Eccentric separate-layer injection well holographic tester and test method

A tester and injection well technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems of heavy workload, achieve the effects of reducing expenses, reducing the workload of workers, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiment:

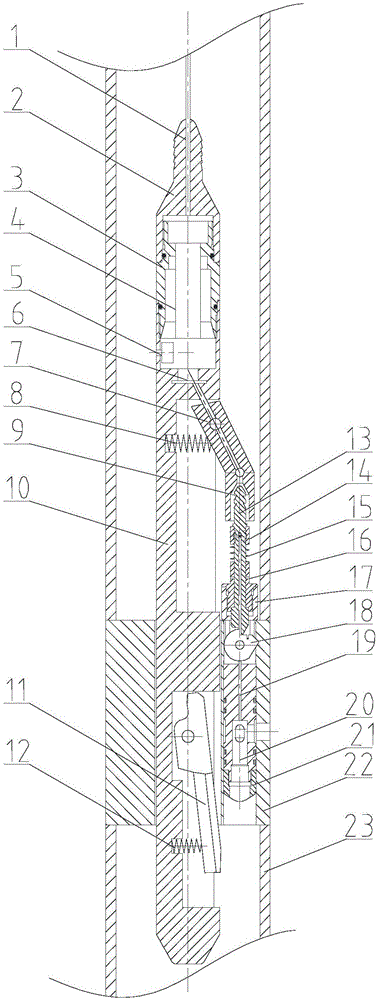

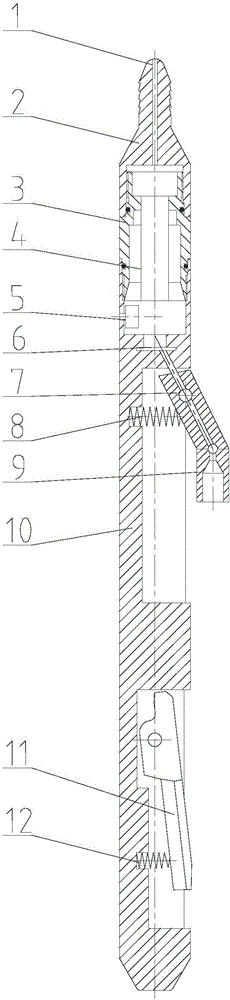

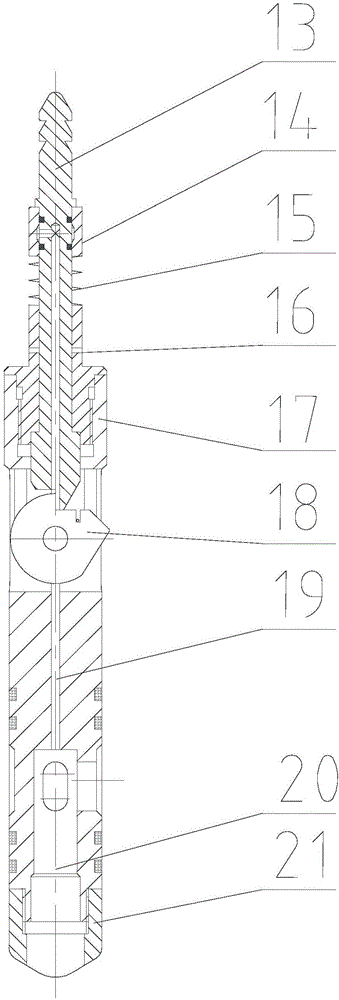

[0015] Such as figure 1 , figure 2 , image 3 As shown, a holographic tester for an eccentric layered injection well includes a downhole tester and a data acquisition plug. The downhole tester includes a rope cap 2 and a main body A10. The main body A10 is divided into two parts by an upper partition and a lower partition. There are three upper, middle and lower cavities, and an inclined hole is opened on the upper partition; the upper part of the rope cap 2 is connected to the cable 1, the core wire of the cable 1 is connected to the circuit board 4 at the lower part, and the rope cap 2 is connected to the outside of the circuit board 4 The lower part of the sheath 3 is connected to the main body A10, and the upper and lower sides of the upper cavity of the main body A10 are respectively equipped with a sensor A5 and a sensor B6. A spring A8 is radially fixed in the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com