Liquid tank optimum design method based on load in severe sloshing inside liquid cargo ship

An optimized design, tank technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of not fully capturing the maximum load of tank sloshing, time-consuming calculation of tank sloshing load, and unbearable calculation time. The calculation speed is fast, the calculation time and efficiency are improved, and the calculation condition is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

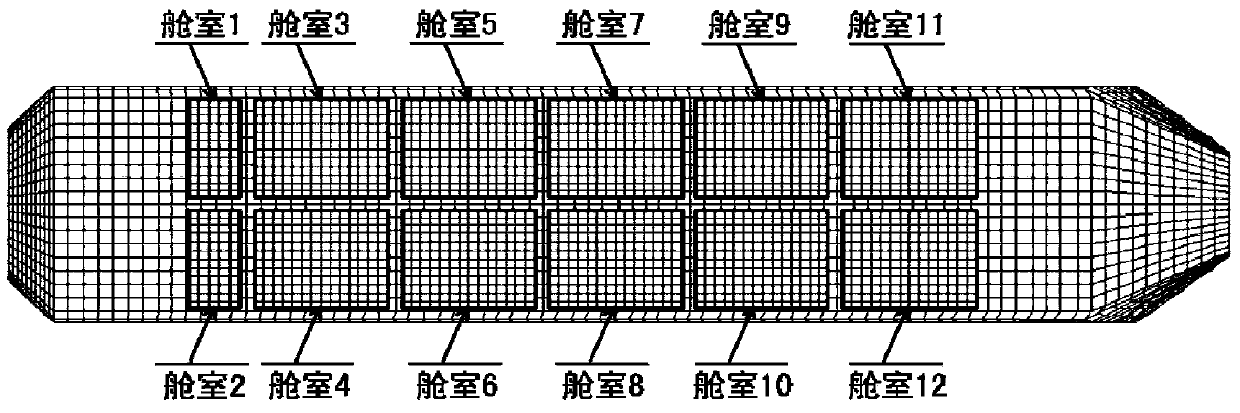

[0042] Such as figure 1 As shown, this embodiment takes FLNG, which is a recent research hotspot, as an example for illustration, where compartments 1-2 of the FLNG are LPG tanks, and compartments 3-12 are LNG tanks.

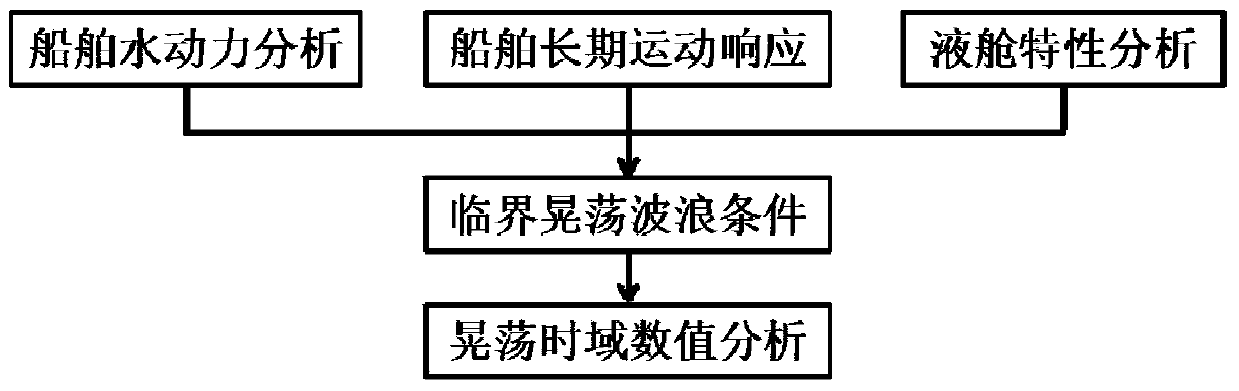

[0043] Such as figure 2 As shown, the present invention adopts the optimized design of the liquid tank structure type of the FLNG based on the violent sloshing load in the tank of the liquid cargo ship, and it comprises the following steps:

