Contactor polarized magnetic circuit structure

A technology of contactors and magnetic circuits, applied in circuits, relays, electromagnetic relays, etc., can solve the problems of poor mechanical environment resistance, limited application fields, and non-closed magnetic circuits, so as to prolong life, reduce arcing time, and enhance The effect of retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The polarized magnetic circuit structure of the contactor according to the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

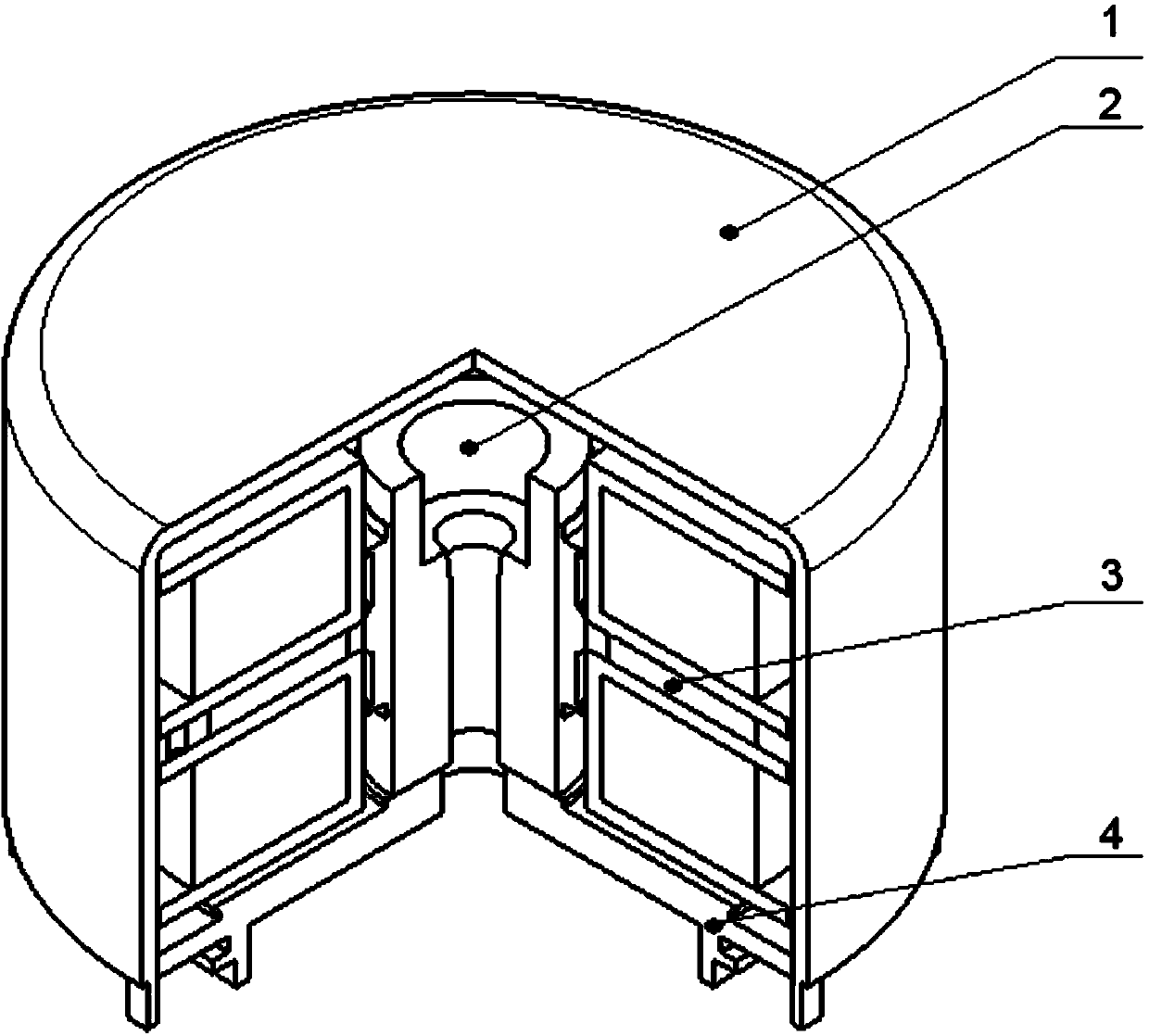

[0022] Such as figure 1 and figure 2 As shown, the polarized magnetic circuit structure of the contactor according to the present invention