Capacitor clamp

A technology for capacitors and fixtures, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as failure to ensure good contact between capacitors and charging wires, reduced accuracy and stability of sheath wires, and inability to realize automated production. Workload, improved stability and accuracy, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention are described in detail below:

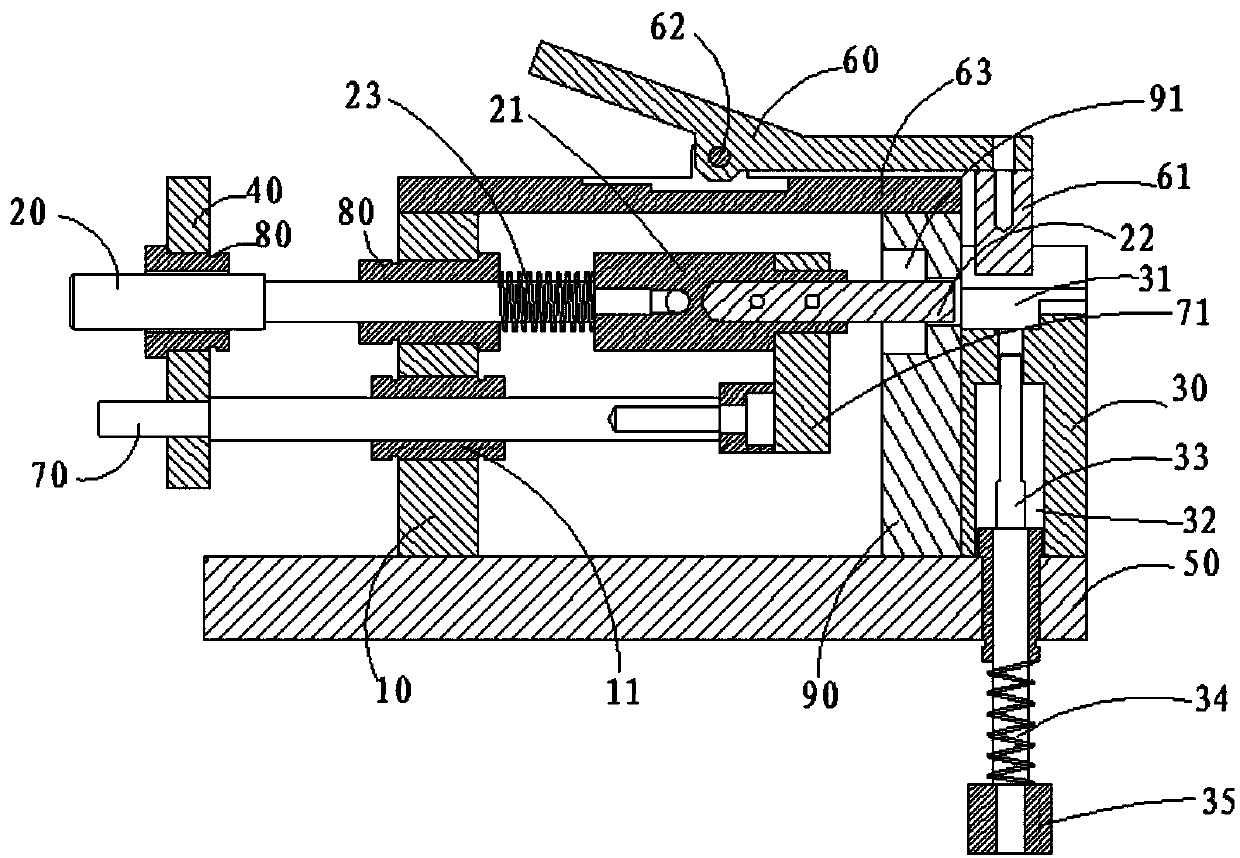

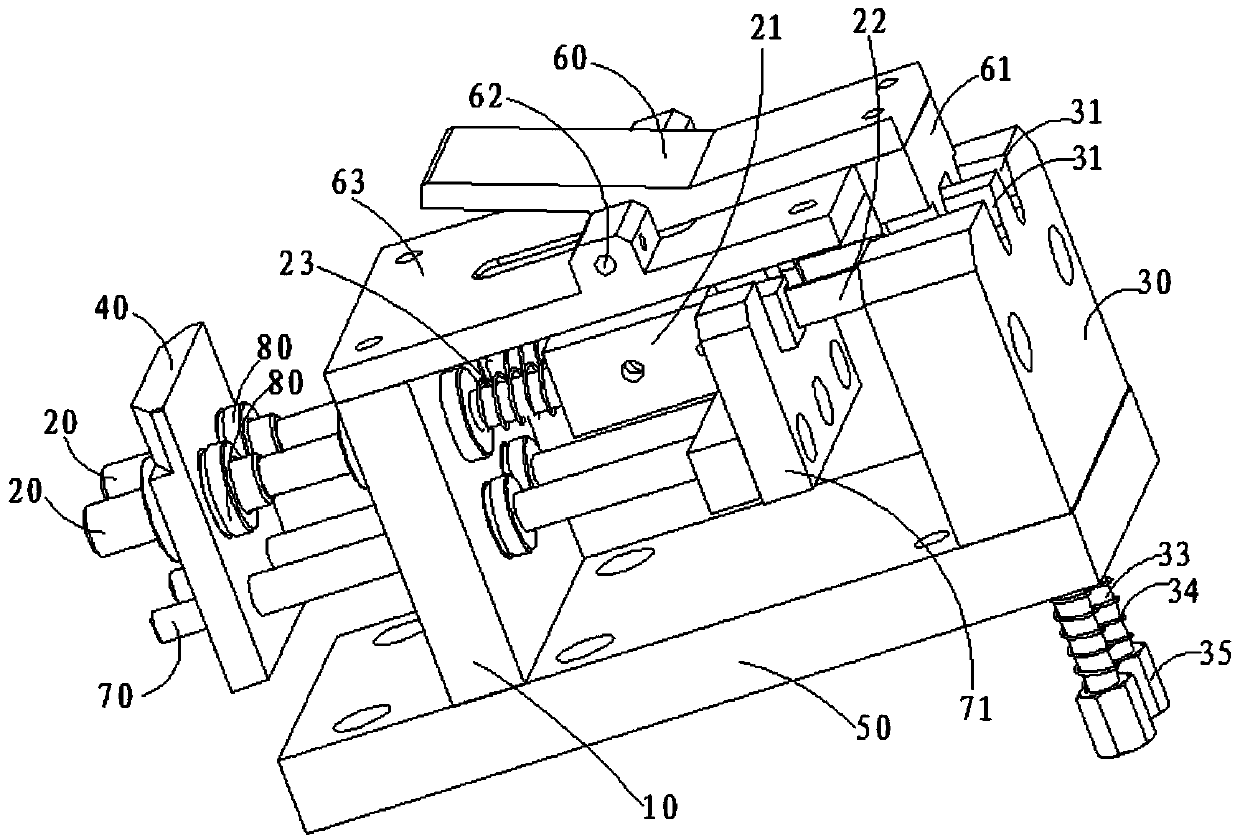

[0023] Such as figure 1 As shown, a capacitor fixture according to the present invention includes two conductive rods 20 and a first support plate 10. The first support plate 10 is provided with a first through hole for socketing the two conductive rods. Each conductive rod 20 is fixedly connected with a pull block 40, and also includes a lead end placement block 31, the lead end placement block 31 is provided with a lead end placement slot 31 corresponding to the first through hole, and the lead end placement slot 31 There are two, which are used to clip the charging terminal of the capacitor lead terminal.

[0024] Clamp the lead wire charging end of the sheath wire capacitor in the lead wire end placement groove 31, use a cylinder or hand to push the puller 40, and the pull block 40 drives the conductive rod 20 to electrically connect with the lead wire charging end of the sheath wire capacitor, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com