[0044] 1. Ship hydrodynamic analysis:

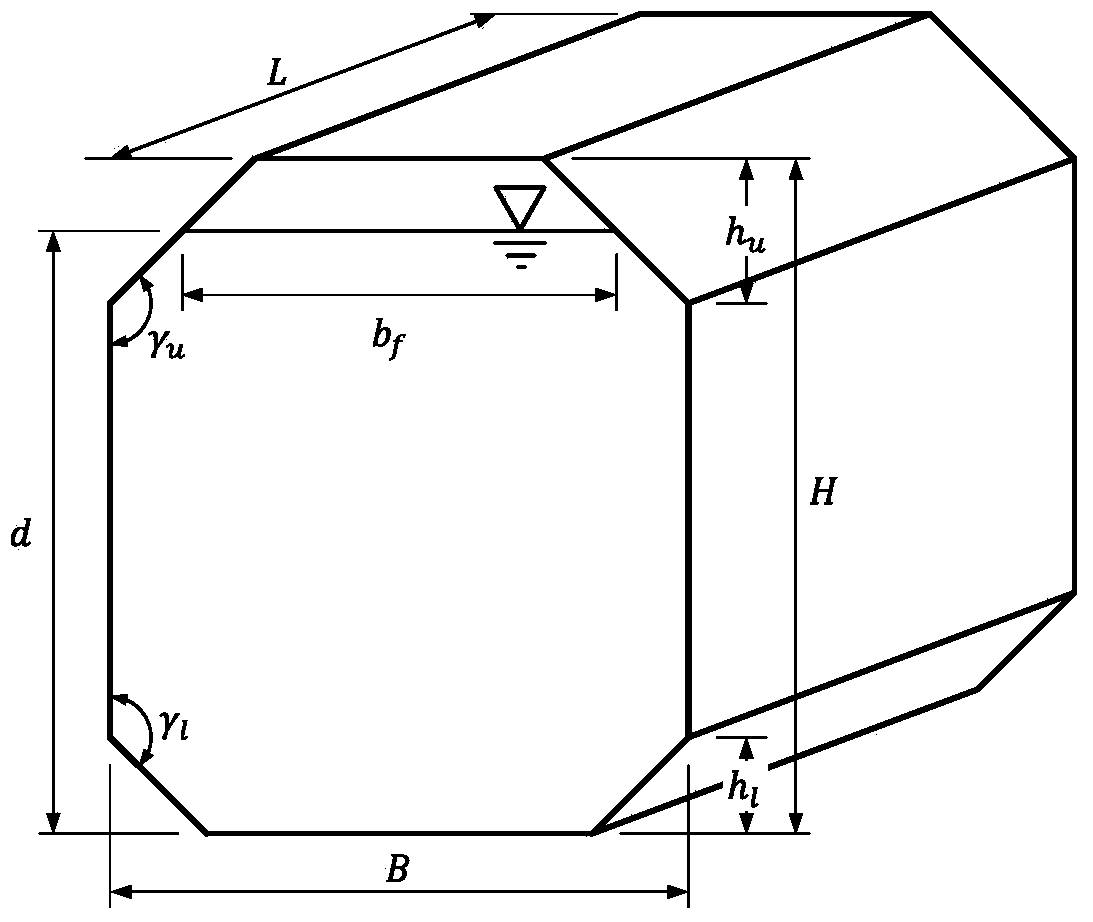

[0045] In order to analyze the hydrodynamic performance of FLNG, it is necessary to input the basic parameters of FLNG, such as the weight of the ship, the center of gravity, and the radius of inertia, and then use commercial software (such as HydroSTAR of BV company) to calculate the surge of each tank. , sway, heave, roll, pitch and slewing motion respo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com