Magnetic driving mechanism and receiver

A technology of magnetic drive and receiver, which is applied in the direction of handset/headphone accessories, etc., can solve the problems of high difficulty in manufacturing process, small spacing, and the inability of the diaphragm to continue to vibrate, so as to achieve the effect of self-protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

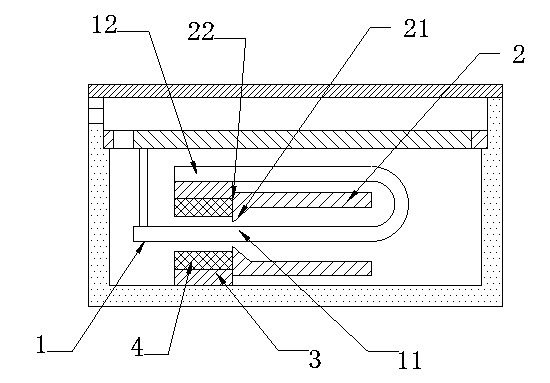

[0027] Such as figure 1 As shown, a receiver includes a magnetic drive mechanism. The magnetic drive mechanism includes a U-shaped armature 1, a coil 2 and an iron core 3. The U-shaped armature 1 includes a fixed part 12 and a vibration transducing part 11. The coil 2 and the iron core The core 3 is sleeved in the vibration transducing part 11 in turn, and the upper and lower sides of the vibration transducing part 11 are respectively provided with permanent magnets 4 fixedly connected to the inner surface of the iron core 3; the coil 2 is bonded to the iron core 3 to form a bond surface 22, the inner cavity of the coil 2 close to the adhesive surface 22 extends toward the vibration transducing part 11 to form a protruding part 21, and the distance between the protruding part 21 and the vibration transducing part 11 is smaller than the distance between the permanent magnet 4 and the vibration transducing part 11 The distance between the protrusions 21 and the coil 2 are integr...

Embodiment 2

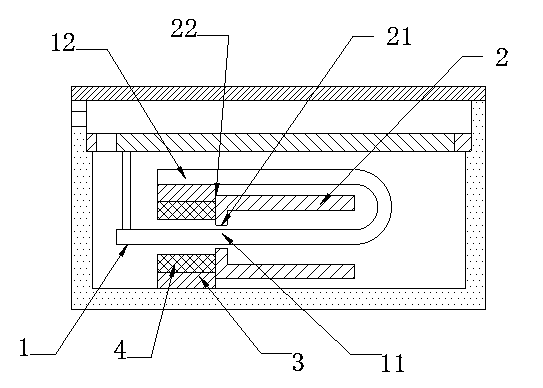

[0031] All the other are identical with embodiment 1, and difference is, as figure 2 As shown, the protruding part 21 of the coil 2 is a plane with respect to the surface of the vibration transducing part 11 .

[0032] Setting the surface of the protruding portion 21 relative to the vibration transducing portion 11 as a plane can effectively prevent the protruding portion 21 of the coil 2 from contacting the vibration transducing portion 11 of the armature 1 and causing damage to the armature due to the small contact surface. deformation.

[0033] Example 2

[0034] All the other are identical with embodiment 1, and difference is, as figure 2 As shown, the protruding part 21 of the coil 2 is a plane with respect to the surface of the vibration transducing part 11 .

[0035] Setting the surface of the protruding portion 21 relative to the vibration transducing portion 11 as a plane can effectively prevent the protruding portion 21 of the coil 2 from contacting the vibratio...

Embodiment 3

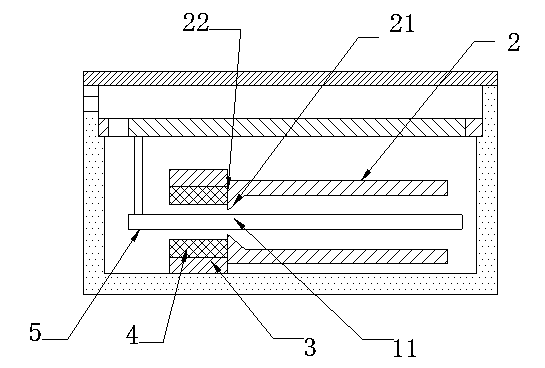

[0037] All the other are identical with embodiment 1, and difference is, as image 3 As shown, the armature 5 is an E-shaped armature, and the fixing portion 12 of the E-shaped armature 5 is fixedly connected to the outer surface of the iron core 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com