Hand-made cream making equipment with sugar sprinkling function

A cream and functional technology, applied in the field of hand-made cream making equipment, can solve the problems of large sugar particles, uneven mixing of sugar in hand-whipped cream, and inability to mix evenly, and achieve the effect of uniform sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

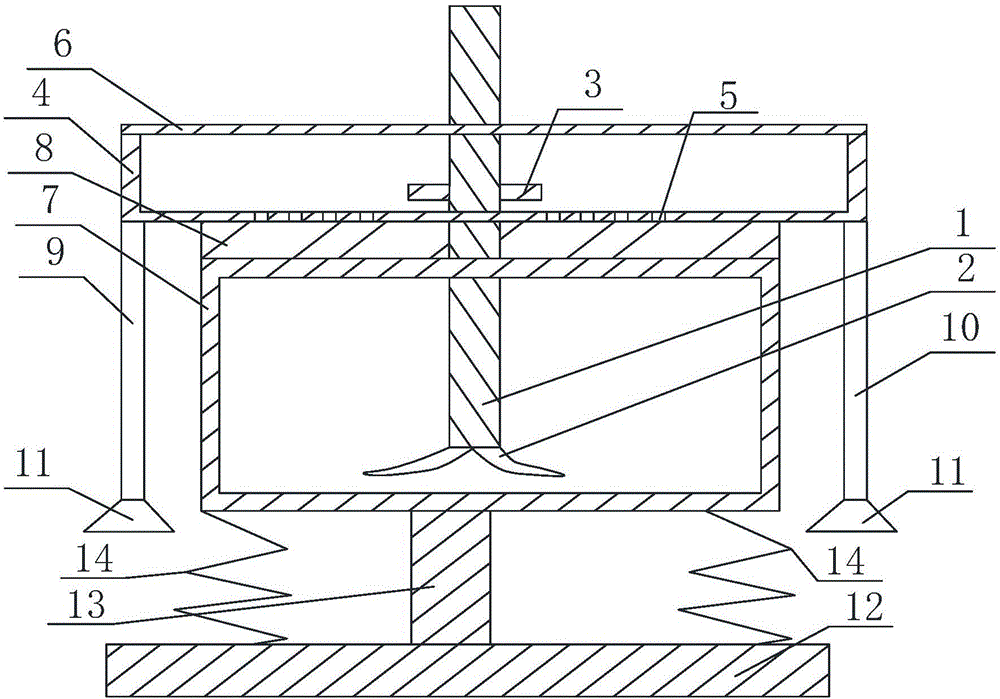

[0022] like figure 1 As shown, the present invention has a handcrafted cream production equipment with the function of sprinkling sugar, including a rotating shaft 1, on which a stirring blade 2 and a rotating knife 3 are installed, and the stirring blade 2 is located at the bottom of the rotating shaft 1, Rotary knife 3 is positioned at the top of stirring blade 2, and sugar box 4 is also set on the rotating shaft 1, and rotating shaft 1 is the central axis of sugar box 4, and rotary knife 3 is positioned at the inside of sugar box 4, and the box bottom of sugar box 4 is provided with multiple A leak hole 5, the bottom of the sugar box 4 is connected with a cream container 7, the stirring paddle 2 is located inside the cream container 7, the sugar box 4 and the cream container 7 are connected by a rubber ring 8, and the rubber ring 8 is fixed on the bottom of the sugar box 4 On the outer wall, the leak hole 5 communicates with the cream container 7. The box top of the sugar ...

Embodiment 2

[0025] Based on Embodiment 1, the below of the sugar box 4 is also connected with a fixing device, and the fixing device includes a first telescopic rod 9 and a second telescopic rod 10 respectively fixed on both sides of the sugar box 4. A suction cup 11 is fixed on the bottom, and the first telescopic rod 9 and the second telescopic rod 10 are mirror-image symmetric about the rotating shaft 1 . The suction cup is adsorbed on the desktop where the device is placed. The first telescopic rod and the second telescopic rod are used to adjust the height of the suction cup. The suction cup can fix the sugar box, and the sugar box will not shake violently to break away from the cream container during the crushing process of the sugar particles inside the sugar box.

Embodiment 3

[0027] Based on the above embodiment, a base 12 is installed under the cream container 7 , and the base 12 is connected to the cream container 7 through a third telescopic rod 13 , and the third telescopic rod 13 is located at the center of the cream container 7 . At least two springs 14 are also connected between the cream container 7 and the base 12 . The base is placed on the desktop, and the third telescopic rod is used to adjust the height of the cream container, that is, to adjust the height of the stirring device. The spring acts as a shock absorber to prevent the whole device from shaking during work and affect the connection stability of each part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com