Set of multicomponent cartridges

A multi-component and two-component technology, applied in dispensing devices, containers with multiple items, packaging, etc., can solve problems such as huge changes, and achieve the effect of reducing the risk of cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

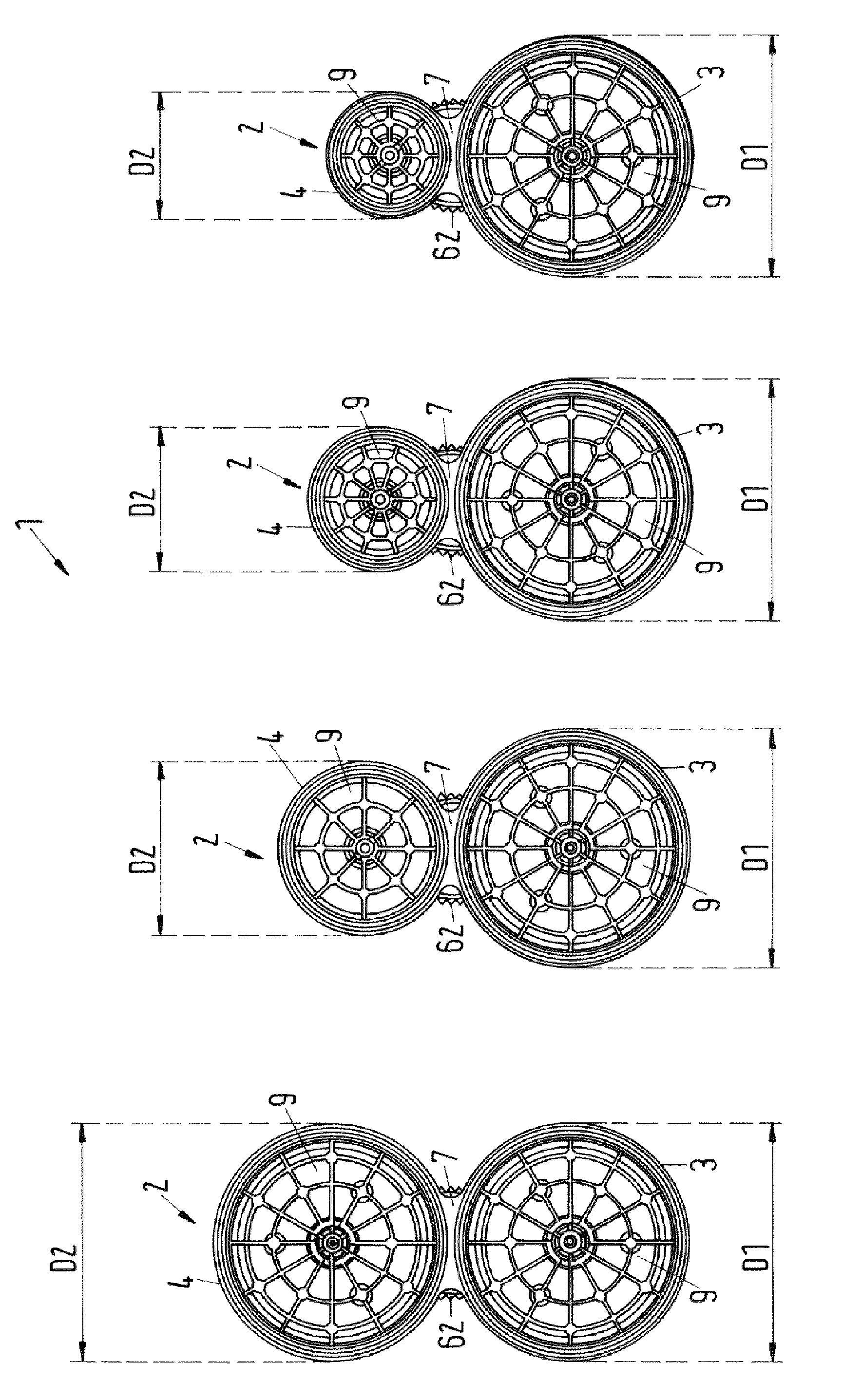

[0031] figure 1 A perspective view of an exemplary embodiment of a multi-component cartridge set according to the invention is shown, which is generally designated with the reference numeral 1 and here includes four multi-component cartridges 2 .

