A Printing Image Defect Detection Method Based on Region Combination Feature

A technology of printing images and combining features, which is applied in the field of image processing, and can solve problems such as low detection efficiency, heavy detection workload, and heavy template pre-extraction workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] In order to better illustrate the technical solution of the present invention, the present invention will be further described below through an embodiment in conjunction with the accompanying drawings.

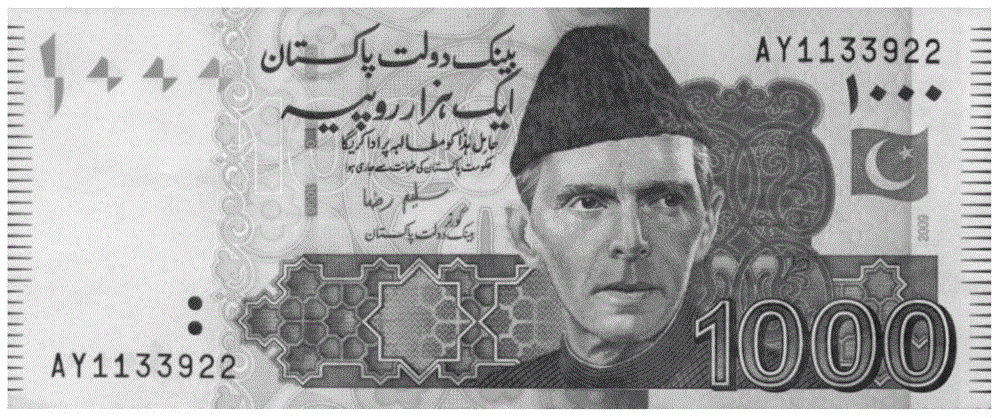

[0080] Using the printing image defect detection method based on the region combination feature proposed by the present invention to detect the defects of Pakistani banknotes with a face value of 1000 rupees, the operation steps are divided into two parts: a learning process and a training process.

[0081] The learning process is specifically:

[0082] Step 1. Carry out area division for the printing proof image. The specific steps are:

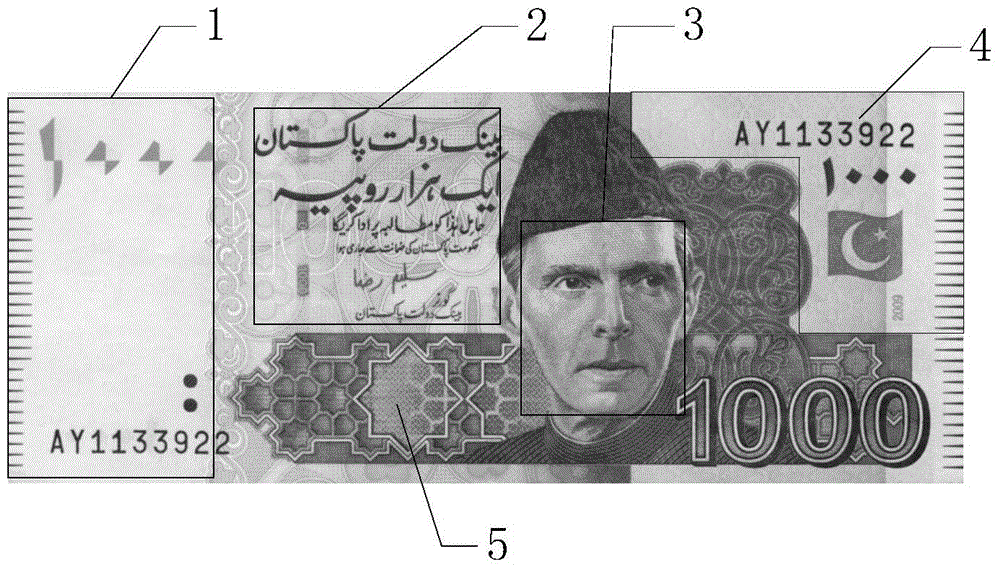

[0083] Step 1.1: Take the obverse of Pakistani banknotes of 1000 rupees as a printing proof image, such as figure 1 As shown, the printing sample image is manually divided into areas, and the text area 2 and the portrait area 3 in the obverse of the 1000 rupee banknote are designated as key areas, as shown in figure 2 shown; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com