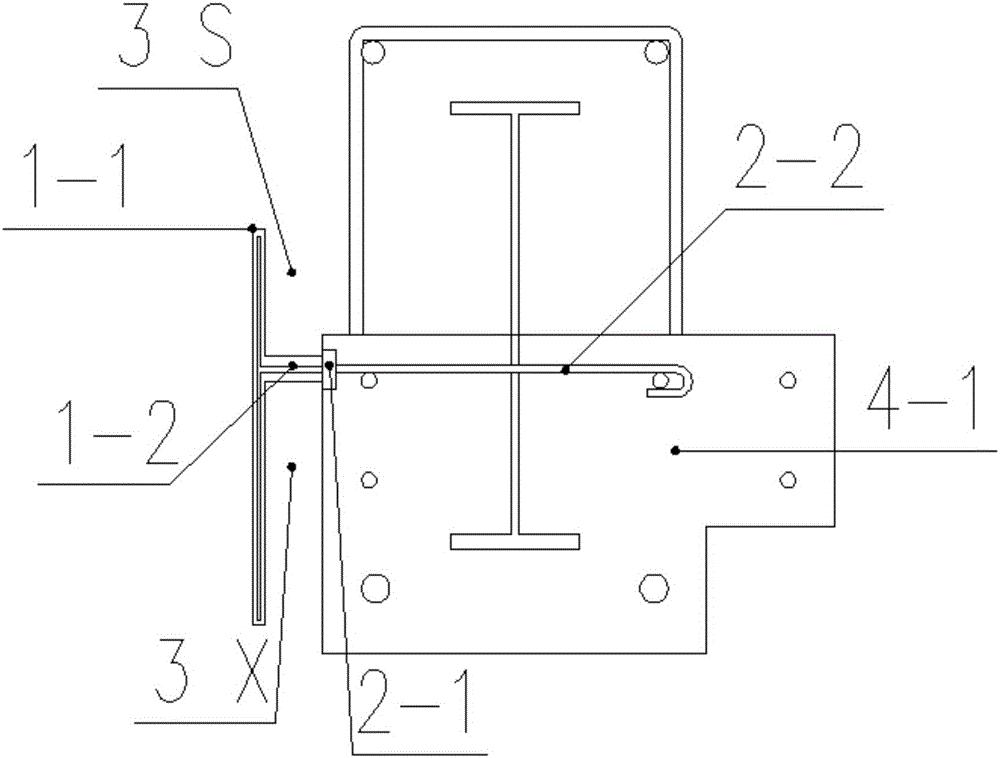

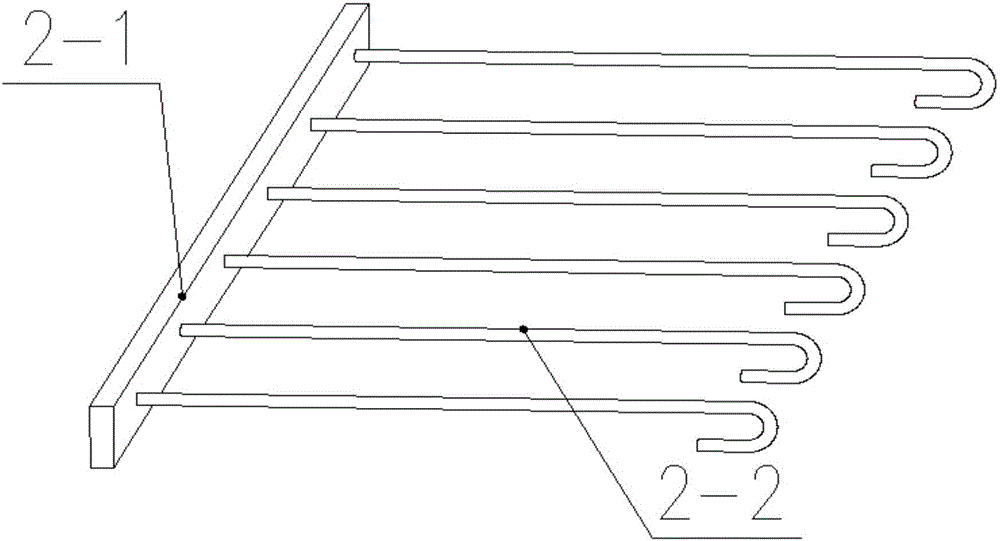

[0016] The present invention is a light-weight and stable connection structure for prefabricated building wall beams, which is composed of laminated beams, prefabricated wall panels, connecting members, and pre-embedded connecting rows. It consists of a longitudinal long seat 2-1 and a horizontal row of rods 2-2 on one side. The pre-embedded connecting row is pre-embedded longitudinally in the lower steel reinforced concrete prefabricated beam 4-1 of the composite beam, and the side of the longitudinal seat 2-1 The side is exposed on the top side of the lower prefabricated beam, and the long T-shaped glass fiber reinforced concrete connecting member is placed horizontally, and the end of the horizontal connecting surface 1-2 is fixedly connected with the longitudinal seat 2-1 of the pre-embedded connecting row. Between the vertical connection surface 1-1 of the type glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com