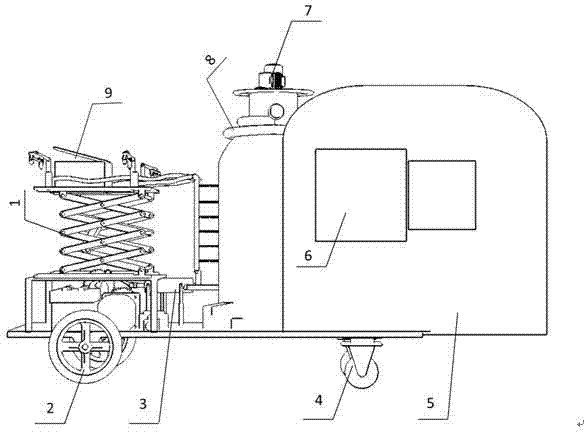

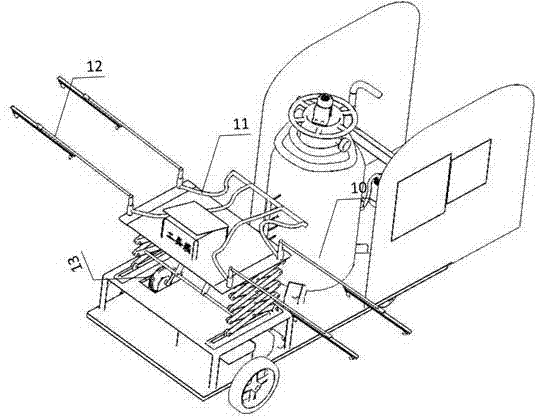

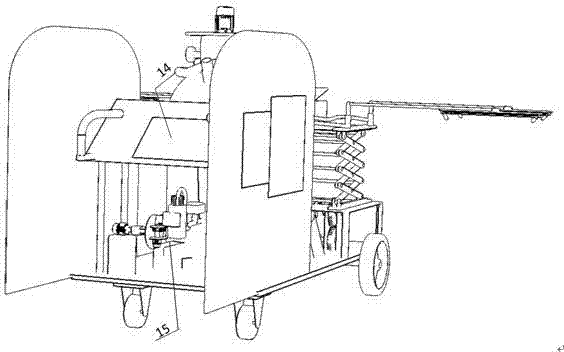

Novel semi-automatization pesticide spraying machine

A semi-automatic, spraying machine technology, applied in the device, application, animal husbandry, etc. of catching or killing insects, can solve the problems of mechanization, low degree of automation, high labor intensity, low effective utilization rate, etc., to achieve good promotion Value and economic significance, low cost, well-functioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

[0029] Working process of the present invention is as follows:

[0030] Automatic dispensing device ( Figure 4 As shown) the three-degree-of-freedom manipulator 19 is manipulated by the motor (1) 17 and the dispensing motor (2) 22 to realize the clamping of the dispensing bottle 21 and the flipping of the two degrees of freedom, etc., and cooperate with the flow control valve 24 to complete the full pesticide dispensing Automate the process.

[0031] Stirring drug storage device ( Figure 5 Shown) is made up of stirring medicine storage bottle 25, medicine storage outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com