[0032]Reference is made below with exemplary features to the application which is particularly important for practice, namely that the multi-component cartridge 2 is correspondingly a two-component cartridge 2 . However, it is understood that the invention is not restricted to such a configuration, but can also include multicomponent cartridges 2 for more than two components in the same manner.

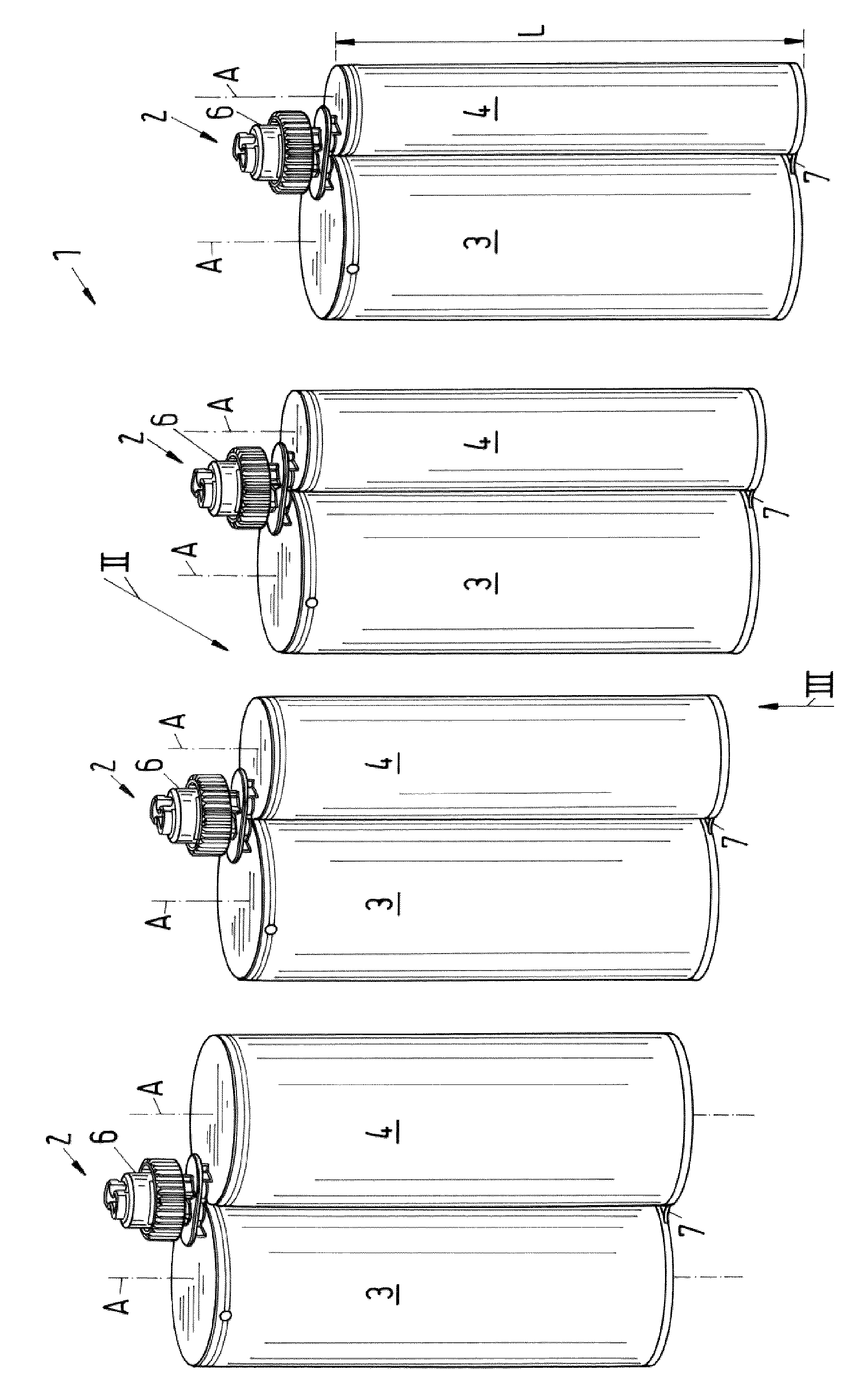

[0033] figure 2 show figure 1 From the barrel group 1 figure 1 The view seen in the direction indicated by arrow II.

