High-voltage circuit breaker mechanical failure diagnosis method based on vibration signal analysis

A technology for high-voltage circuit breakers and mechanical faults, which is used in vibration measurement, testing of mechanical components, vibration measurement in solids, etc. It can solve the problems of low judgment accuracy of circuit breakers and too simple criteria, so as to prevent the development of faults and facilitate the Intuitive effect of maintenance work and judgment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

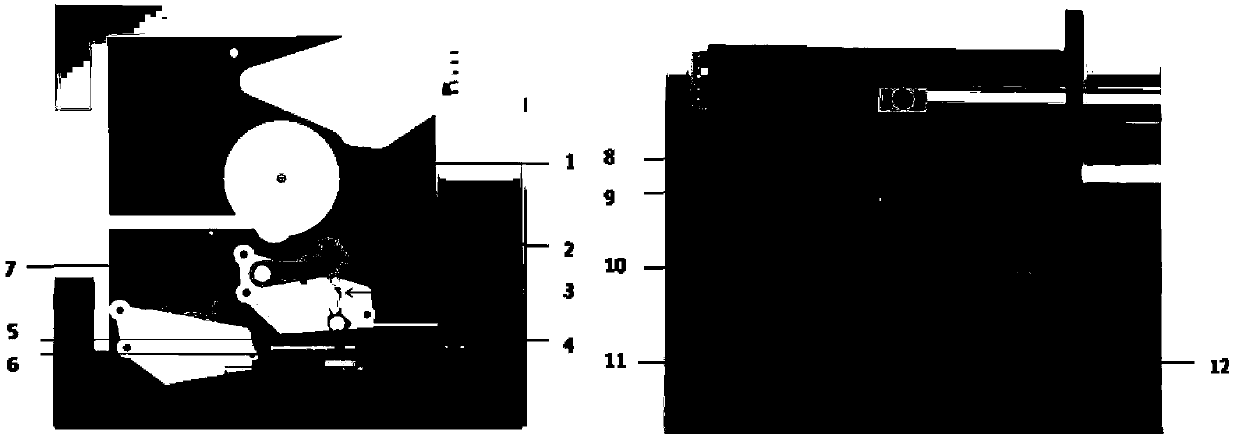

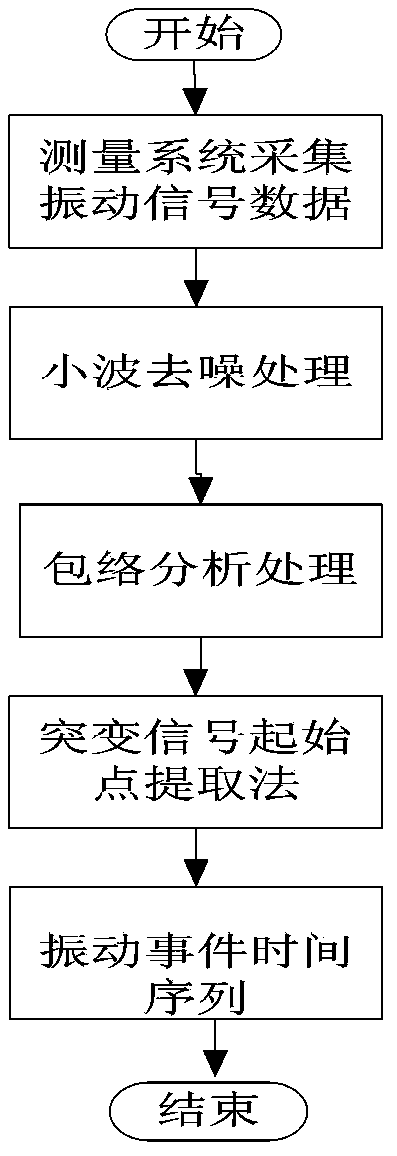

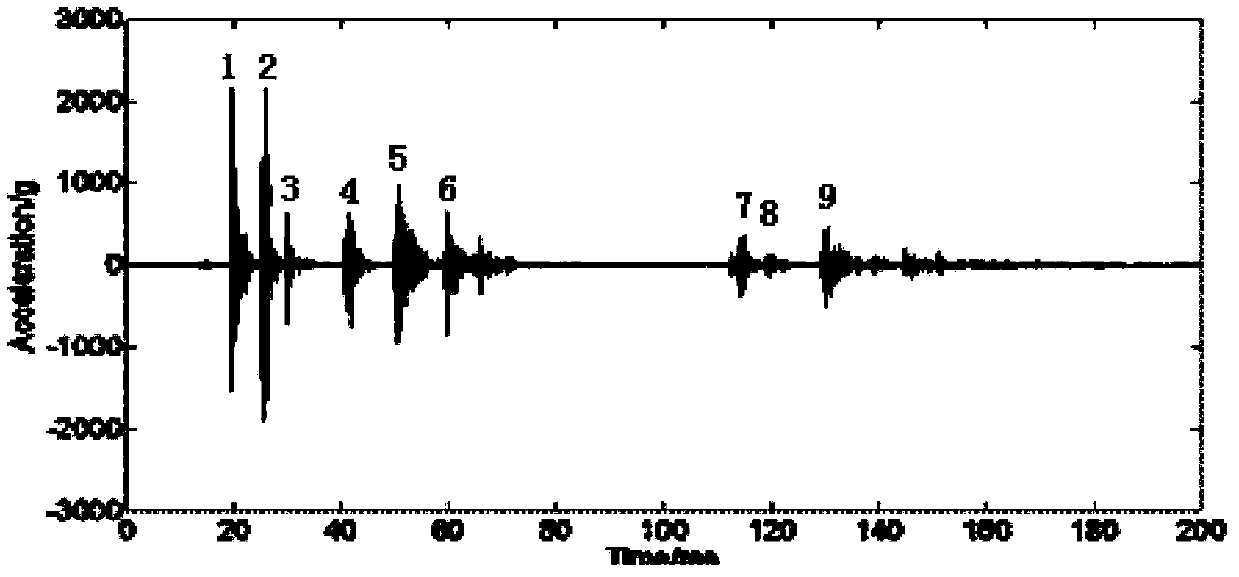

[0034] Such as figure 1 As shown, 1 is the ratchet, 2 is the closing latch, 3 is the opening latch, 4 is the electromagnet, 5 is the release piece, 6 is the support, 7 is the vibration sensor, 8 is the main arm, and 9 is the Cam, 10 is an opening and holding pawl, 11 is an electromagnet, and 12 is an opening latch. according to figure 1 The vibration sensor is installed as shown, the vibration signal is collected, the original vibration signal is processed by wavelet denoising, the noise of the experimental site is processed, and then the denoised waveform is processed by Hilbert transform and low-pass filtering to obtain a clear envelope spectral line. The vibration waveform during closing and opening process is as follows: image 3 , 4 shown.

[0035] Use the electrode method to determine the vibration events during the opening and closing process. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com