Locating shaft for forming incisions

A technology for positioning shafts and cutting marks, which is applied in metal processing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

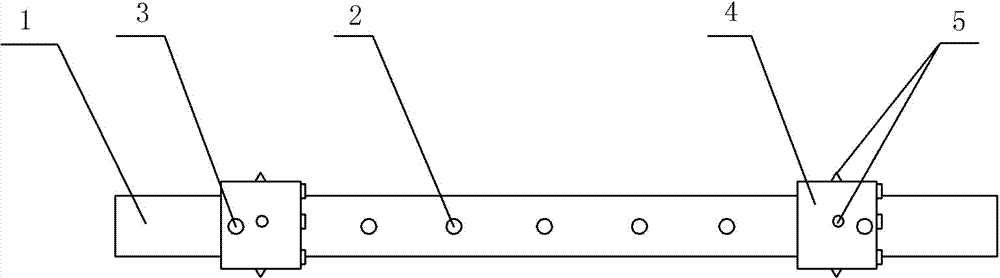

[0009] Such as figure 1 As shown, a positioning shaft for forming cut marks in this embodiment includes a positioning shaft body 1, and seven adjustment holes 2 are arranged on the positioning shaft body 1 along the axial direction, and connecting holes are provided on the shaft sleeve 4. A latch 3 is provided between the adjustment hole 2 and the connection hole, and a shaft sleeve 4 is sleeved on the positioning shaft body 1 . The shaft sleeve 4 is provided with a needle body 5 along the circumference of the positioning shaft body 1, the needle body 5 is divided into a needle head and a needle seat, the needle head faces the outer wall of the shaft sleeve 4, and the needle seat and the shaft sleeve 4 are connected by a spring.

[0010] Next, the working mode of this embodiment is described by taking the cut mark of the packaging bag as an example. First, fix the two bushings 4 on the positioning shaft body 1, install the positioning shaft for forming the easy-tear opening on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com