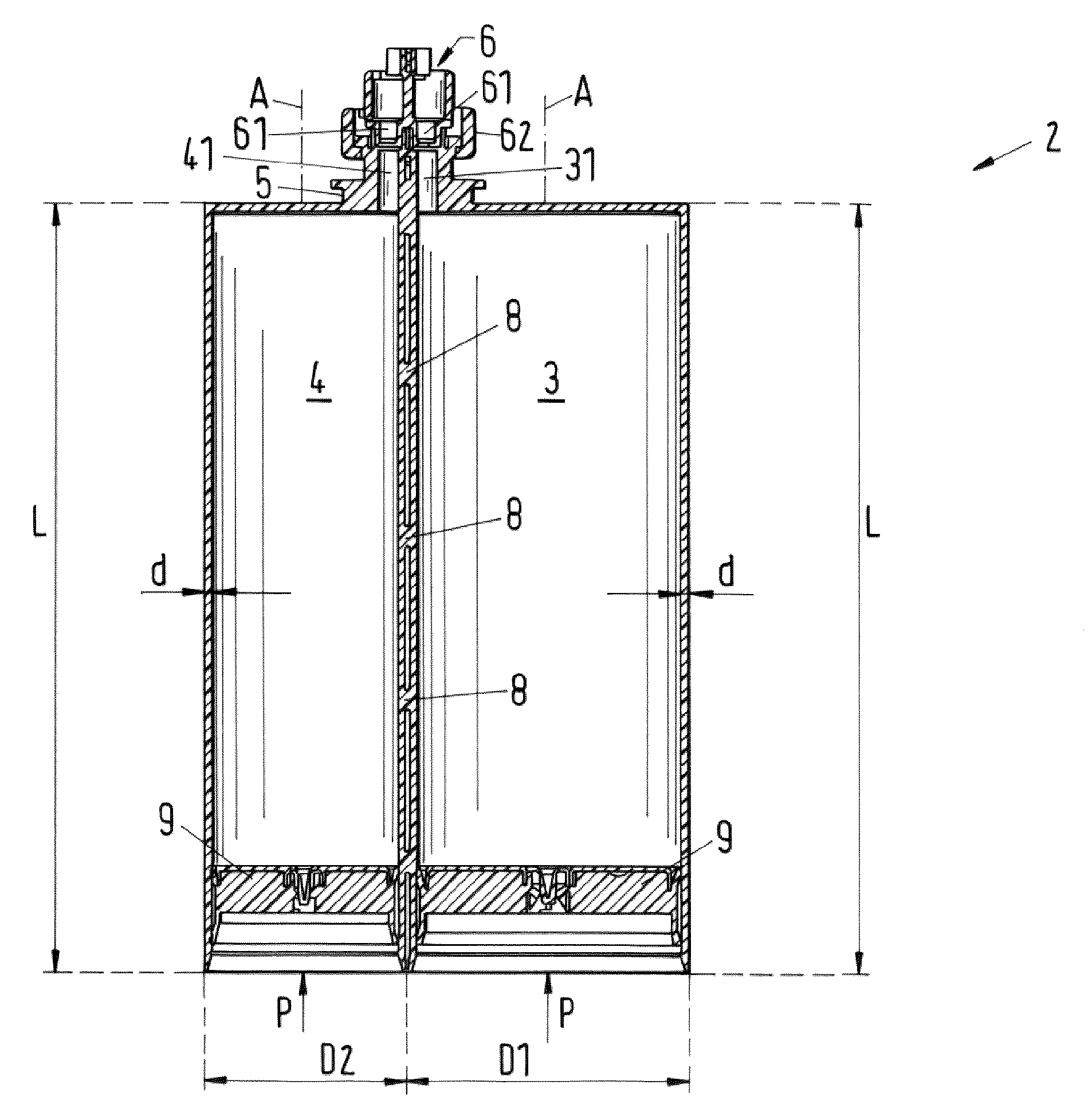

[0034] image 3 A view looking towards the bottom of the multi-component cartridge 2 is shown, ie from image 3 The view looking in the direction indicated by arrow III.

[0035] For better understanding, Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com