includes a magnetic permeable cover 1 , an armature 2 , an electromagnetic assembly 3 , and a yoke 4 . The electromagnetic component 3 is the source of electromagnetic and permanent magnetic forces in the magnetic circuit structure according to the present invention, and is also a part of the magnetic circuit. The magnetic permeable cover 1 and the yoke 4 provide a completely closed magnetic circuit. The armature is a movable part and can be kept in the set or reset position by the permanent magnetic force.

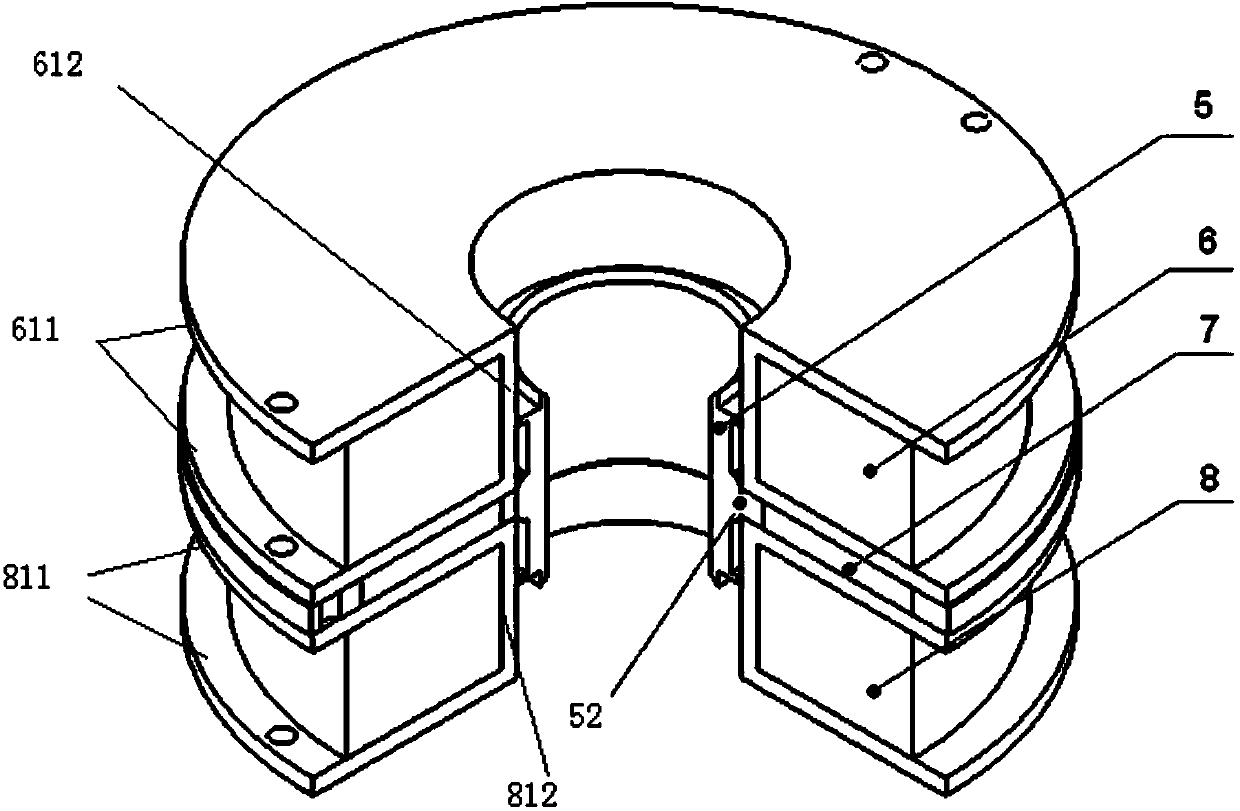

[0023] Specifically, such as Figure 1-Figure 7 As shown, in the preferred embodiment according to the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com